Form plate system of prefabricated U-shaped beam

A U-shaped, formwork technology, applied in the direction of manufacturing tools, ceramic forming machines, ceramic forming cores, etc., can solve the problems of difficulty in formwork adjustment, long installation and removal time, low work efficiency, etc., and achieve high construction efficiency and beautiful appearance , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below with reference to the accompanying drawings.

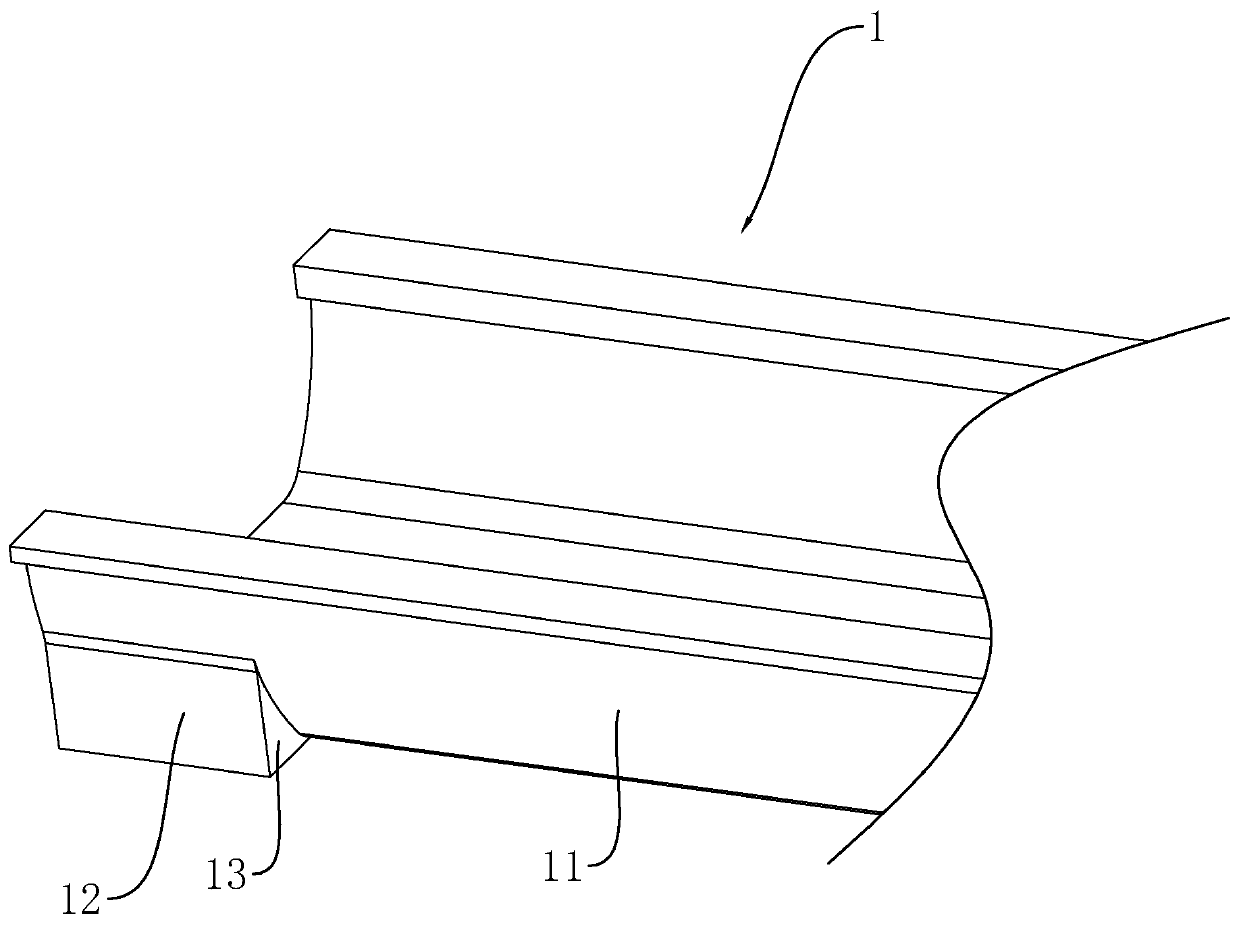

[0040] refer to figure 1 , because the lower structure of the middle section and the end section of the U-shaped beam 1 is different, the U-shaped beam 1 is divided into a middle section 11 and an end section 12, and a vertical transition surface is formed at the connection between the end section 12 and the middle section 11 13.

