All-in-one clamp automatic assembly line

An assembly line and clamp technology, applied in the field of multi-in-one clamp automatic assembly line, can solve the problems that affect the production efficiency of enterprises, equipment can only be idle, and labor intensity is high, and achieve the effect of compact structure, convenient maintenance and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

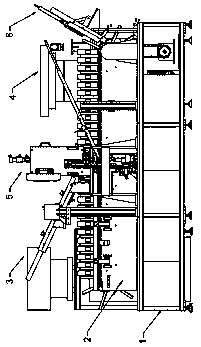

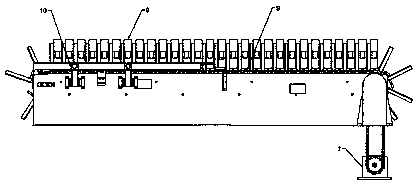

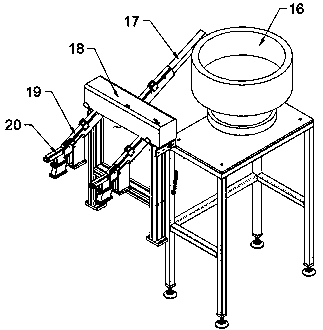

[0029] see Figure 1-8 , in an embodiment of the present invention, an all-in-one clamp automatic assembly line includes a frame 1, a conveyor line tooling 2, a bolt feeding mechanism 3, a nut feeding mechanism 4 and an assembly mechanism 5; Conveyor line tooling 2 is provided, and the conveyor line tooling 2 includes a conveyor belt 8 on which clamping plates 9 are equidistantly distributed, and clamping chambers for placing clamps are formed between the clamping plates 9, and the frame 1 There is an uprighting frame 10 on the top for straightening the hoops. The uprighting frame 10 mainly includes a set of limit plates set opposite to each other. The height and width of the uprighting frame 10 can be adjusted to adapt to the processing and transportation of hoops of different specifications. ; The transmission belt 8 is connected with a pulley, and the pulley is connected with a stepper motor 7 through a transmission chain to control the feeding speed of the clamp.

[0030]...

Embodiment 2

[0036]The difference between this embodiment and Embodiment 1 is that: the end of the conveying line tooling 2 is provided with a blanking mechanism 6, and the blanking mechanism 6 includes an adjusting channel plate 32 arranged opposite to the transmission belt 8, and the adjusting channel plate 32 is provided with an opening , the rear side of the opening is fixedly connected with a discharge plate 33, the front end of the adjustment channel plate 32 is abutted with a hoop lifting device 31, the hoop lifting device 31 is slidingly connected with the adjustment material channel plate 32, and the upper end of the hoop hoisting device 31 is connected There is a lifting cylinder 30; specifically, when the assembled clamp moves to the end of the conveyor belt 8, it falls into the clamp lifting device 31, driven by the lifting cylinder 30, the clamp is lifted to the opening and discharged from the discharge Plate 33 place slides out, completes blanking, avoids clip hoop to damage. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com