Insulated wire, and wire harness

A technology of insulated wires and wires, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve the limited effect of improving wear resistance, difficulty in achieving flexibility and wear resistance at the same time, and difficulty in fully ensuring the insulation coating Softness and other issues, to achieve high wear resistance, excellent softness effect

Inactive Publication Date: 2020-02-07

AUTONETWORKS TECH LTD +2

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the effect of improving the wear resistance due to the addition of these resin components to the PVC resin is limited, and even if the wear resistance is improved, it is difficult to sufficiently ensure the flexibility of the insulating coating layer, and it is difficult to achieve both. Softness and abrasion resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0066] Examples of the present invention are shown below. It should be noted that the present invention is not limited by these examples.

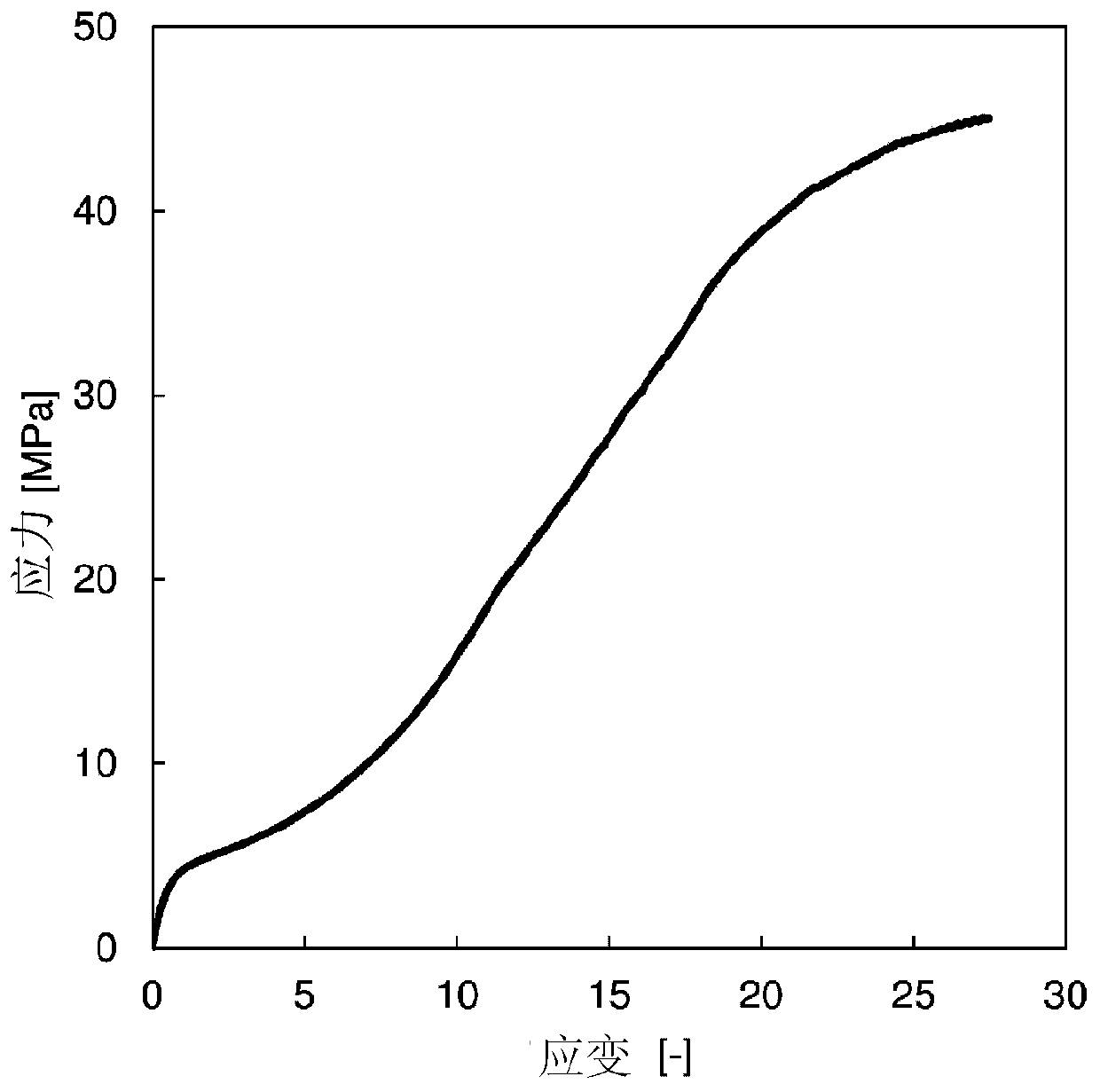

[0067] [Test A: Characteristics of insulating covering layer mainly composed of thermoplastic polyurethane elastomer]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to view more

