Automatic machining equipment for intelligent socket

A technology for processing equipment and smart sockets, applied in the field of automated processing equipment for smart sockets, can solve problems such as assembly difficulties, affecting socket processing efficiency, and damaging snap-on structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

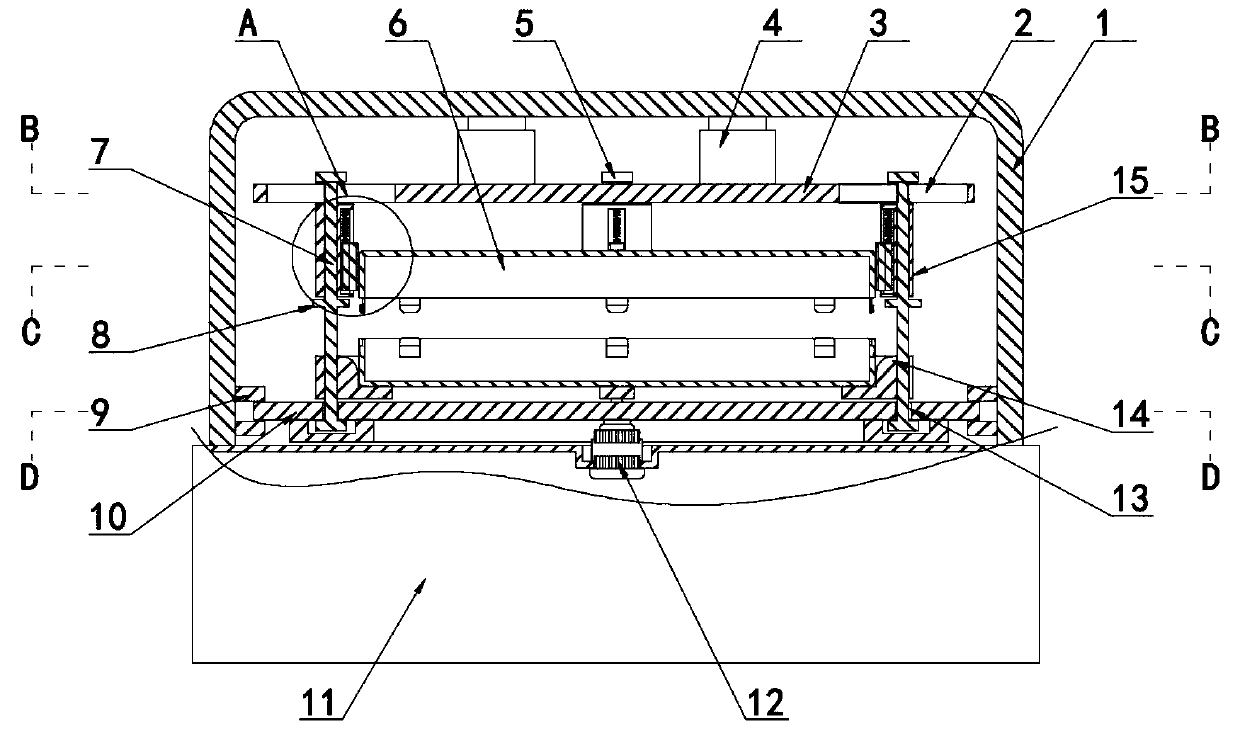

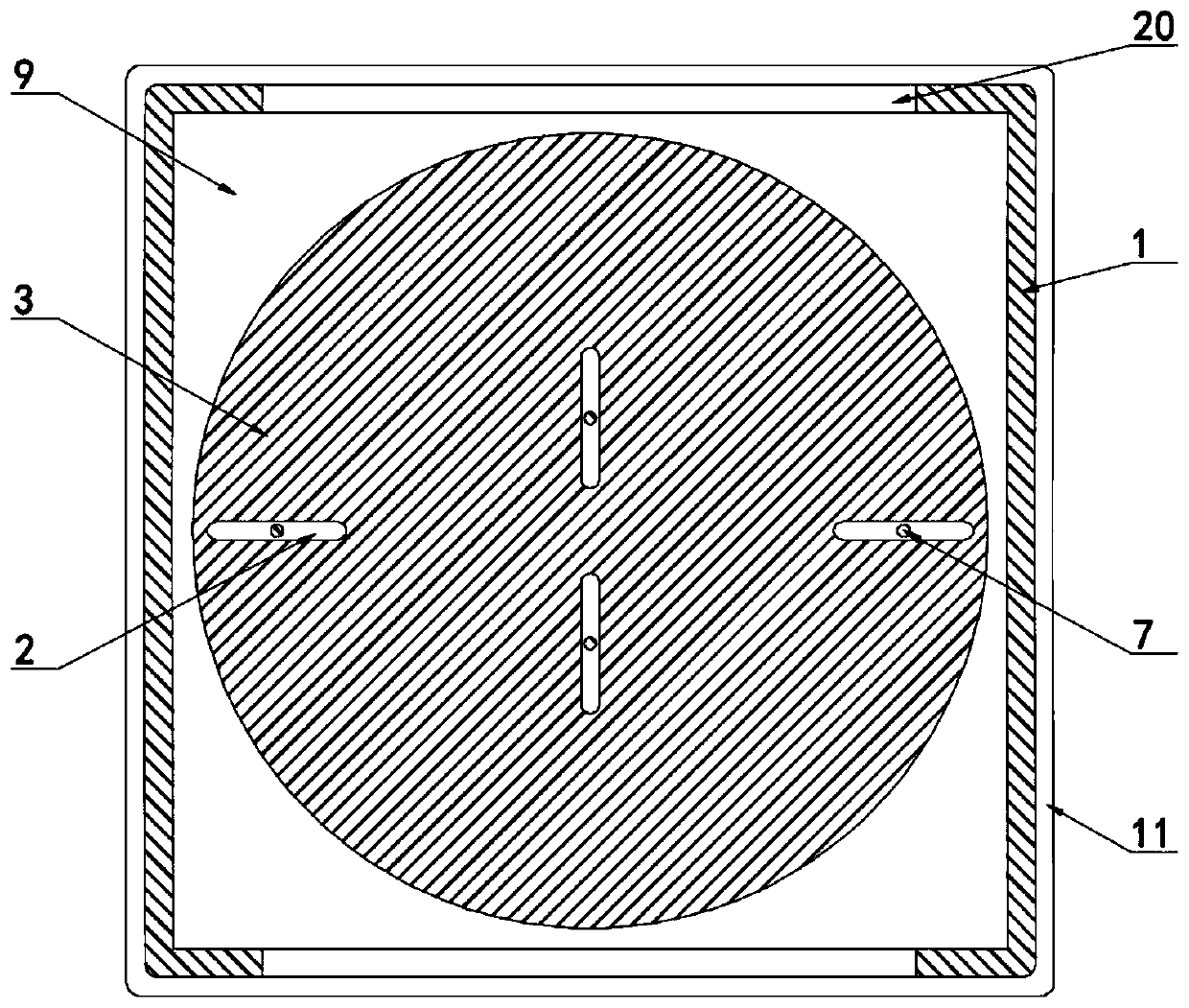

[0027] Embodiment one, with reference to Figure 1-5 , an automatic processing equipment for intelligent sockets, including a base 11 and a bracket 1 set on the base 11, an electric telescopic rod 4 is fixedly connected to the lower end surface of the top of the bracket 1, two socket housings 6 are arranged inside the bracket 1, and the base 11 A driving motor 12 is fixedly connected to the center of the end face, a turning slot 9 is provided on the inner side of the bottom of the support 1, and a second horizontal plate 10 is connected to the inside of the turning slot 9, and a first horizontal plate 3 is fixedly connected to the lower end surface of the electric telescopic rod 4, and The first horizontal plate 3 is provided with four first chute 2, and the inside of the four first chute 2 is slidably connected with a slide bar 7, and the second horizontal plate 10 is provided with a second chute 13, and the second chute 2 The groove 13 is slidingly connected with the slide b...

