Cable hook for coal mine

A cable hook, coal mine technology, used in mining devices, electrical components, mining equipment and other directions, can solve the problems of cable falling off, unfavorable cable replacement or maintenance, easy to entangle each other, etc., to avoid the effect of cable separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below.

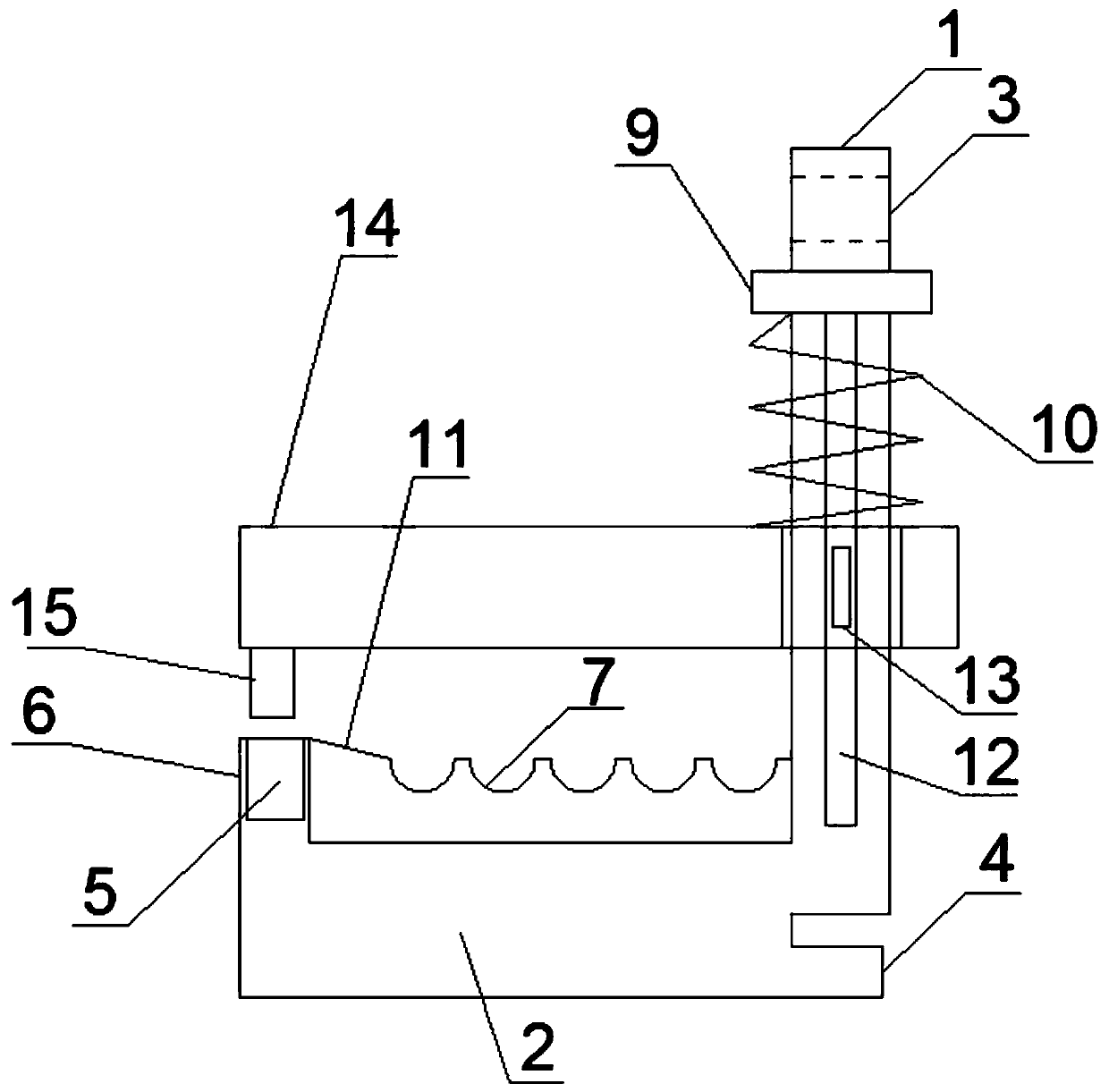

[0015] Such as figure 1 As shown, a cable hook used in coal mines includes an L-shaped component body, and the component body includes a vertically arranged long arm 1 and a short arm 2 fixedly connected to the left side of the lower end of the long arm 1 transversely. The upper end of the arm 1 is provided with a hanging hole 3, and the lower end of the right side of the short arm 2 is provided with a hanging rod 4 matched with the hanging hole 3, and also includes a pressing plate 14; the left end of the short arm 2 is fixedly connected with a Limiting block 6, the upper part of limiting block 6 is provided with positioning groove 5, and short arm 2 is equipped with shock-absorbing pad 8 in the part beyond limiting block 6, and shock-absorbing pad 8 is evenly provided with a plurality of along its length direction. Groove 7;

[0016] The long arm 1 is provided with a limiting ring 9 at the bottom of the hangin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com