Rotating disc type watch glass lens detector

A glass lens and testing machine technology, which is applied to measuring devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve the problems of unsuitable watch glass lens turning over, unsuitable watch glass lens testing machine, etc. Achieve the effect of high degree of automation and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

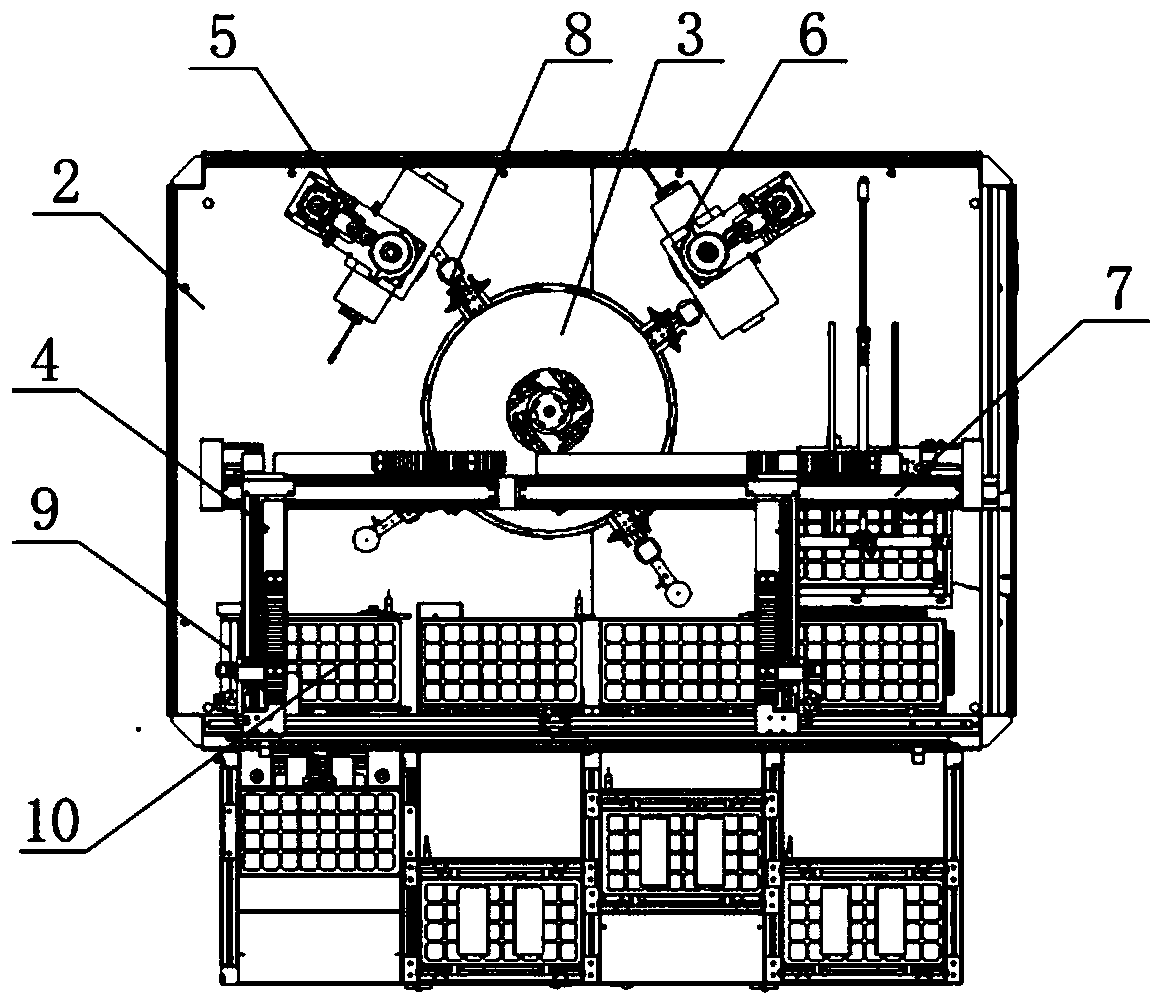

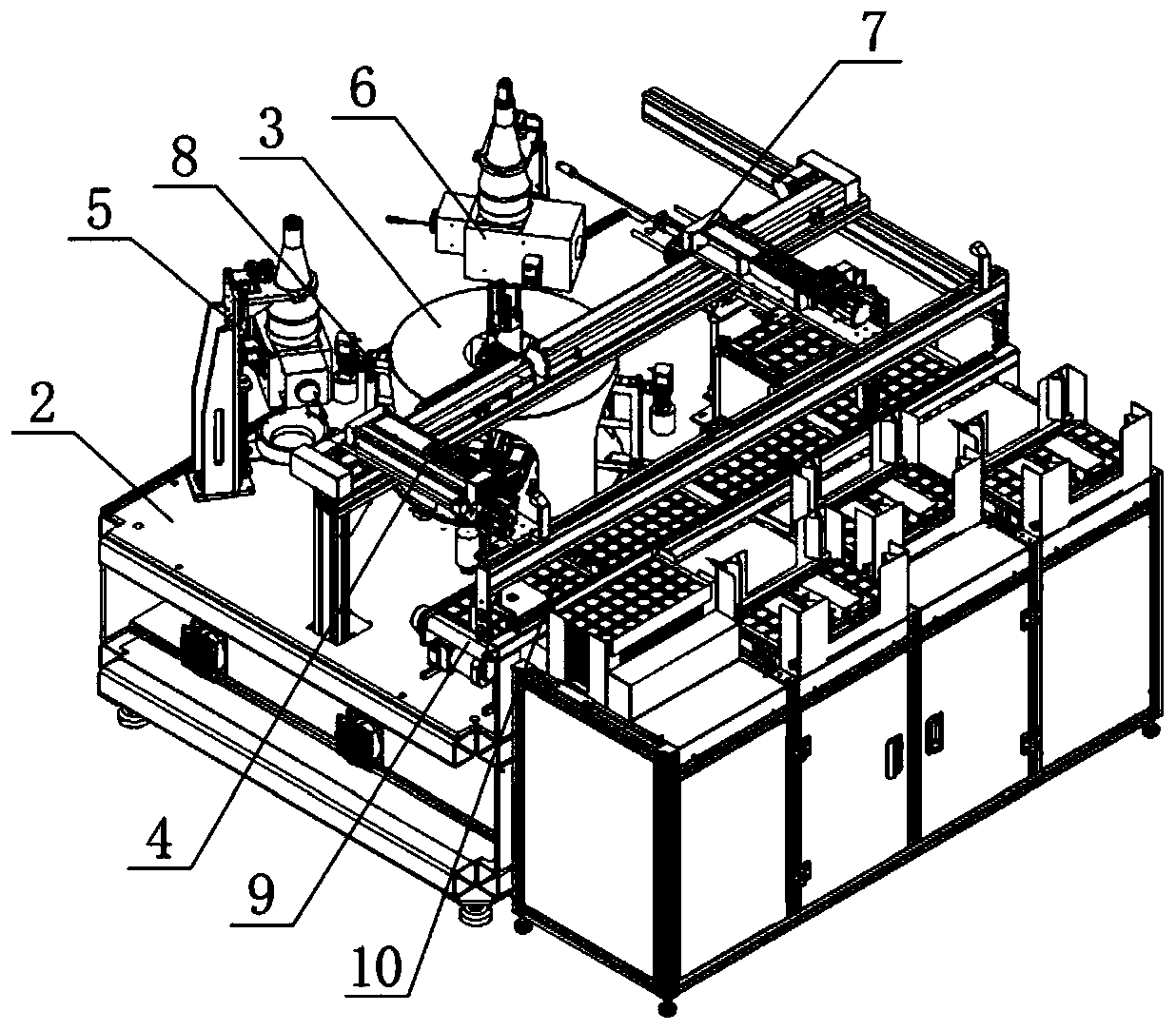

[0040] like figure 1 , 2 As shown in . Component 5, lens reverse detection camera component 6, unloading manipulator 7, material tray conveyor belt 9 and material tray 10, workbench 2 is set in box body 1, intermittent turntable 3 is installed on workbench 2, multiple lenses are turned over The surface adsorption carrier 8 is distributed and installed on the intermittent turntable 3, and the loading manipulator 4, the lens front detection camera assembly 5, the lens back detection camera assembly 6 and the unloading manipulator 7 are distributed on the intermittent turntable 3 in sequence, and the material tray The conveyor belt 9 is set on one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com