Huge amount interval adjusting method and huge amount transferring method and equipment of tiny electronic components

A technology of electronic components and adjustment methods, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of Micro-LED centrifugal dispersion deviation, difficulty in ensuring no adhesion, deviation of centrifugal dispersion results, etc., to achieve convenient function realization , Easy and precise decentralized control, low rate of out of control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

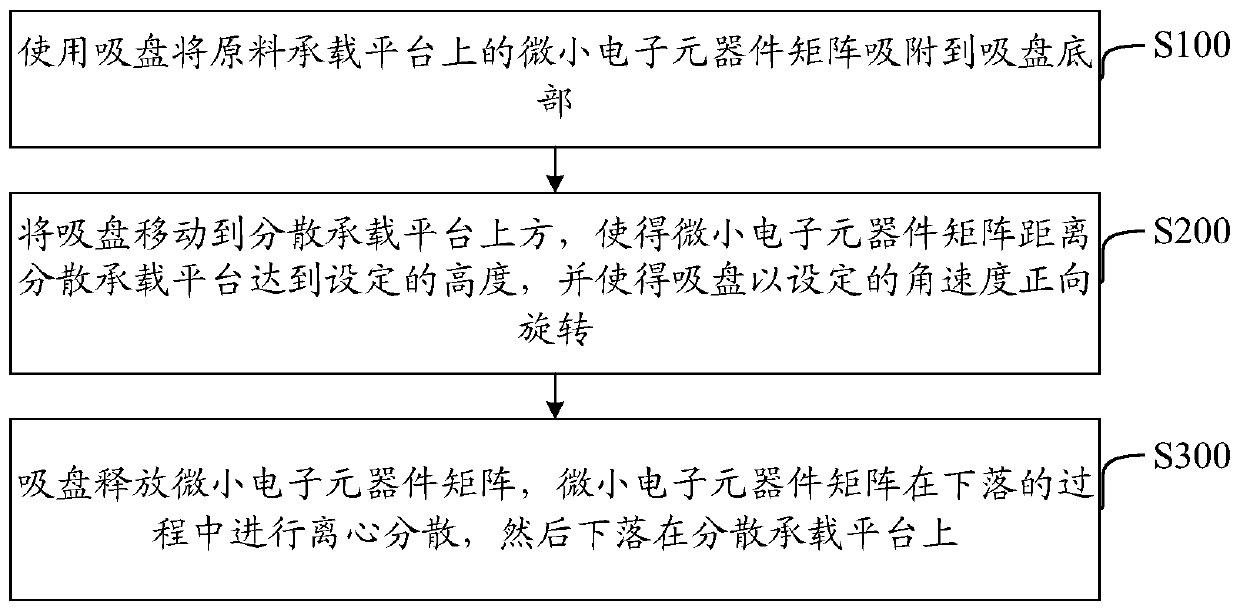

[0039] An embodiment of the present invention provides a method for adjusting a large amount of spacing between tiny electronic components, such as figure 1 As shown, the method includes:

[0040] Step S100: using a suction cup to absorb the array of tiny electronic components on the material carrying platform to the bottom of the suction cup.

[0041] Before the huge amount of pitch adjustment, the tiny electronic components are carried on the raw material carrying platform in an array. Taking Micro-LED as an example, Micro-LED chips are distributed on the wafer in an array, and the wafer is placed on the raw material carrying platform, and the array of Micro-LED chips on the wafer can be adsorbed by a suction cup.

[0042] The present invention does ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com