A coal mine rockburst well up and down advanced pre-control method

A technology of ground pressure and coal mines, applied in mining equipment, earthwork drilling, mining equipment, etc., to achieve the effect of strong operability, convenient establishment and large control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

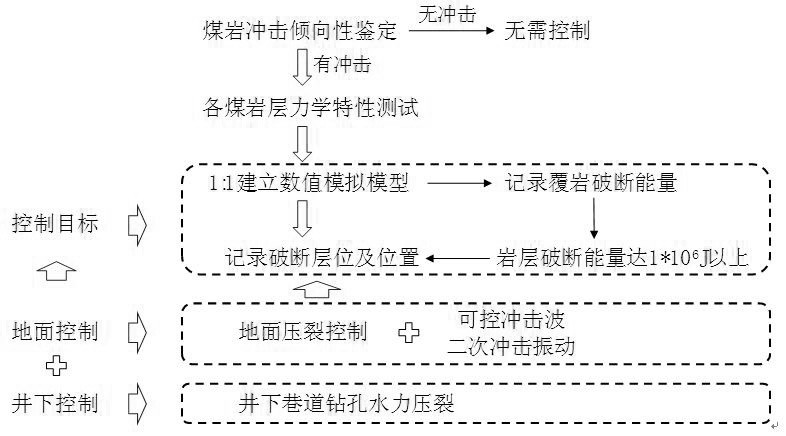

[0019] A coal mine rock burst well up and down advanced pre-control method includes the following steps.

[0020] S100~Before the mining of the coal seam, drill holes in the coal seam and its roof and floor to measure the impact tendency of the coal and rock mass, and divide the impact tendency into four grades: no impact, weak impact, impact and strong impact according to the measurement results .

[0021] S200~If the measurement result is no impact, no control is required; if the measurement result is weak impact or above, determine the impact strength and control technology according to the following steps.

[0022] S300~Drill vertical holes from the surface of the working face down to the coal seam, take the cores of each coal rock layer and measure their mechanical properties, and measure the compressive strength, tensile strength, compressive strength, bulk density, thickness, modulus of elasticity and Poisson's ratio.

[0023] S400~Establish a numerical simulation mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com