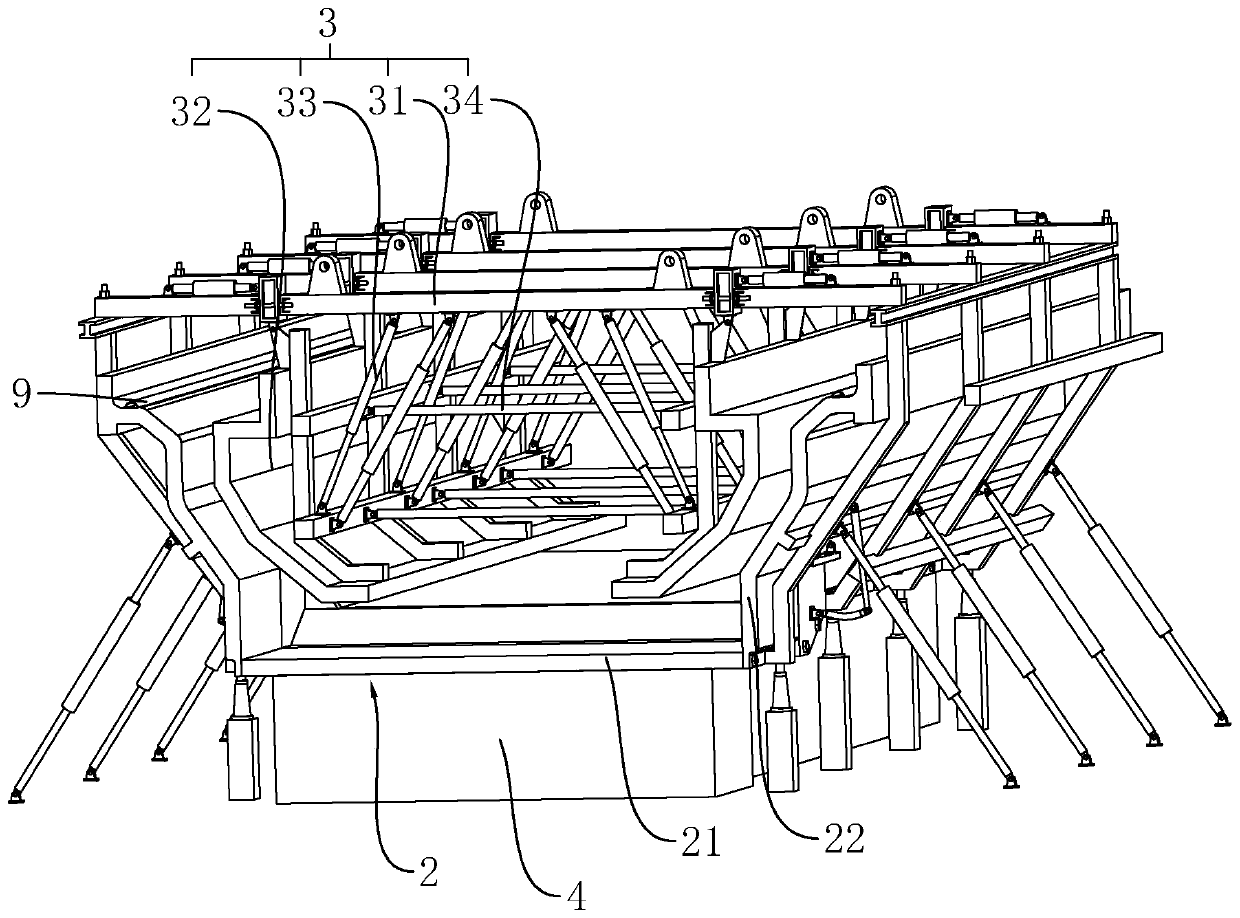

[0041] refer to figure 2 , the formwork system of the prefabricated U-shaped beam, including the outer mold unit 2, the inner mold unit 3 erected directly above the outer mold unit 2 and the end molds respectively arranged at both ends of the outer mold unit 2, the outer mold unit 2, the inner mold unit 3 and the end mold A cavity for casting the U-shaped beam 1 is formed between the molds.

