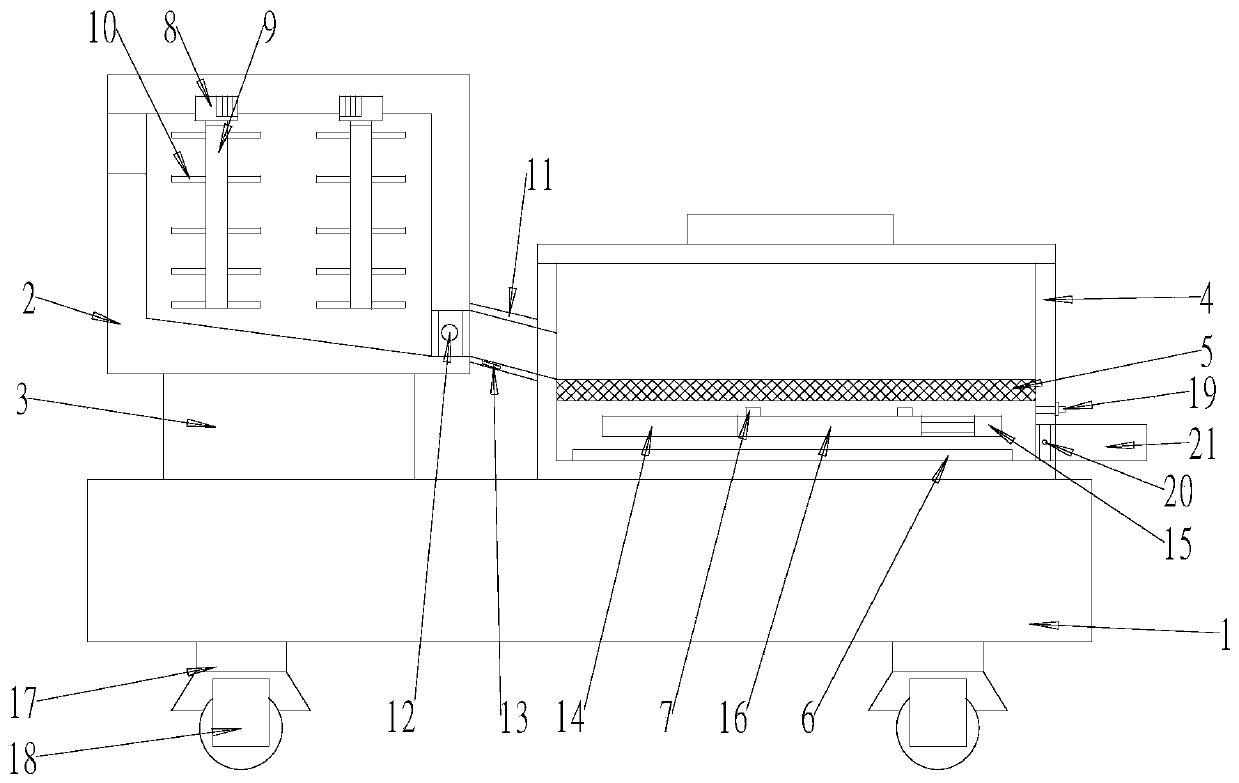

Board waste harmless treatment system for printing

A harmless treatment and waste technology, applied in grain treatment, incinerators, indirect carbon dioxide emission reduction, etc., to achieve low cost, reduce environmental pollution, and new structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

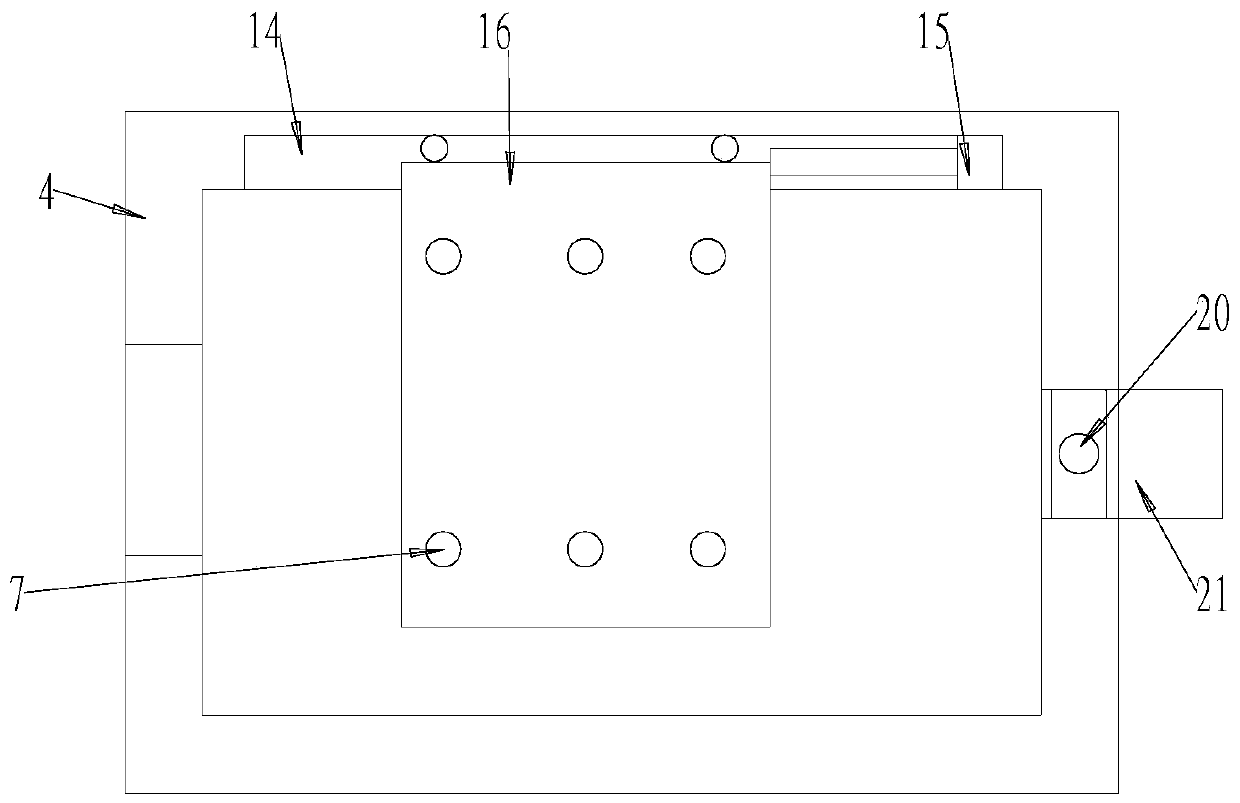

[0029] First, the console 1 is moved through the universal wheels 17. When moving to the designated work place, the universal wheels 17 can be fixed through the brake pads 18 to avoid shaking during work, and then the waste can be put into the to the inside of the crushing chamber 2, and then the rotating rod 9 is driven by the rotating motor 8 to rotate, so that the rotating rod 9 drives the crushing cutter head 10 to rotate at a high speed, and the waste can be crushed during the rotation. When the crushing is completed, it can be passed The discharge port enters the conveying pipeline 11, and by opening the valve 12 in the conveying pipeline 11, the crushed waste enters the incineration chamber 4 from the conveying slide, and the buzzer 13 allows the waste to enter the incineration chamber 4. Inside, the gun nozzle 7 in the incineration chamber 4 will move with the sliding trolley 16, thereby ejecting flames to achieve the function of incineration, and then the external conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com