A Steel Plate Concrete Shear Wall Convenient for Space Limitation

A steel plate concrete and shear wall technology, applied to walls, buildings, building components, etc., can solve problems such as inaccurate data, failure to obtain experimental data, and falling of shear walls, achieving high safety, accurate experimental data, The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

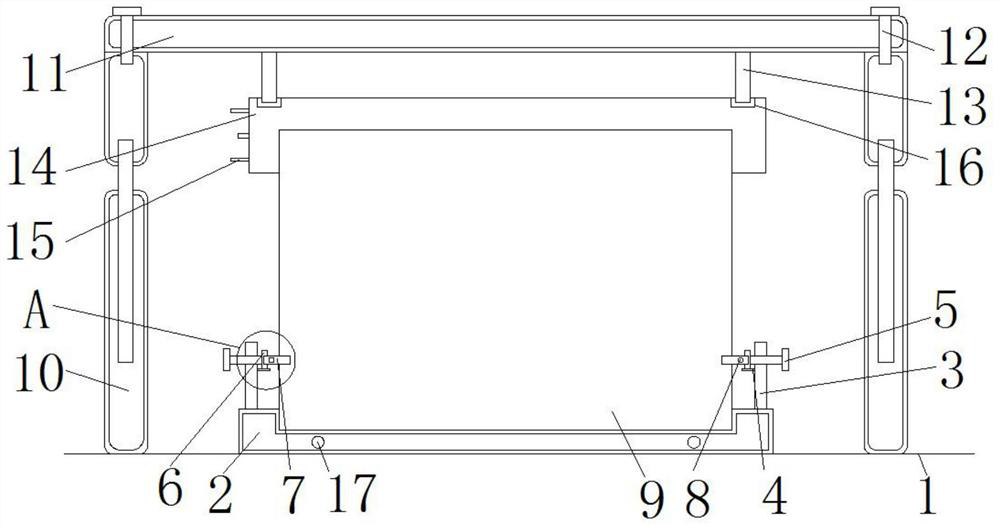

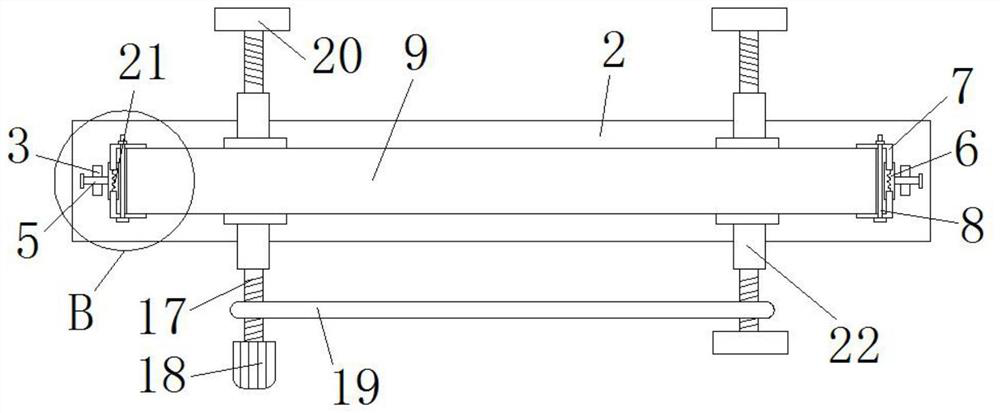

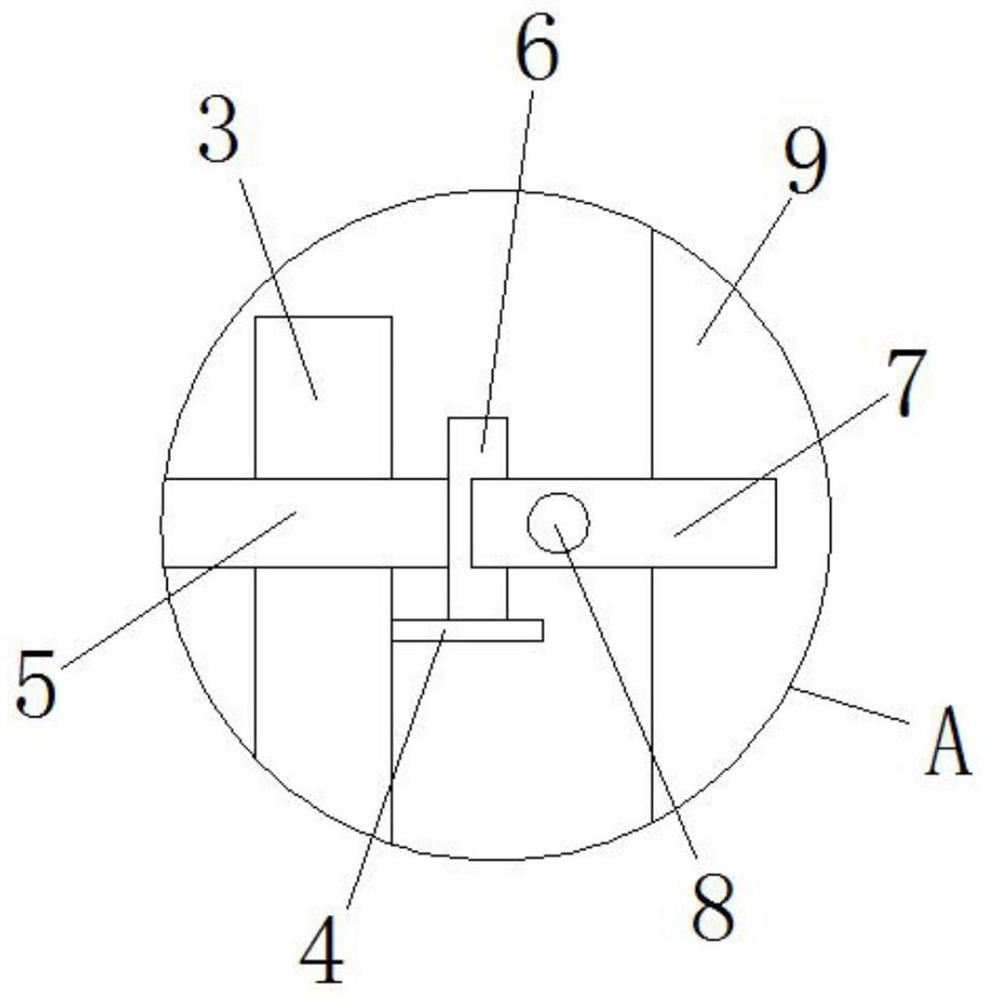

[0024] from Figure 1-5 It can be seen that a steel plate concrete shear wall convenient for positioning in this embodiment includes a base 2 and a shear wall body 9, the bottom of the base 2 is the ground 1, the bottom of the base 2 is attached to the ground 1, and the bottom of the base 2 The upper surface is fixed with a support rod 3, the side of the support rod 3 is fixed with a limit rod 4, the surface of the support rod 3 is equipped with a rotating rod 5, the surface of the rotating rod 5 is fixed with a fixed block 6, and the surface of the fixed block 6 is provided with a stabilizing plate 7. The surface of the stabilizing plate 7 is welded with a spring 21, the surface of the stabilizing plate 7 is installed with a tightening bolt 8, the upper surface of the base 2 is provided with a shear wall body 9, and the upper surface of the shear wall body 9 is equipped with a clamping block 14 , the surface of the block 14 is provided with grooves 16, the two sides of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com