Agricultural fruit and vegetable cleaning device

A fruit and vegetable cleaning and agricultural technology, applied in application, filtration and separation, climate change adaptation, etc., can solve the problems of waste of water resources, time-consuming, inconvenient removal of fruits and vegetables, etc., and achieve the effect of recycling and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

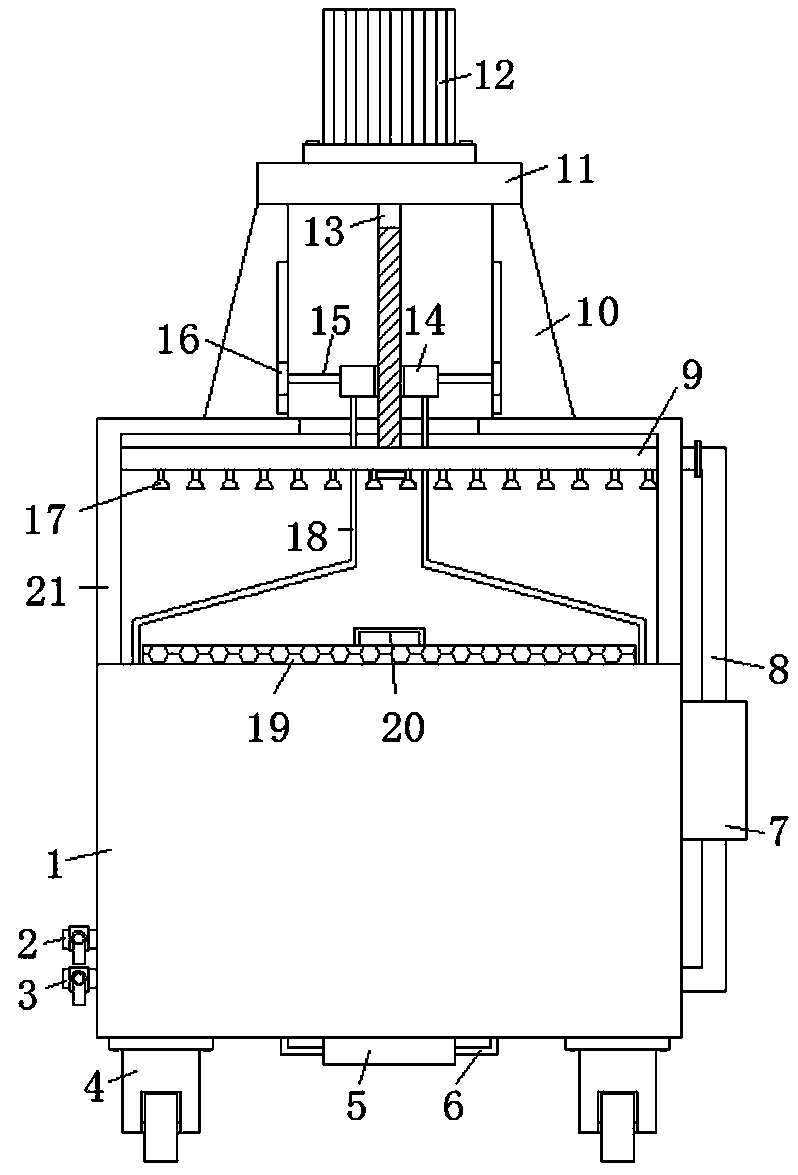

[0023] Embodiment one, with reference to figure 1 and figure 2 : An agricultural cleaning device for fruits and vegetables, comprising a box body 1, a U-shaped top plate 21 is welded on the box body 1, a bracket 10 is welded at the center of the top of the U-shaped top plate 21, a support plate 11 is welded on the top of the support plate 10, and the support plate The center of the top of 11 is fixed with a drive motor 12 by bolts. The model of the drive motor 12 is YE2-90L-2. The output end of the drive motor 12 is rotated with a threaded shaft 13, and the outer wall of the threaded shaft 13 is covered with a threaded sleeve. 14. Four fixed rods 18 are welded on the bottom of the threaded sleeve 14, and two L-shaped blocks 22 are welded on the bottom of the four fixed rods 18, and the two L-shaped blocks 22 are located in the box body 1, and the two L-shaped A net cage 19 is arranged between the blocks 22, and a handle 20 is welded on the top of the net cage 19. The handle ...

