High Tolerance Floating Mating Connector Housing Assembly

A large-tolerance floating docking and connector technology, which is applied to the device for joining/disconnecting connected parts, parts of the connecting device, connections, etc., can solve the problem of high connector prices, connectors that do not have a sealing function, and cannot be normal Work and other issues, to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

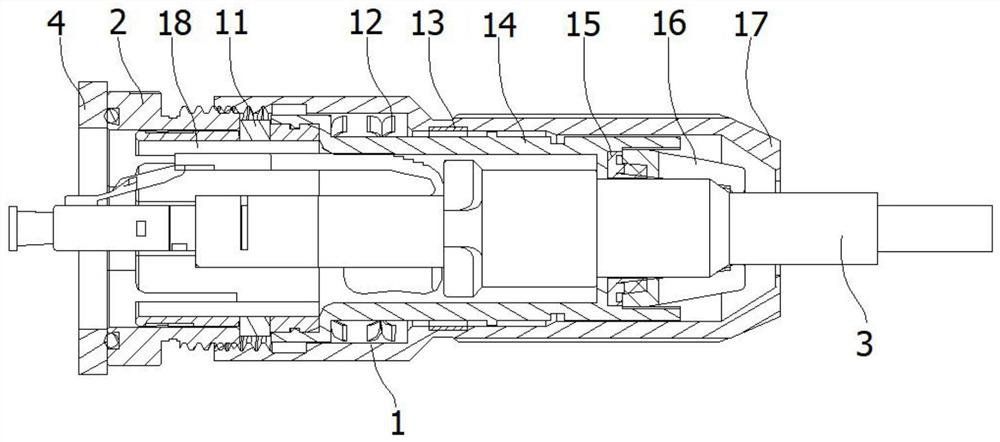

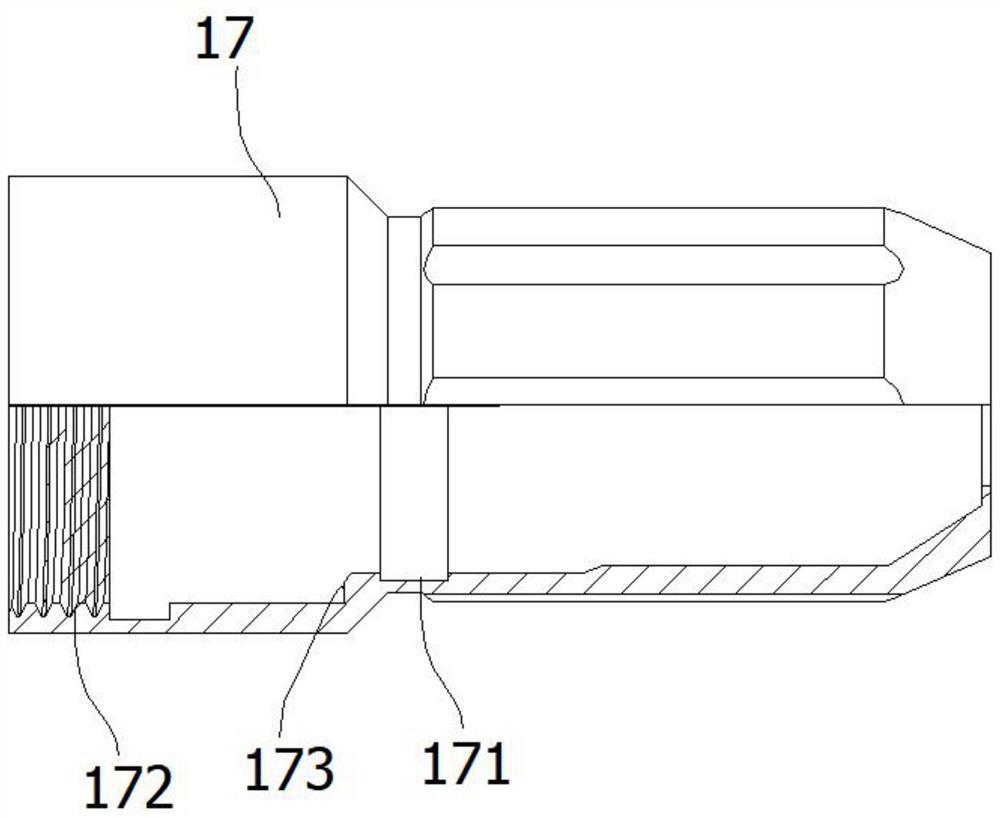

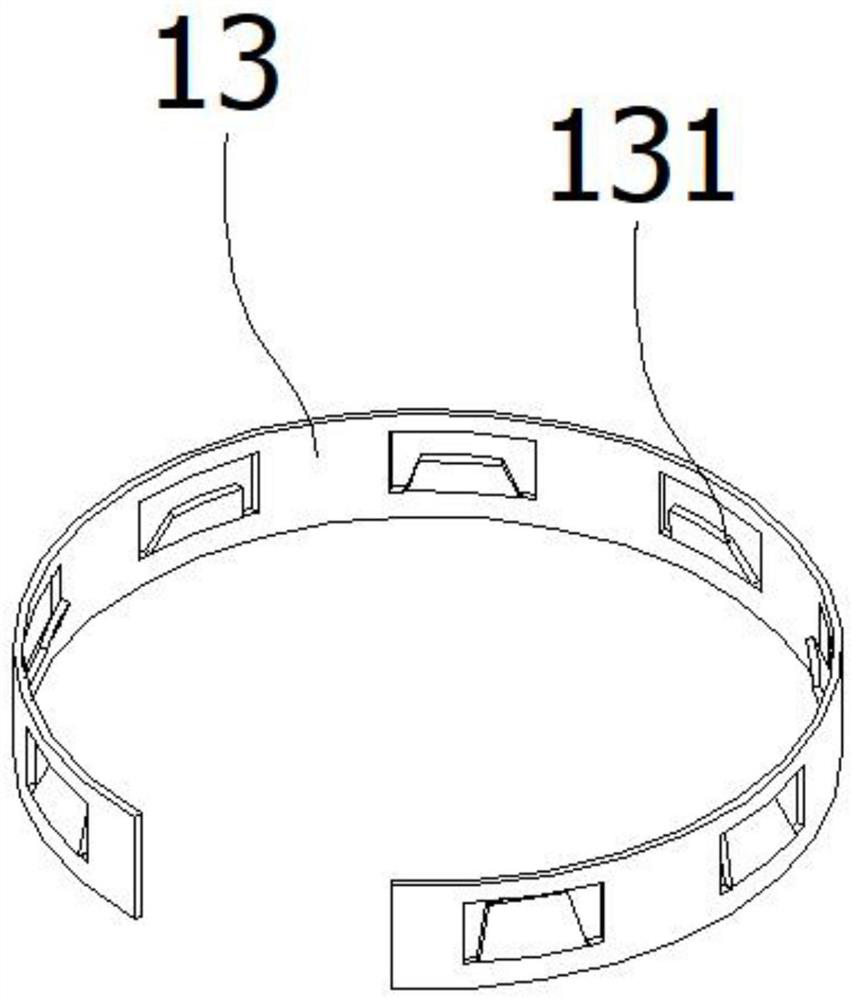

[0025] Large-tolerance floating butt joint connector shell assembly, including a shell assembly 1 and a socket assembly 2, the shell assembly 1 includes a guide sleeve 18, an inner sleeve 14 and a shell 17, and the inner section of the shell 17 forms a stepped structure A step 173, and an inner thread 172 is provided on the inner side of one end of the housing 17; a wave washer 12 is placed in the step 173; a collar 141 is provided at the other end of the inner sleeve 14, and the collar 141 The end is connected to the guide sleeve 18, the end of the inner sleeve 14 away from the guide sleeve 18 is inserted into the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com