Tea packaging device

A technology for placing tea leaves and placing boards, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of easy drop and waste of tea leaves, and achieve the effects of reducing workload, avoiding waste, and avoiding manual transfer of tea leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

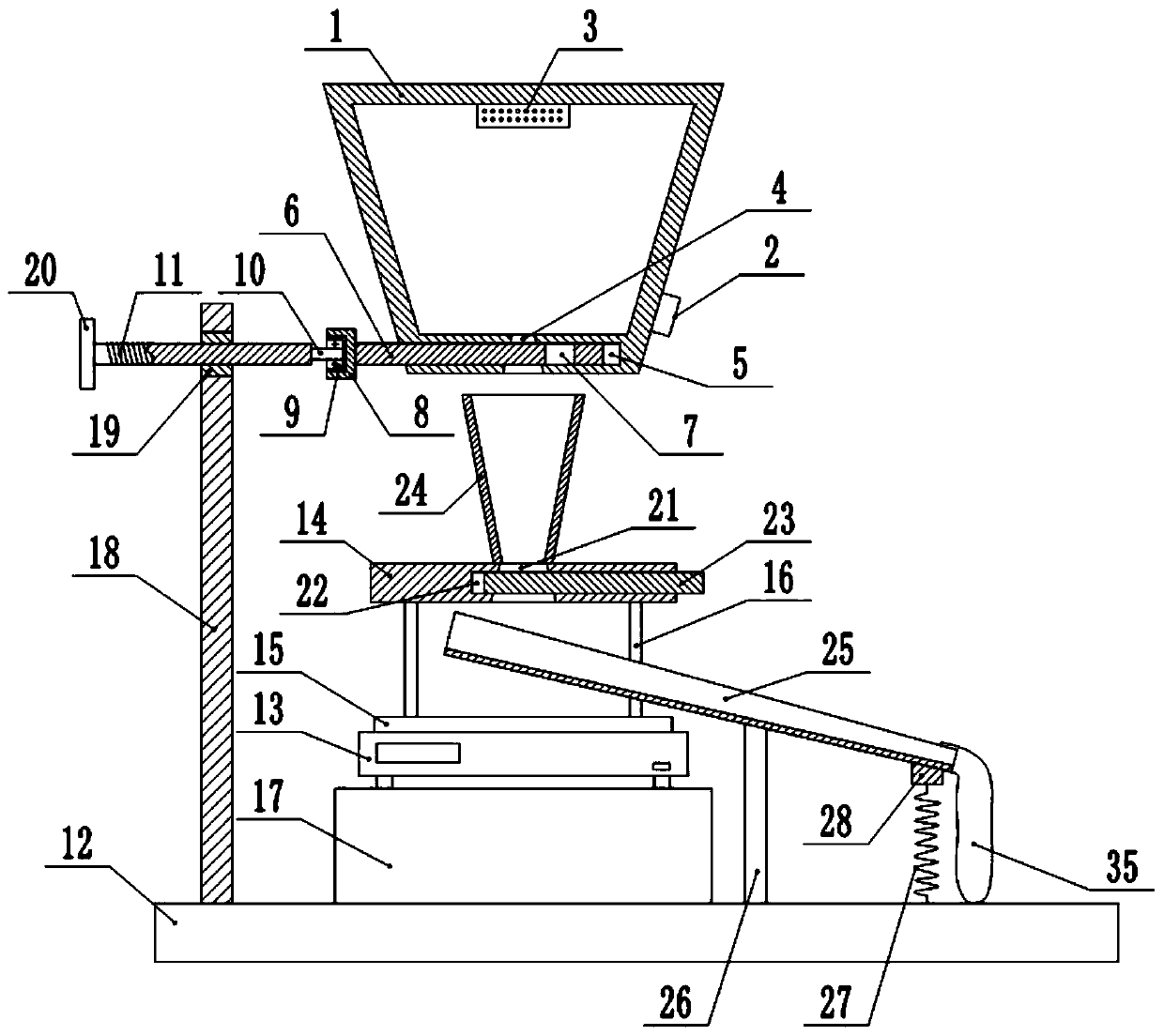

[0032] This embodiment is basically as figure 1 As shown: the tea packaging device includes a storage tank 1, and a vibrator 2 is fixedly installed on the side wall of the storage tank 1. In this embodiment, the model selected for the vibrator 2 is CZ10. The inner top wall of the storage tank 1 is fixedly connected with a drying chamber 3, and the side wall of the drying chamber 3 is provided with a number of ventilation holes, and the distance between adjacent ventilation holes is 20-30mm. The side wall of the drying chamber 3 is fixedly connected with an isolation net, and the isolation net covers all the ventilation holes to prevent the tea leaves from entering the drying chamber 3 . Several fiber desiccant sheets are placed in the drying chamber 3 .

[0033] The bottom wall of the storage tank 1 is provided with a discharge port 4 and a first cavity 5 arranged horizontally. A first sealing plate 6 is slidably connected to the first cavity 5. The first sealing plate 6 is p...