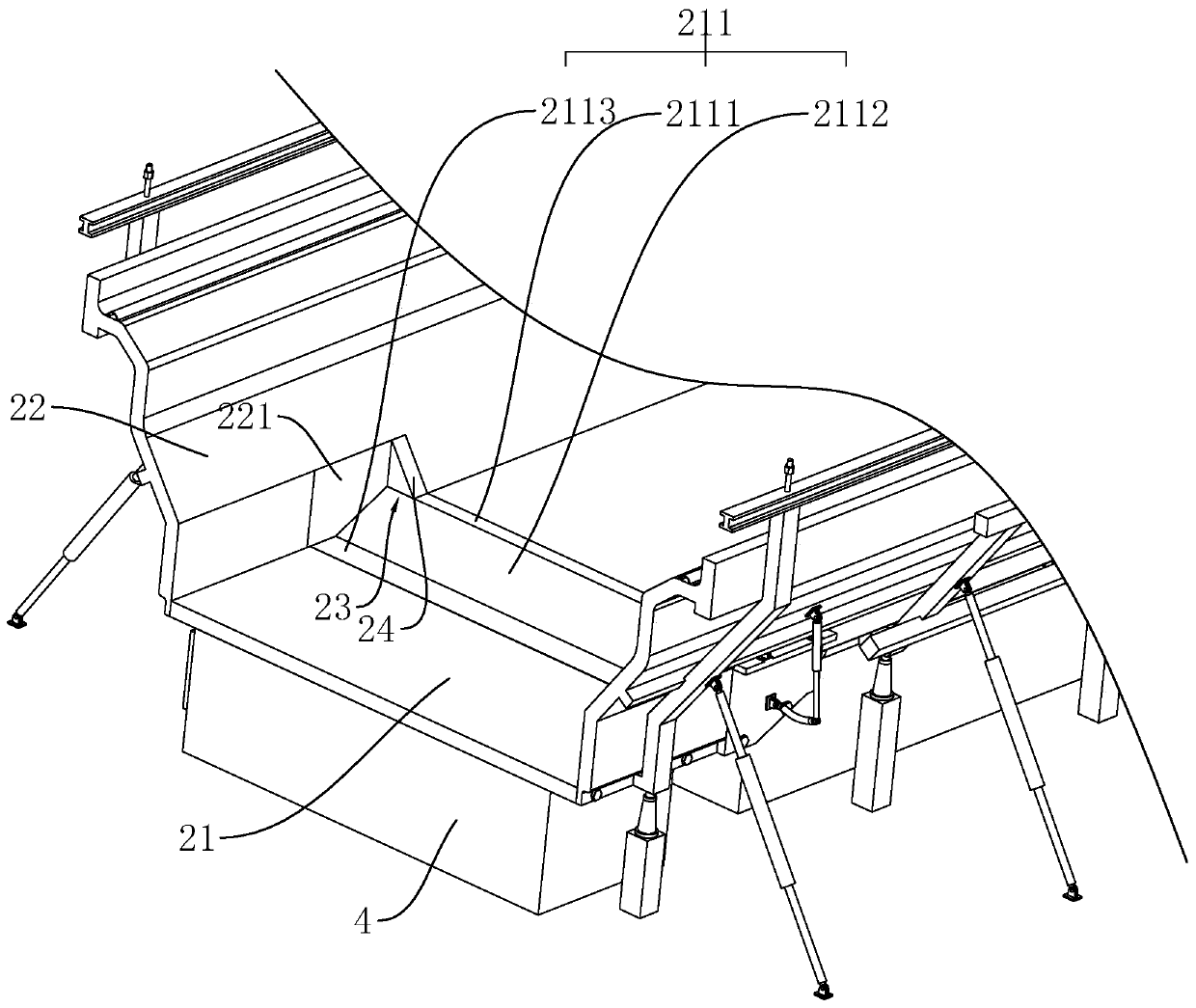

[0042] The outer mold unit 2 includes a bottom mold 21 and a side mold 22 . The bottom mold 21 is arranged on the base 4 , and the base 4 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com