Embodiment 2

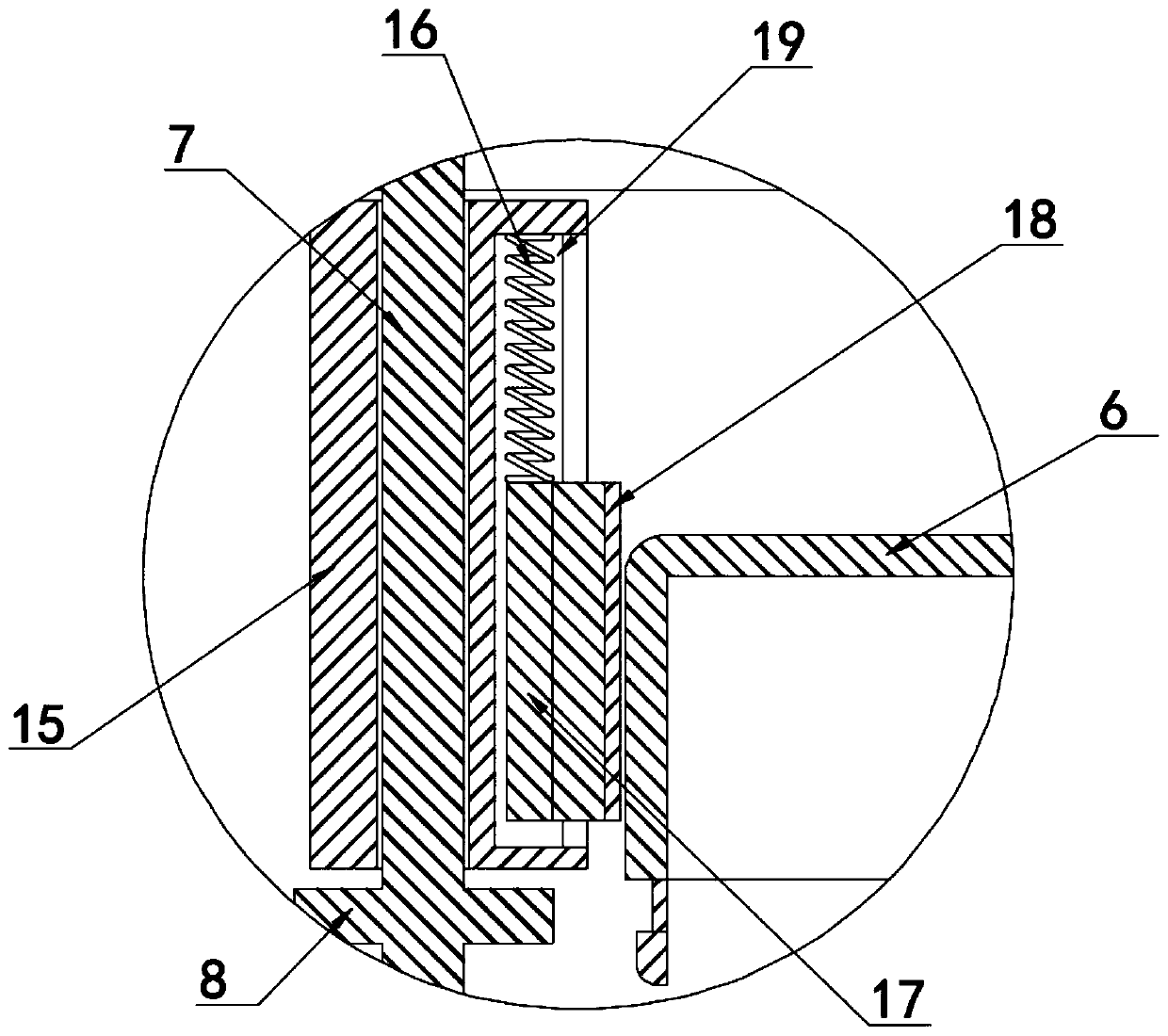

[0028] Embodiment two, refer to figure 1 and 2 , the top of the slide bar 7 is fixedly connected to the limit block 5, and the lower end surface of the limit block 5 is attached to the upper end surface of the first horizontal plate 3, and the side of the slide bar 7 is fixedly connected with a snap ring 8, and the snap ring 8 is connected to the sliding sleeve 15, the lower end surface is fitted and extruded so that the stopper 5 can limit the vertical direction of the slide bar 7, and at the same time, the snap ring 8 can limit the vertical direction of the sliding sleeve 15, so that the sliding sleeve 15 can hold the top The socket housing 6 is accurately aligned and fixed.

Embodiment 3

[0029] Embodiment three, refer to Figure 1-5 , the first chute 2, the slide bar 7 and the second chute 13 are all provided with four, and the four first chute 2 are all in a linear structure, and the adjacent two of the four first chute 2 The included angles are all 90°, and the four second chute 13 are in a semi-elliptical structure. One side of each sliding sleeve 15 close to the socket housing 6 is provided with a limit chute 19, the limit chute 19 and the limit slide 17 limit slide, and the limit slide 17 upper surface passes through the compression spring 16 and the limit slide. The bottom surface of the top of the groove 19 is elastically connected, so that the sliding bar 7 reciprocates close and far away under the joint action of the second sliding groove 13 and the first sliding groove 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com