Embodiment 2

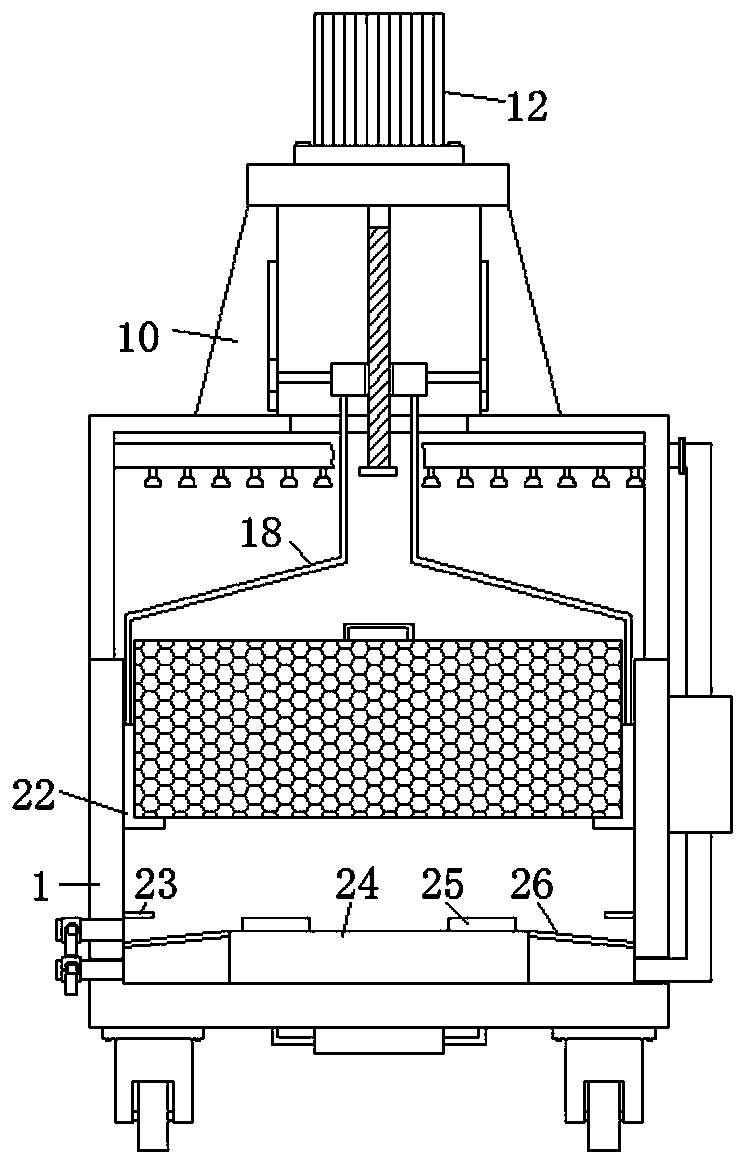

[0024] Embodiment two, refer to Figure 2-4 : Weld limit block 23 on the inner wall of casing 1, and limit block 23 is positioned at the top of projection 24, so that the descending height of net cage 19 is limited by limit block 23, the inner wall top of casing 1 is welded with convex block 24, and the top of the bump 24 is welded with two jet pipes 25, the bottom center of the box body 1 is fixed with an air pump 5 by bolts, the model of the air pump 5 is RB-81D-2, and the output end of the air pump 5 passes through the air pipe 6 is communicated with the air jet pipe 25, so that air is sent to the box body 1 through the air pump 5, so that the cleaning water in the box body 1 rolls, and the two air jet pipes 25 are all layered back into shape, and the tops of the two air jet pipes 25 are connected to be provided with A plurality of unidirectional air jets 27, when the net cage 19 moved downwards into the casing 1, the stop block 23 provided could limit the descending height...

Embodiment 3

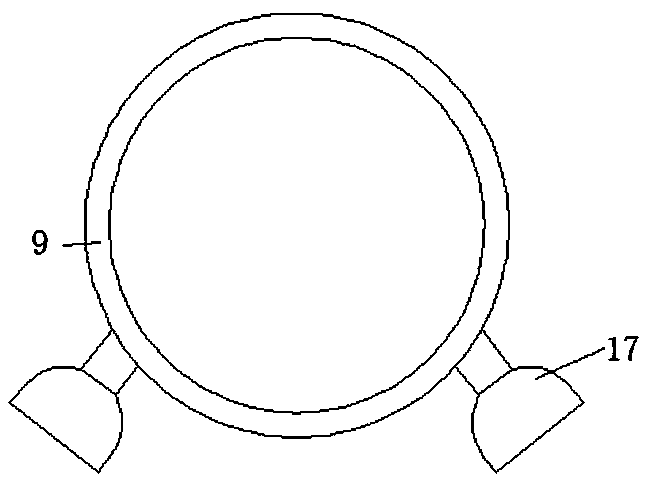

[0025] Embodiment three, refer to figure 2 and Figure 5 : The inner wall of the box body 1 is welded with a filter screen plate 26, and the filter screen plate 26 is welded to the bump 24, and the filter screen plate 26 is inclined, and one side of the box body 1 is connected to the two sides of the filter screen plate 26 respectively A slag discharge pipe 2 and a drain pipe 3 are provided, and control valves are arranged on the slag discharge pipe 2 and the discharge pipe 3, and the impurities generated by filtration can be removed through the slag discharge pipe 2, so that the cleaning water can be filtered through the filter plate 26. Filtration process, the U-shaped top plate 21 is horizontally penetrated with a water spray pipe 9, and the bottom of the water spray pipe 9 is connected with a plurality of water spray heads 17, and a plurality of water spray heads 17 are inclined to both sides, so that To achieve better cleaning of fruits and vegetables, one side of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com