A contact piece anti-return connector

A technology of contacts and connectors, which is applied in the direction of vehicle connectors, connections, parts of connection devices, etc., can solve problems such as breakage, increased contact resistance of connectors, and prolapse of contacts, and achieves an effective and reliable anti-retraction method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

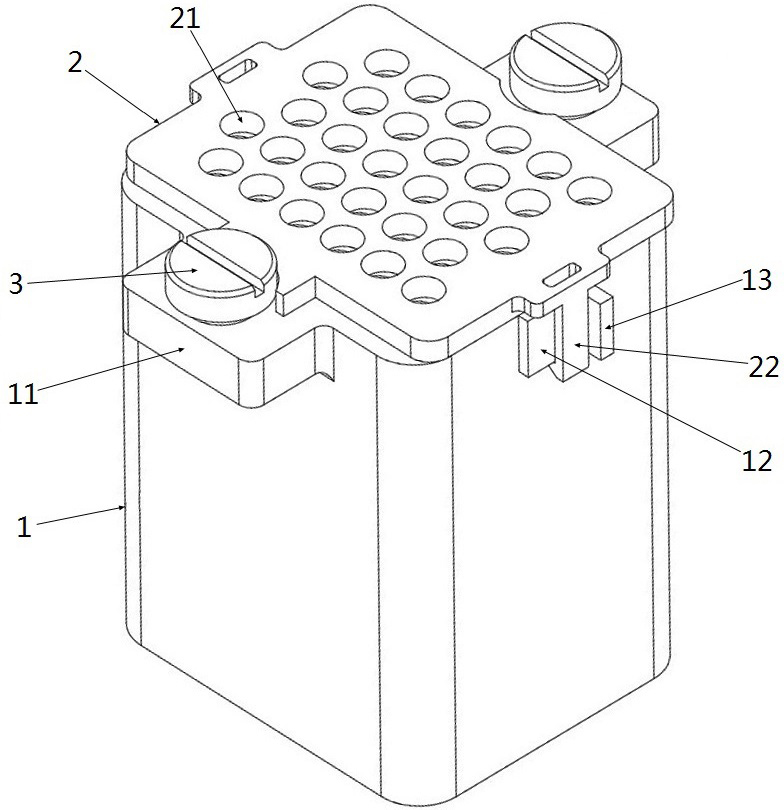

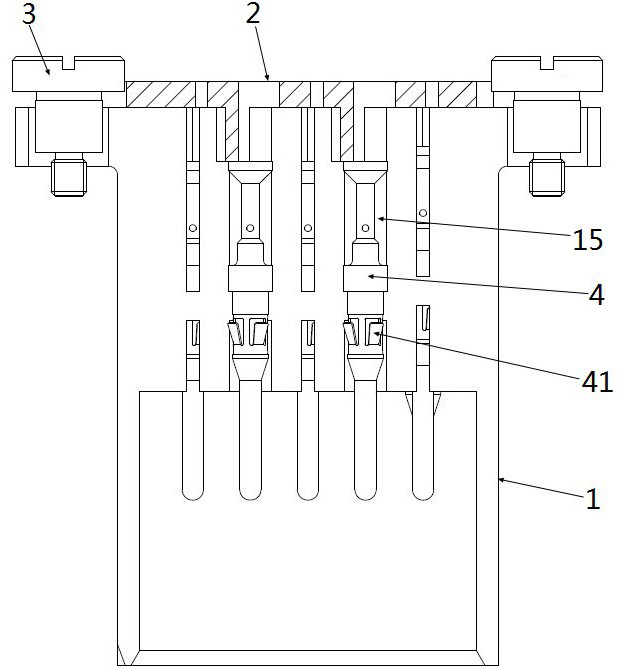

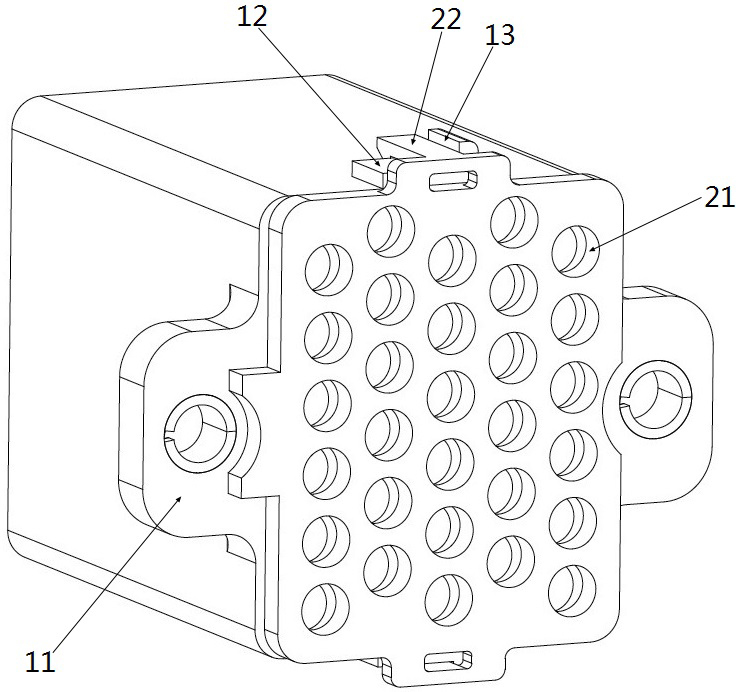

[0028] An embodiment of the anti-retraction connector of the contact piece in the present invention is as follows Figure 1~Figure 2 As shown, it includes a housing 1 and a baffle 2 connected to the housing 1, combined with Figure 5 As shown, the housing 1 is provided with a plurality of contact installation holes 15 , and the contacts 4 are installed in the contact installation holes 15 . The structure of the contact piece 4 is as figure 2 , Figure 6 as well as Figure 8 As shown, the front end of contact 4 ( Figure 8 The left end in the middle) is the plug end, the rear end ( Figure 8 The right end in the middle) is the wire outlet end, and the wire outlet end is provided with an outlet hole 42. In addition, the middle part of the contact piece 4 is provided with a claw 41, and a positioning stepped surface is provided in the mounting hole 15 of the contact piece to match the positioning of the claw 41. During the installation of the contact piece 4, the claw 41 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com