Embodiment 2

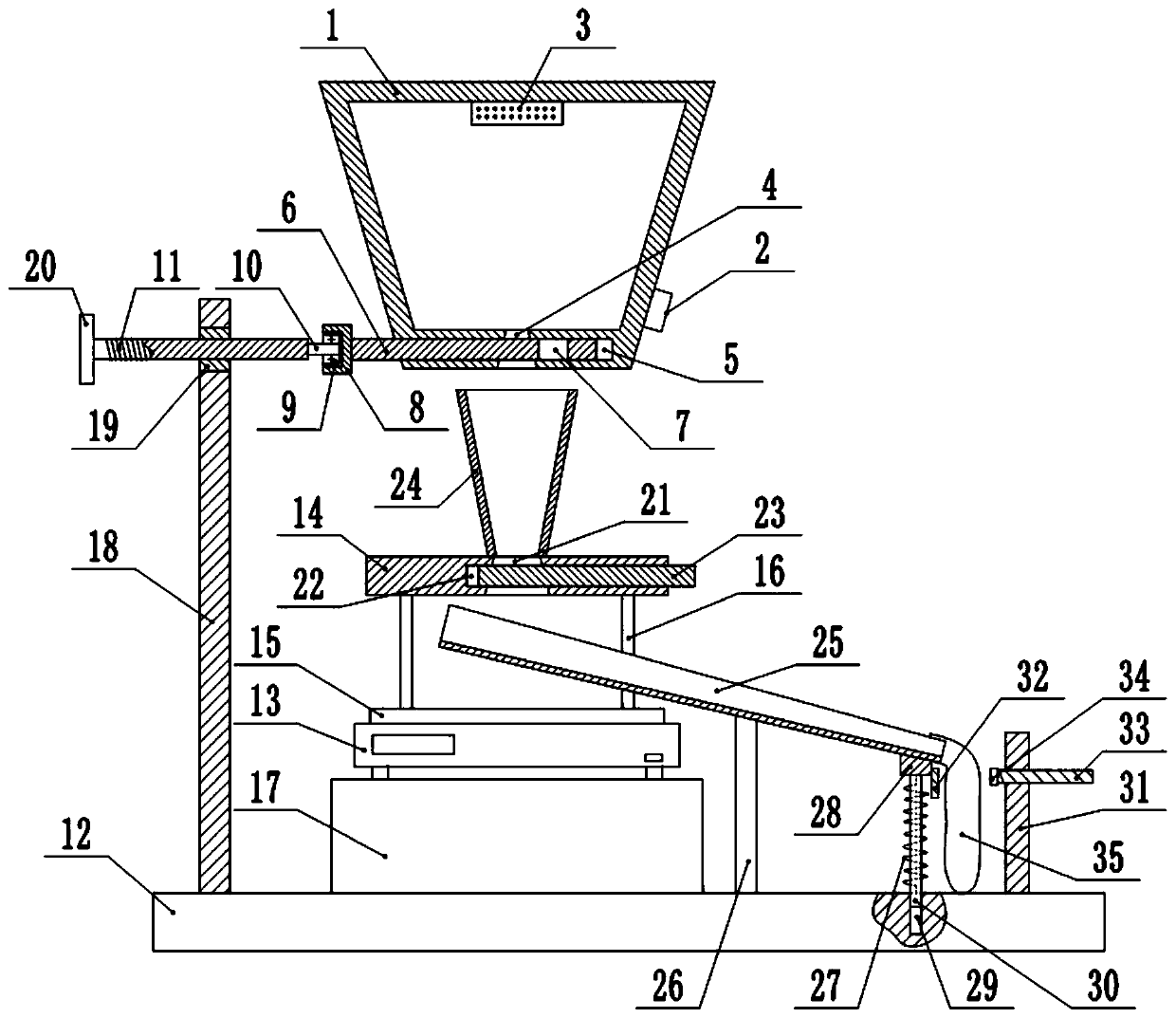

[0044] The difference between this embodiment and Embodiment 1 is that: figure 2 As shown, base 12 offers limit hole 29, and the bottom surface of pressing plate 28 is fixedly connected limit bar 30, and the bottom end of limit bar 30 stretches in limit hole 29, and the bottom end of limit bar 30 and limit hole 29 There is a gap between the bottom walls, that is, the limiting rod 30 can continue to extend into the limiting hole 29 . The base 12 is fixedly connected with a fixing plate 31 , the right side wall of the pressing plate 28 is fixedly connected with a sealing baffle 32 , and the far right end of the feeding plate 25 is located between the sealing baffle 32 and the fixing plate 31 . The fixed plate 31 is horizontally slidably connected with a moving rod 33 , specifically, the fixed plate 31 is provided with a hole through which the moving rod 33 passes. A heat sealing head 34 is fixedly connected to the left end of the moving rod 33 , and a switch for controlling th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com