A reverse pull rod pressure loading device

A loading device and tie-rod type technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of not being able to strictly ensure the uniformity of the circumferential fit, and the detachment of the fitting surface of the assembly stop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

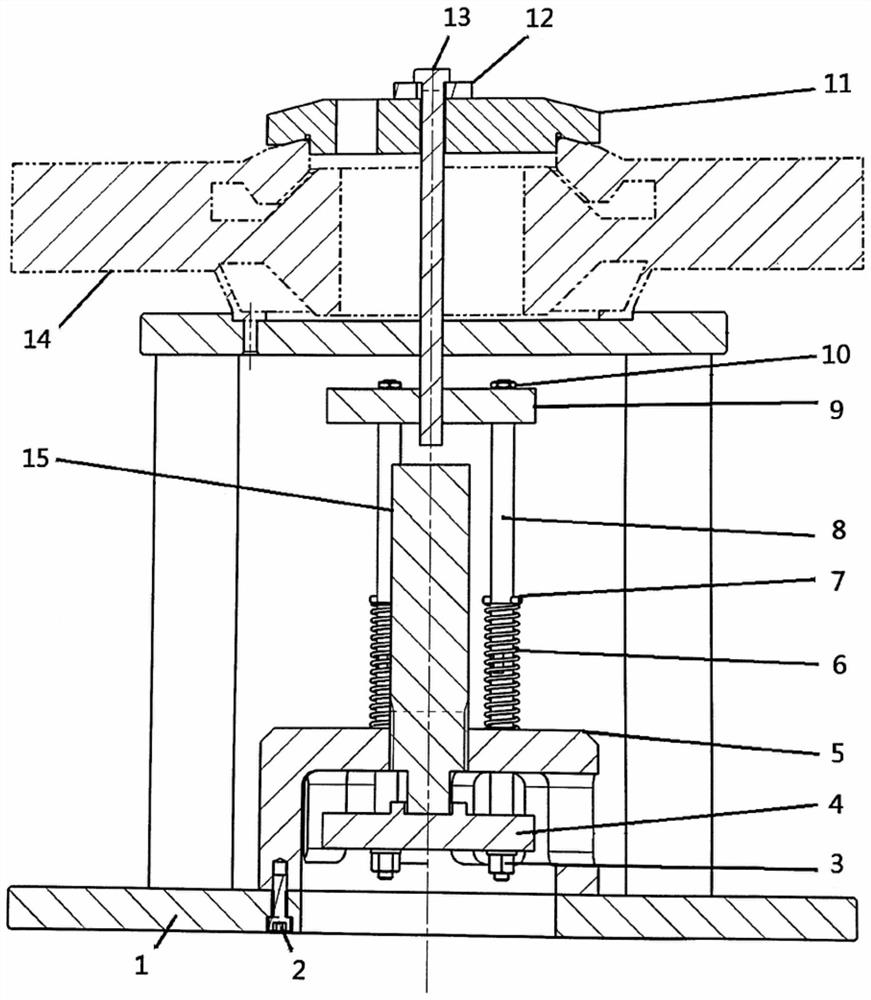

[0025] Such as figure 1 Shown is a reverse pull rod type pressure loading device, including a base 1, a top plate 4, a bracket 5, a compression spring 6, a cylindrical pin 7, a connecting rod 8, a floating plate 9, a gland 11, a stepped screw 12 and a jack 15;

[0026] The base 1 is frame-shaped, and forms a double-layer structure through the frame. The upper layer is provided with a disc-shaped seat for placing the disc part 14, and the inner end of the lower layer is connected to the bracket 5 through the hexagonal thin nut 2;

[0027] The disc part 14 is a short disc hollow structure;

[0028] The center of the support 5 is provided with a large threaded hole for installing the jack 15, and the circumference of the large threaded hole is provided with small holes;

[0029] After the connecting rod 8 passes through the small hole, the upper end is connected with the floating plate 9, locked and fixed by the hexagonal head bolt 10, and the lower end is connected with the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com