Secondary fermentation preparation method for red sour soup

A technology of secondary fermentation and production method, applied in the direction of bacteria, food science, and application used in food preparation, can solve the problems of prolonging the shelf life, long fermentation period, complicated production process, etc., to increase the acidity of the product and simplify the fermentation process. , the effect of the production method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

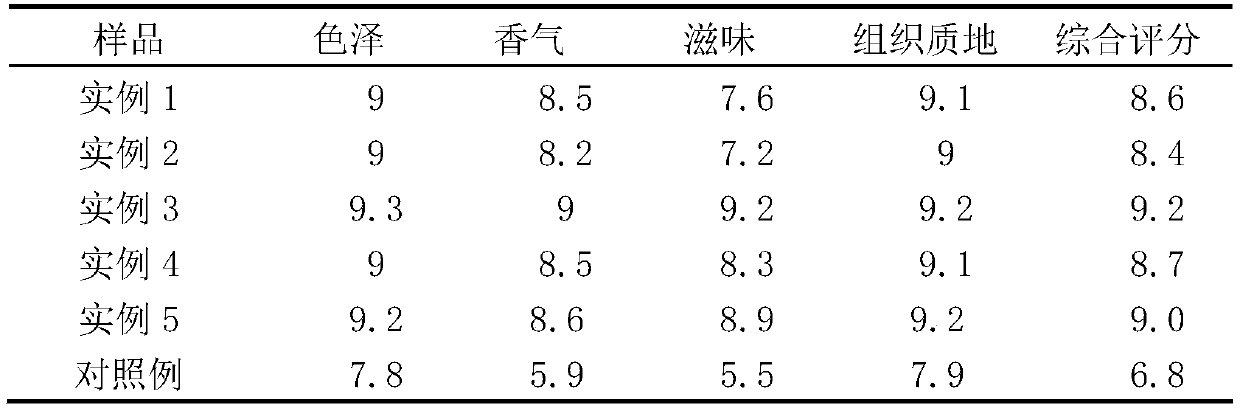

Embodiment 1

[0028] Include the following steps:

[0029] (1) Primary fermentation of tomatoes: select "Fangu No. 1" tomatoes under the brand of "Fangu Guizhen" as raw materials, wash and remove the stems, and soak in 15% salt water for 20 minutes to remove floating foreign objects and dust impurities; Then put the tomatoes into slightly boiling clear water for a few tens of seconds until the skins are slightly cracked and quickly removed to remove the skins and bacteria; after draining and peeling, crush them into pulp juice; Process tomato juice, add the Lactobacillus plantarum M-10439 of 0.06 weight part, the Lactobacillus rhamnosus LV108 of 0.09 weight part, the edible salt of 5 weight parts, the white granulated sugar of 0.5 weight part, the white wine of 3 weight parts, mix evenly, Fermentation at a constant temperature of 23°C for 23 days to obtain a tomato fermented sample with a soluble solid content of 9.2-9.5% and an acidity (calculated as lactic acid) of 0.8-1.0%. Note: For de...

Embodiment 2

[0035] Include the following steps:

[0036] (1) Primary fermentation of tomatoes: select "Fangu No. 1" tomatoes under the brand "Fangu Guizhen" as raw materials, wash and remove the stems, and soak in 10% salt water for 30 minutes to remove floating foreign objects and dust impurities; Then put the tomatoes into slightly boiling clear water for a few tens of seconds until the skins are slightly cracked and quickly removed to remove the skins and bacteria; after draining and peeling, crush them into pulp juice; Process tomato juice, add 0.12 parts by weight of Lactobacillus plantarum M-10439, 0.08 parts by weight of Lactobacillus rhamnosus LV108, 5 parts by weight of edible salt, 0.35 parts by weight of white sugar, 2 parts by weight of white wine, mix evenly, Fermentation at a constant temperature of 27°C for 20 days to obtain a tomato fermented sample with a soluble solid content of 8.5-9.2% and an acidity (calculated as lactic acid) of 0.7-1.0%. Note: For details of Lactob...

Embodiment 3

[0042] Include the following steps:

[0043] (1) Primary fermentation of tomatoes: select "Fangu No. 1" tomatoes under the brand of "Fangu Guizhen" as raw materials, wash and remove the stems, and soak in 12.5% salt water for 25 minutes to remove floating foreign matter and dust impurities; Then put the tomatoes into slightly boiling clear water for a few tens of seconds until the skins are slightly cracked and quickly removed to remove the skins and bacteria; after draining and peeling, crush them into pulp juice; Process the tomato juice, add 0.06 parts by weight of Lactobacillus plantarum M-10439, 0.04 parts by weight of Lactobacillus rhamnosus LV108, 5 parts by weight of edible salt, 0.5 parts by weight of white sugar, 3 parts by weight of white wine, mix evenly, Fermentation at a constant temperature of 25° C. for 20 days to obtain a tomato fermented sample with a soluble solid content of 8.8-10.0 percent and an acidity (calculated as lactic acid) of 0.9-1.2 percent. N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com