Wall surface panel for fabricated building and wall surface structure

An architectural and prefabricated technology, applied in building construction, construction, covering/lining, etc., can solve the problems of low flexural strength and surface hardness, poor durability, heavy solid wall panel weight, etc., to achieve light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

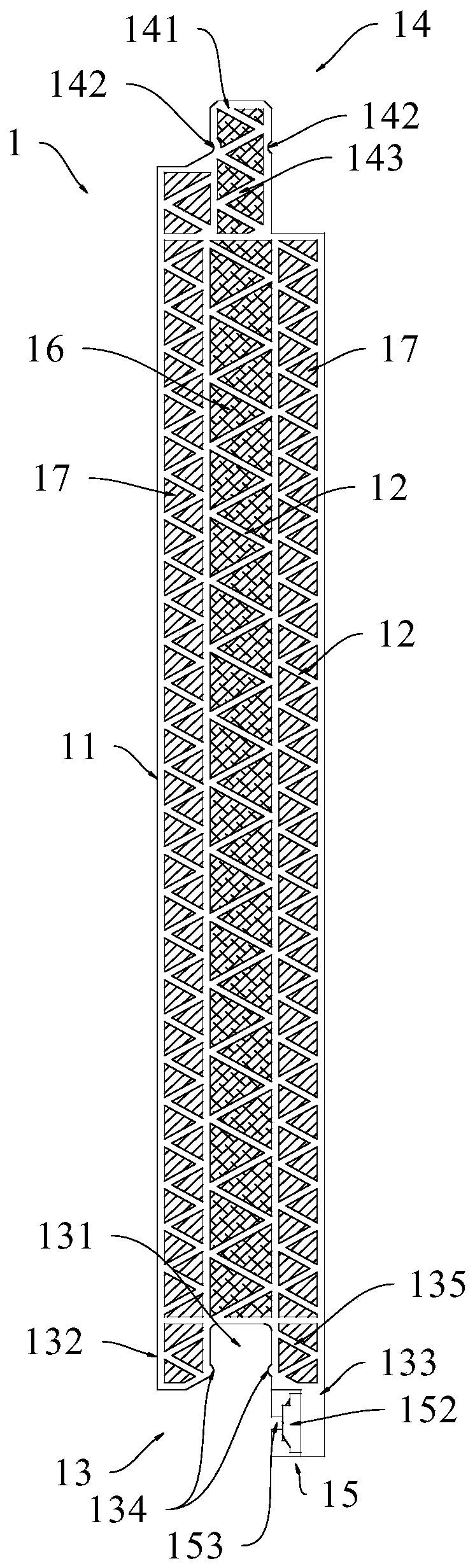

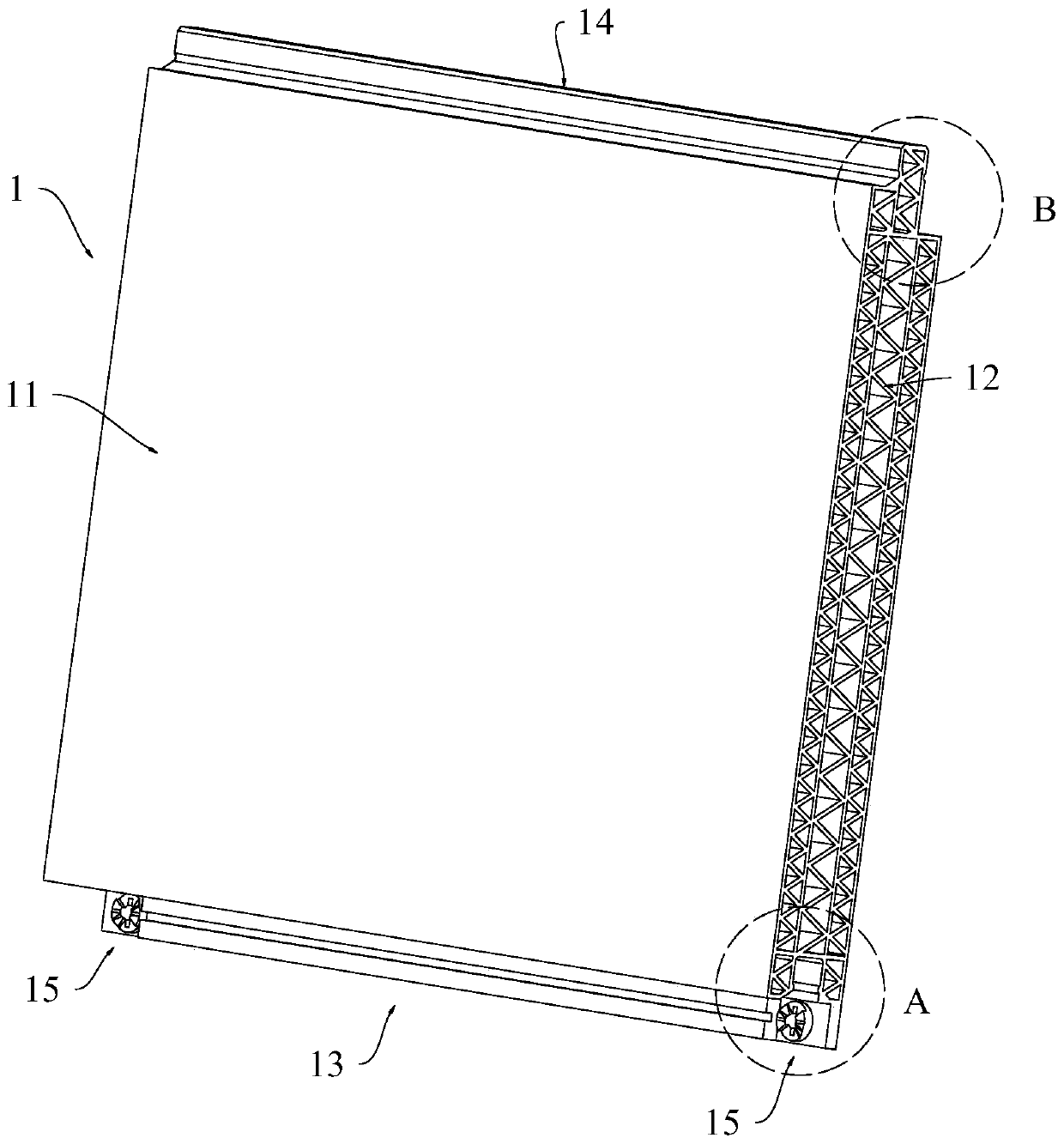

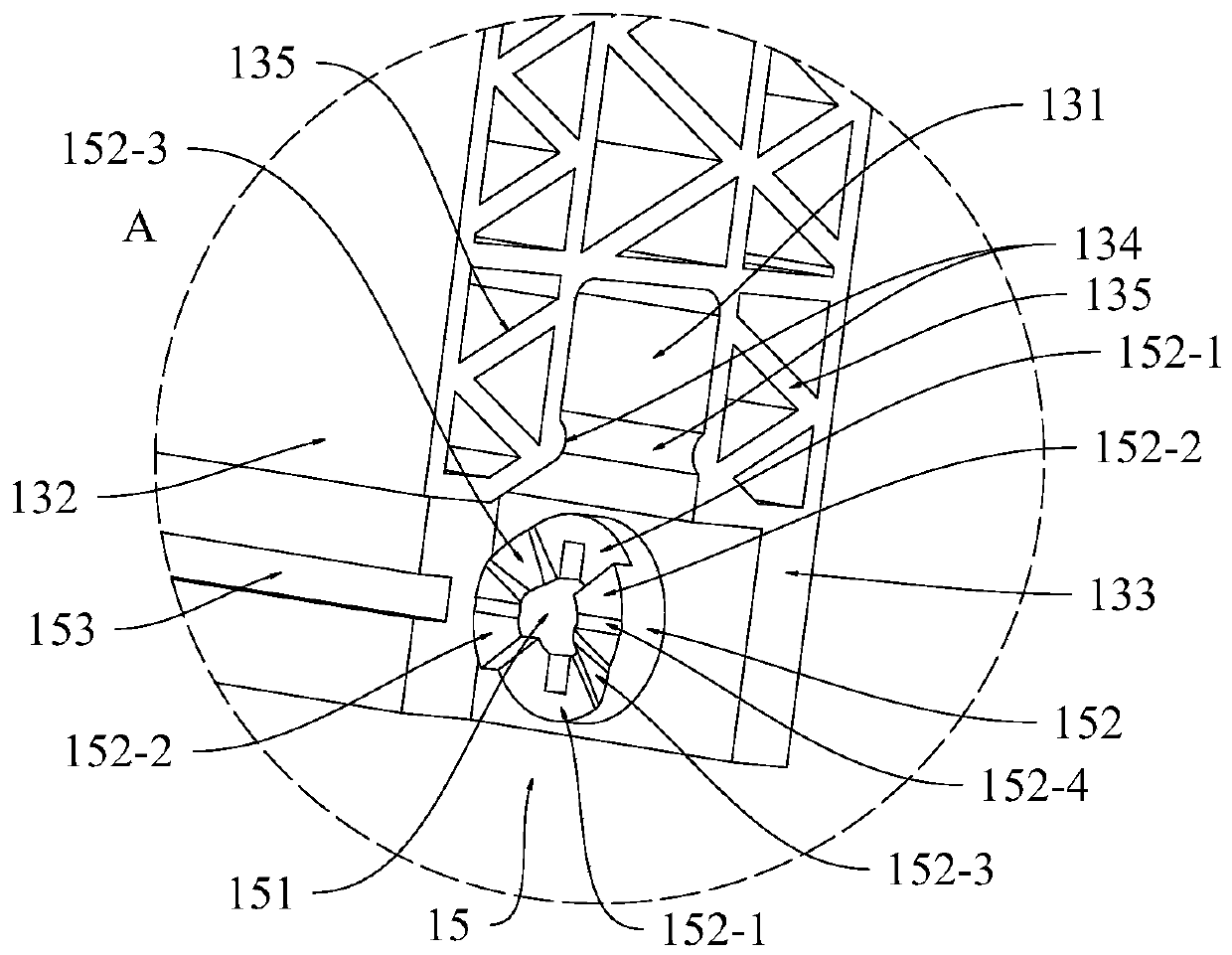

[0030] as attached figure 1 with attached figure 2 The shown prefabricated building wall panel 1 includes a panel body 11, and the panel body 11 has an odd number of cavities inside; wherein, the cavity at the central position has the largest width, and the other cavities have the largest width relative to the cavity at the central position. The cavity is arranged symmetrically, and the width of the cavity becomes smaller gradually when viewed from the center to both sides; each layer of cavity is provided with a first reinforcing rib 12, and each layer of cavity is divided into several layers by the first reinforcing rib 12 in it. Triangular area; looking from the middle of the panel body 11 to both sides, the distribution density of the first reinforcing ribs 12 in the cavity gradually increases from sparse to dense; The second clamping portion 14 ; the panel body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com