Fracturing process for development and application of low permeability heterogeneous sandstone oil and gas reservoir

A technology for heterogeneous oil and gas formations, applied in the field of fracturing technology, can solve problems such as inability to achieve efficient development, failure to meet reservoir stimulation, and unsatisfactory effects, so as to improve the effect of fracturing stimulation, improve formation seepage field, and improve The effect of formation seepage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

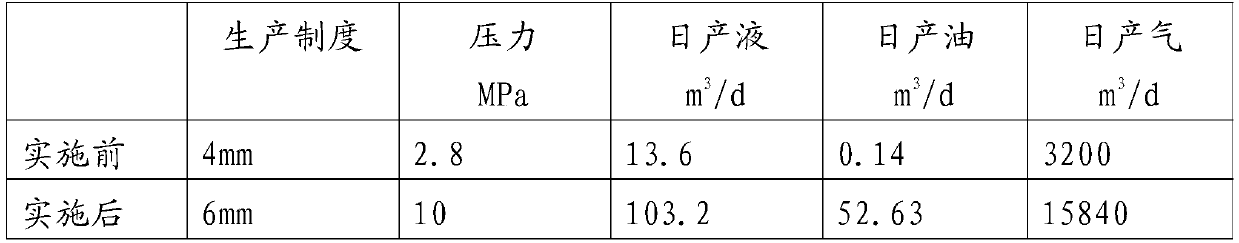

[0025] Example 1: Well A in the tidal sea area, the fracturing section is 4362.4m-4470.3m, and the well deviation is 63.2 0 . The span of the fracturing target layer is 107.9m, the perforated well section has 7 layers of 55.7m, and the logging interpretation permeability is 2.45×10 -3 μm 2 -23.63×10 -3 μm 2 , the effective permeability of well test interpretation is 1.1×10 -3 μm 2 , indicating that the formation has poor permeability. Optimizing the fracturing process design and implementing a total liquid volume of 4247m 3 , total sand volume 262m 3 , construction displacement 7m 3 / min. Among them, low-viscosity slick water accounts for 85%, 70 / 140 quartz sand accounts for 31%, and the remaining proppant is preferably ceramsite combined with 40 / 70 mesh and 30 / 50m mesh. Seawater-based slick water and seawater-based low-viscosity fracturing fluid are used for fracturing fluid, all of which are continuously mixed on site. The well implementation effect is remarkable....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com