Abstract

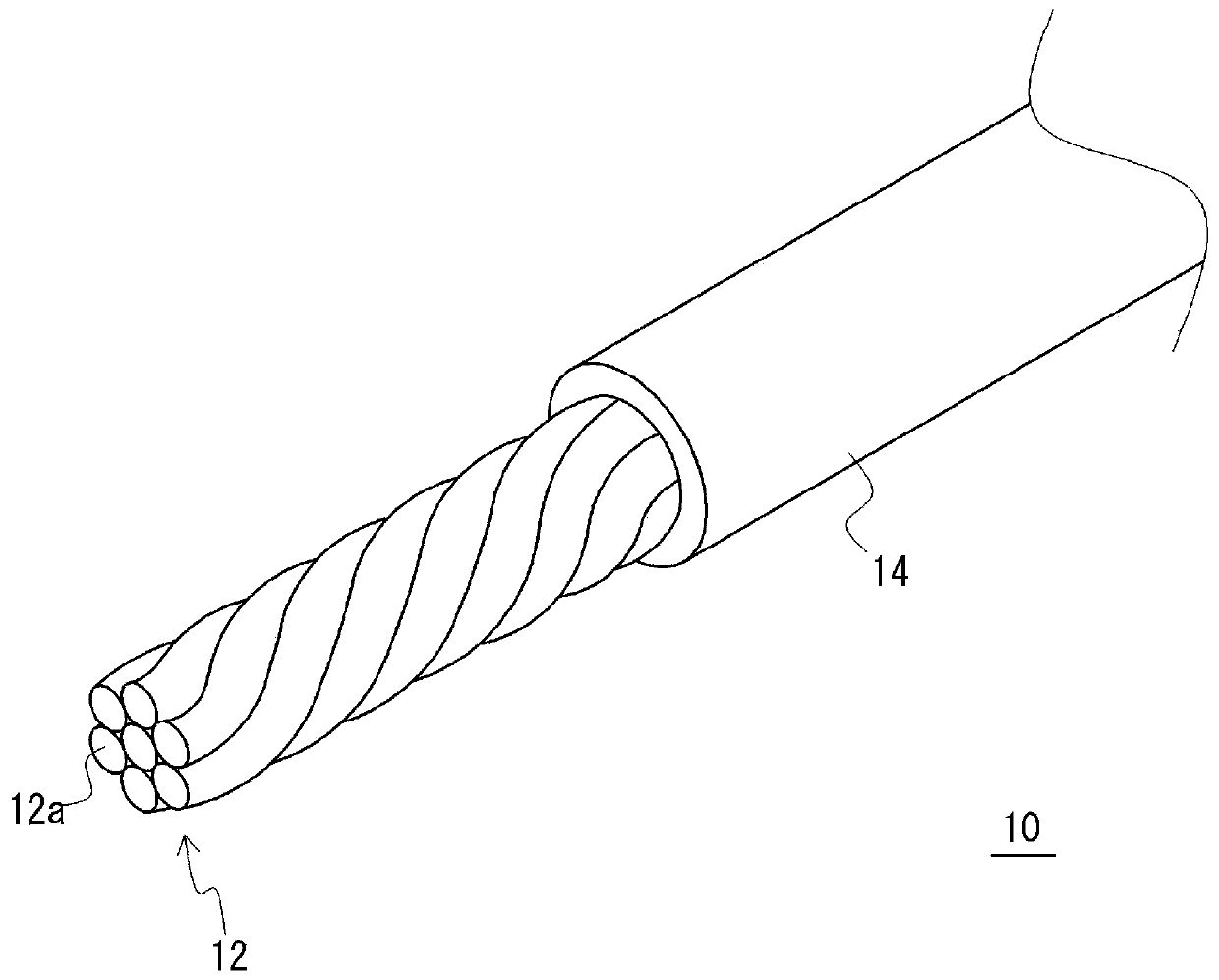

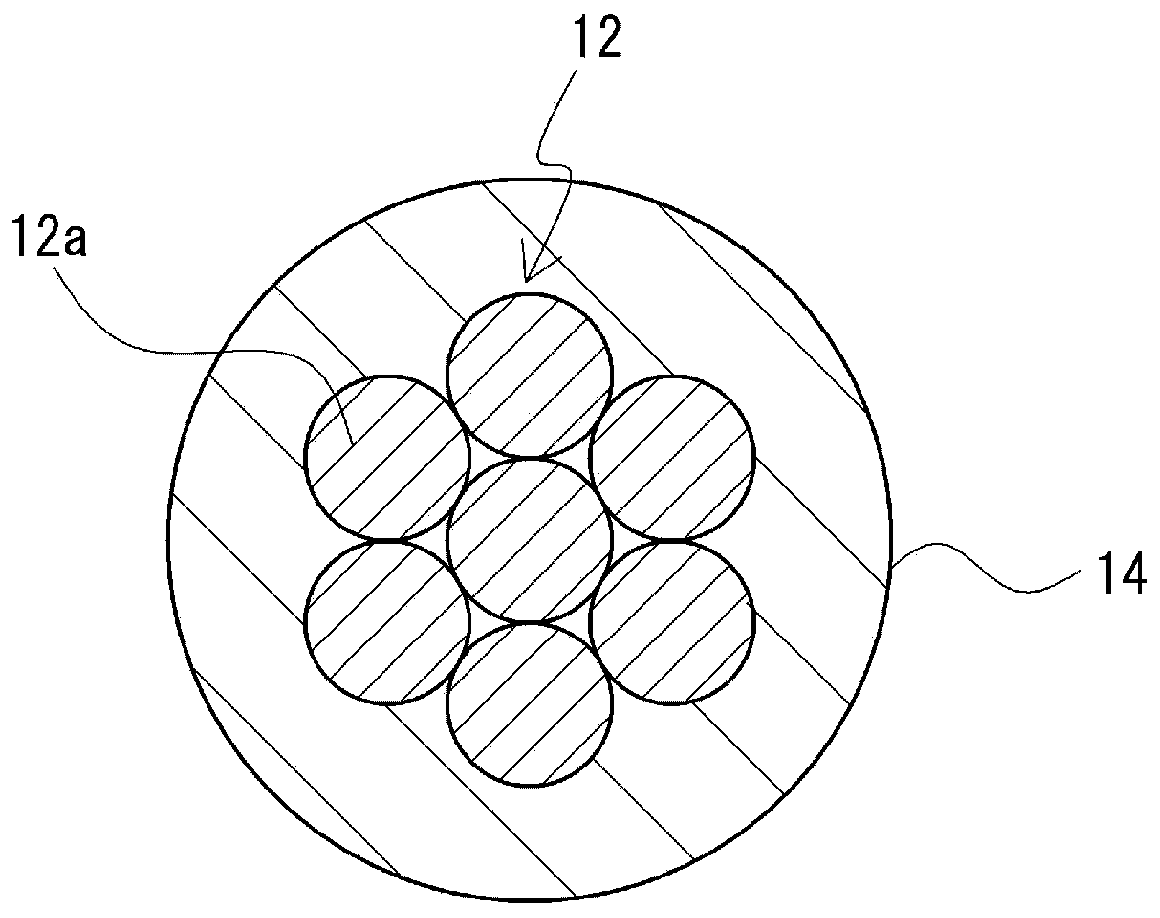

Provided are an insulated wire comprising an insulating sheath that is formed from a resin composition with high wear resistance, and a wire harness comprising this sort of insulated wire. Provided isan insulated wire 10 having a wire conductor 12 and an insulating sheath 14 that covers the periphery of the wire conductor 12, wherein the insulating sheath 14 is formed from a resin composition that has a thermoplastic polyurethane elastomer as a primary component. Also provided is a wire harness including this sort of insulated wire 10. The thickness of the insulating sheath 14 is preferably less than 0.7mm.

Description

technical field [0001] The present invention relates to an insulated wire and a wire harness. More specifically, it relates to an insulated wire that can be suitably used for electrical connection of automobiles and the like, and a wire harness including such an insulated wire. Background technique [0002] Insulated electric wires are generally required to have high flexibility in order to ensure wiring properties. Especially in the case of insulated wires used for electrical connections in automobiles, wiring in a limited space or wiring in complicated paths has increased as automobiles have become more functional and high-performance in recent years. Increased demands on flexibility. [0003] As a means of improving the flexibility of insulated wires, a method of reducing the thickness of the insulating coating layer may be adopted. Thinning the insulating coating also contributes to space saving by reducing the diameter of the insulated wire. However, if the insulatin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): H01B7/04H01B3/30H01B7/00H01B7/02

CPCH01B3/302H01B3/30H01B7/0045H01B7/0275

Inventor 古川丰贵荒木谦一郎

Owner AUTONETWORKS TECH LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap