A sliding installation device with compensation mechanism for remote sensing scanning mirror

A technology of compensation mechanism and installation device, which is applied in the field of remote sensing scanning mirrors, can solve problems such as difficulty in satisfying sliding and angle adjustment, difficulty in compensating satellite attitude deviation information, etc., and achieves the effects of facilitating scanning, reducing maintenance costs, and simple sliding structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

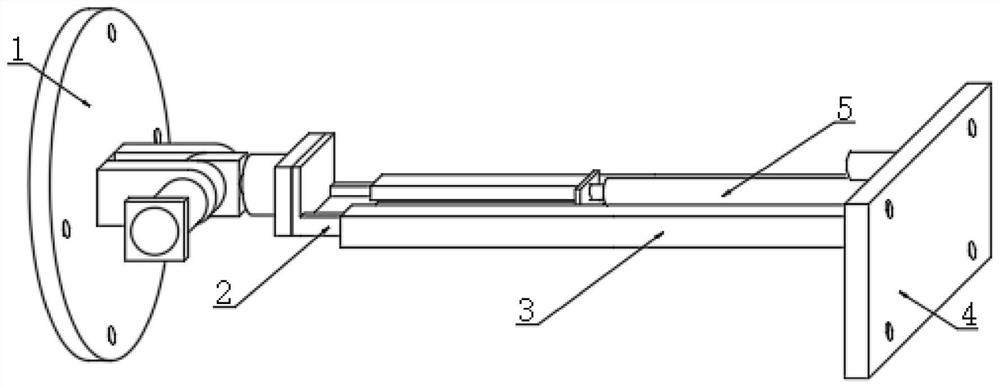

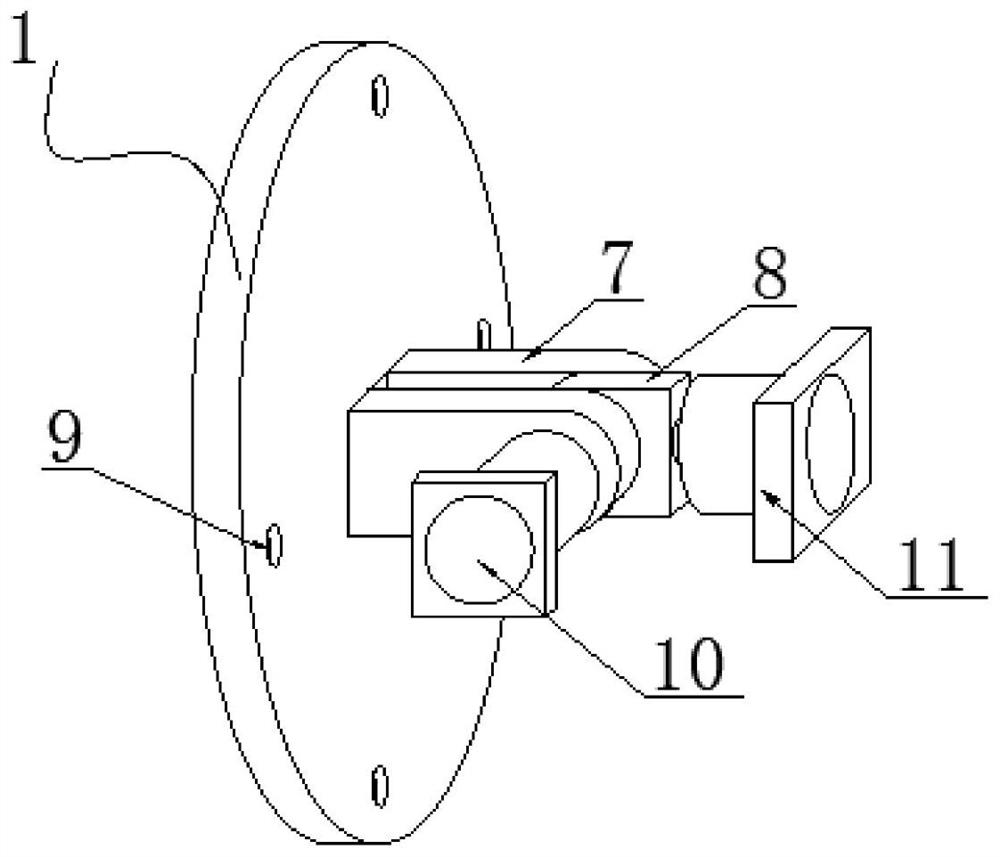

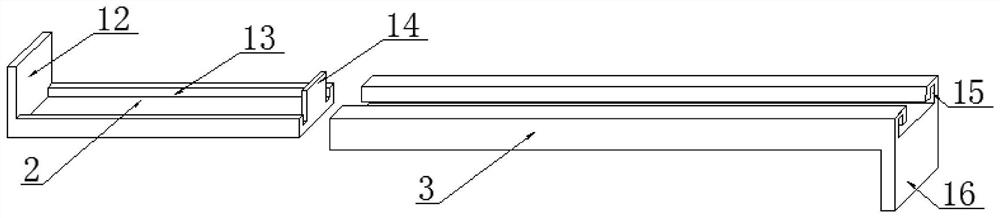

[0024] see Figure 1~5 , in an embodiment of the present invention, a sliding mounting device with a compensation mechanism for a remote sensing scanning mirror, including a remote sensing scanning mirror mounting head 1, a mounting positioning seat 4, a sliding telescopic mechanism, a first rotation mechanism and a second rotation mechanism , wherein one end of the sliding telescopic mechanism is installed on the installation positioning seat, the other end of the sliding telescopic mechanism is fixedly connected to the first rotating mechanism, and the first rotating mechanism is connected to the The remote sensing scanning mirror installation head 1 is characterized in that the first rotating mechanism and the second rotating mechanism are provided with an accuracy compensation component; The rotated angles of the first rotating mechanism and the second rotating mechanism are precisely compensated, and the range of the angle compensated by the precision compensating compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com