Suction nozzle mounting instrument for soft packaging bag

A technology for flexible packaging bags and instruments, which is applied in the field of suction nozzle installation instruments, can solve the problems of low success rate, production efficiency, waste of raw materials, etc., and achieve the effect of high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

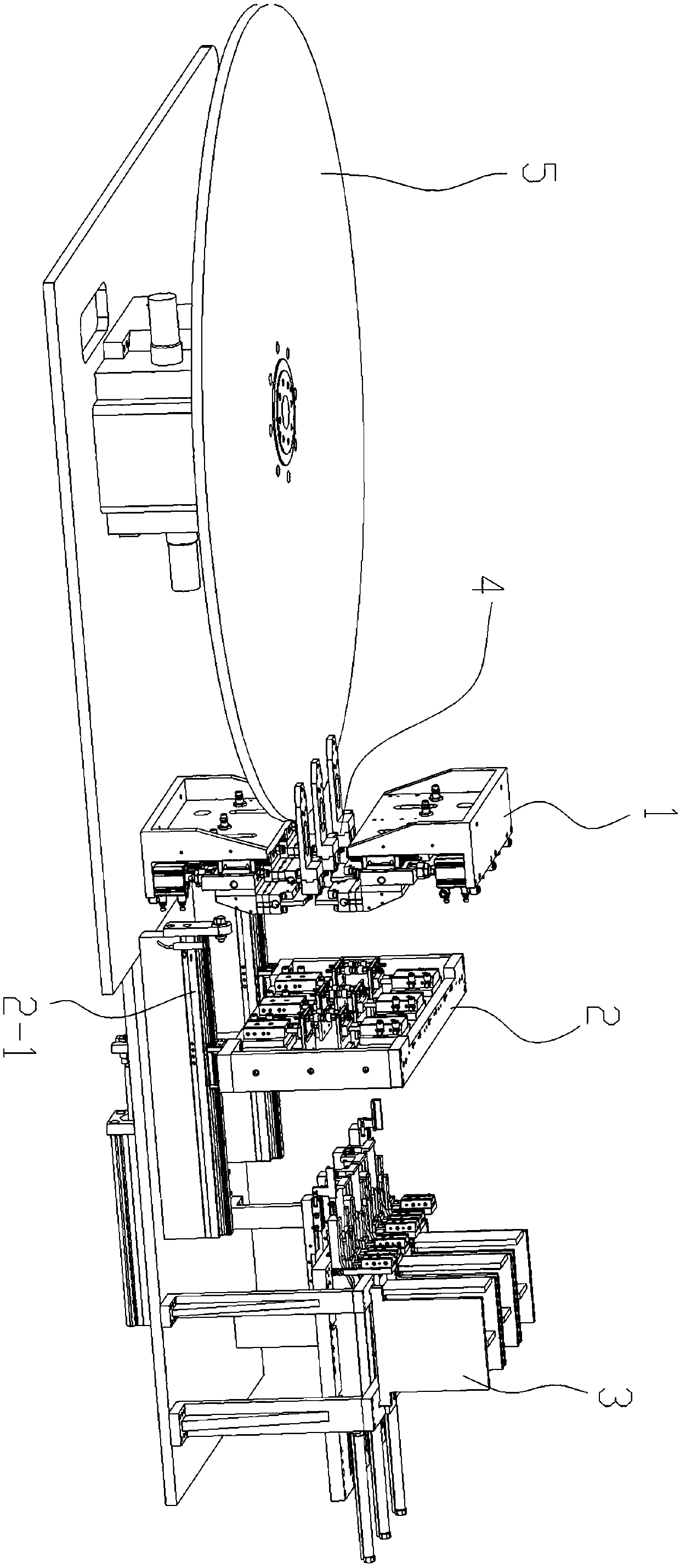

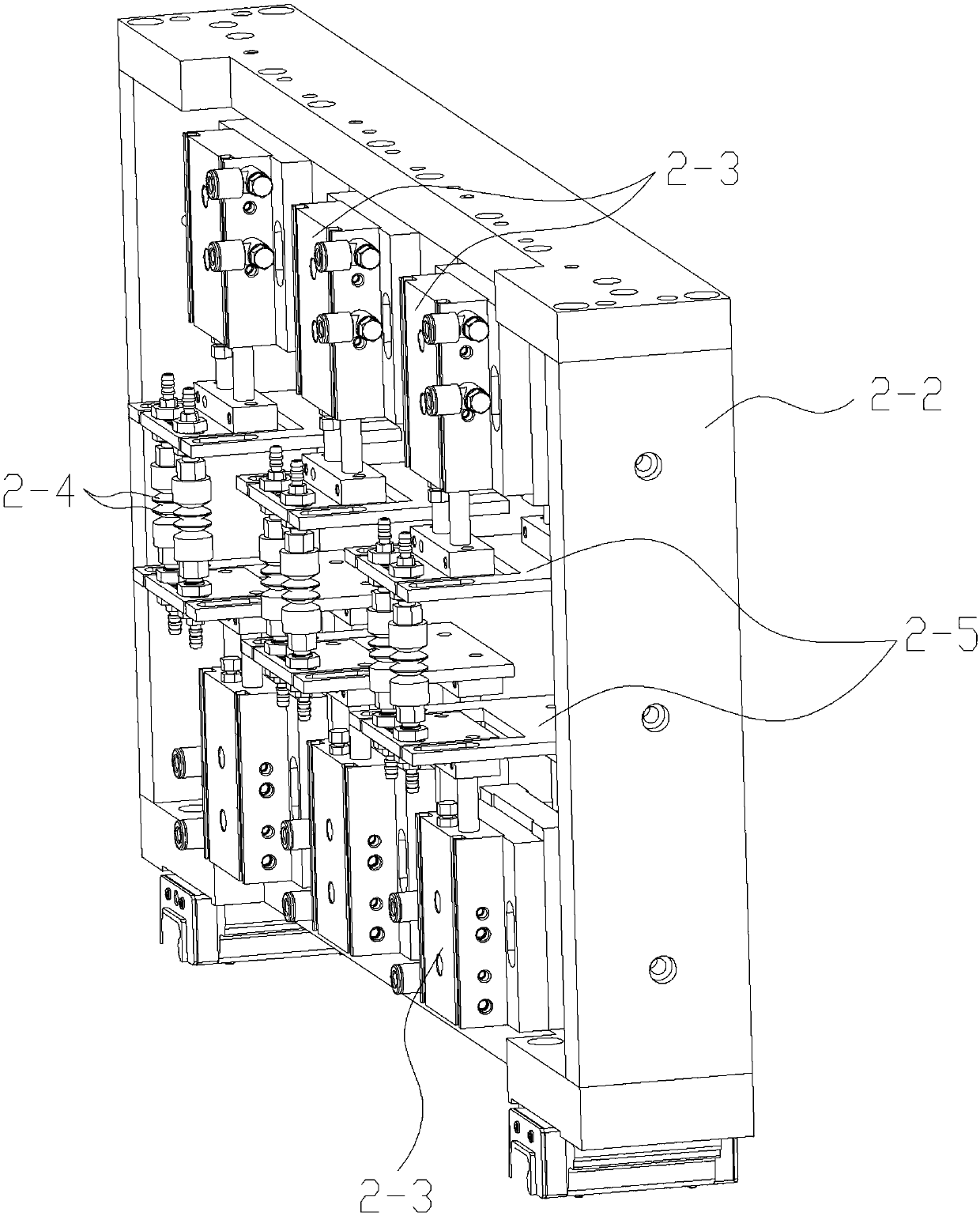

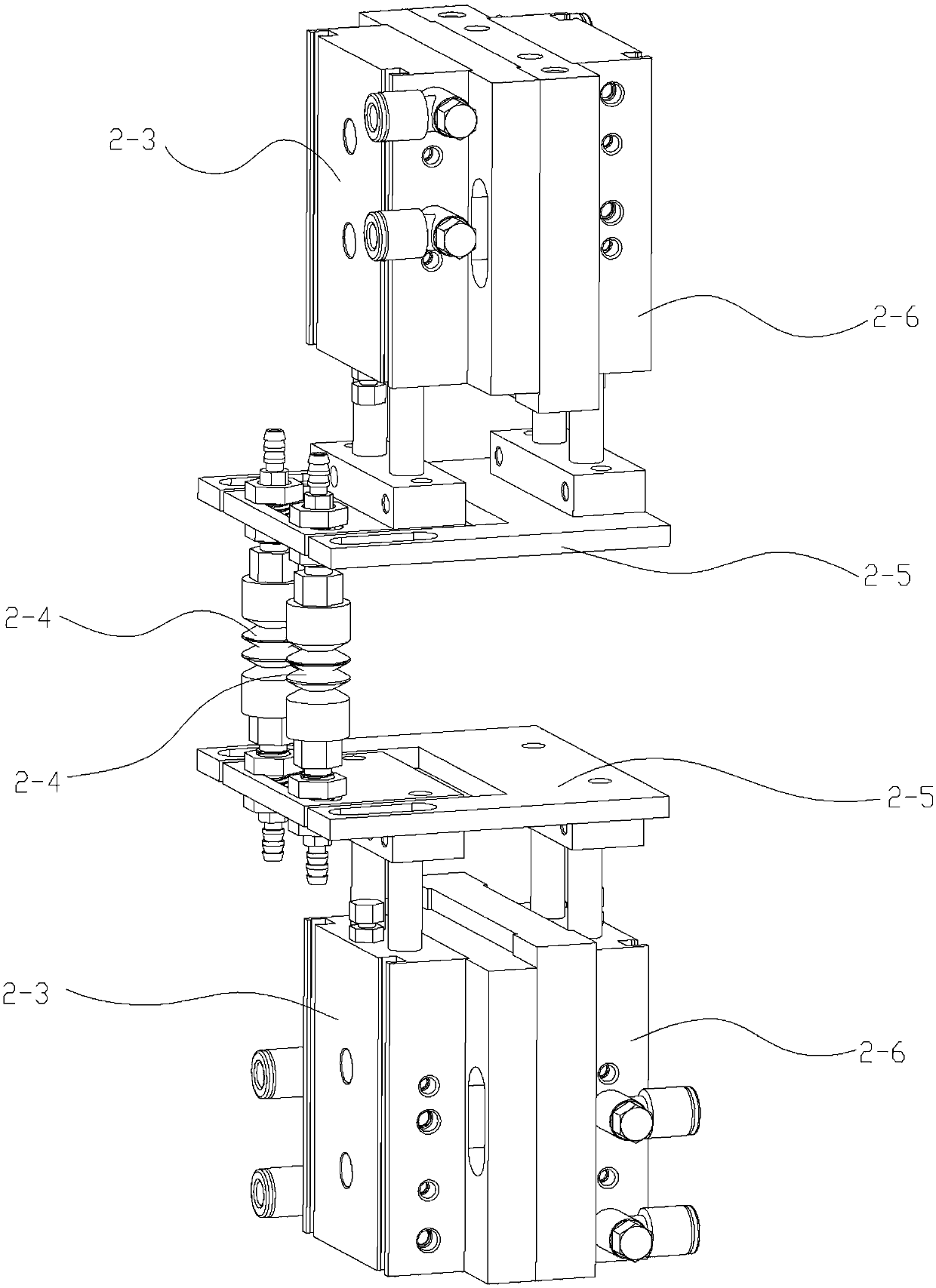

[0012] See attached figure 1 , 2 And 3. The nozzle installation device for the flexible packaging bag of this embodiment includes a flexible packaging bag feeding device 3, a flexible packaging bag opening device 2 for opening the opening of the flexible packaging bag to which the flexible packaging bag feeding device 3 is sent Place the suction nozzle at the opening of the flexible packaging bag, the mouth-up device 4, and the edge sealing device 1 for sealing the suction nozzle and the opening of the flexible packaging bag, the flexible packaging bag opening device 2 includes a frame 2-2, a composition The sucker 2-4 and the sucker drive mechanism 2-3 are arranged oppositely, the sucker drive mechanism 2-3 is installed on the frame 2-2, and the sucker drive mechanism 2-3 is used to drive the pair of suckers 2-4 Moving toward or in the opposite direction, the flexible packaging bag feeding device 3 is used to feed the flexible packaging bag between the pair of suction cups 2-4....

Embodiment 2

[0015] Compared with embodiment 1, the nozzle installation device for the flexible packaging bag of this embodiment also includes a set of baffles 2-5, and the baffle 2-5 is fixedly connected to the frame 2-2 and Correspondingly arranged on the movement path of the suction cup 2-4, the baffle 2-5 is preferably a "C" shape and half-encloses the movement path of the suction cup 2-4, and the opening direction of the "C" shape points to the upper nozzle device 4. The area enclosed by 2-5 is larger than the size of the suction cup 2-4 and smaller than the size of the flexible packaging bag, so that the suction cup 2-4 can pass through the area enclosed by the baffle 2-5, but when the suction cup 2-4 passes, the suction cup 2-4 The adsorbed flexible packaging bag is blocked, so that the suction cup 2-4 is separated from the flexible packaging bag.

Embodiment 3

[0017] Compared with Embodiment 2, this embodiment also includes a baffle cylinder 2-6. The baffle 2-5 is not fixed on the frame 2-2, but is fixedly connected to the output end of the baffle cylinder 2-6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com