Engine rotational speed variation amount detecting device and engine control device

A technology of rotation speed and detection device, which can be used in engine control, ignition energy generated by generator, engine ignition, etc., and can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

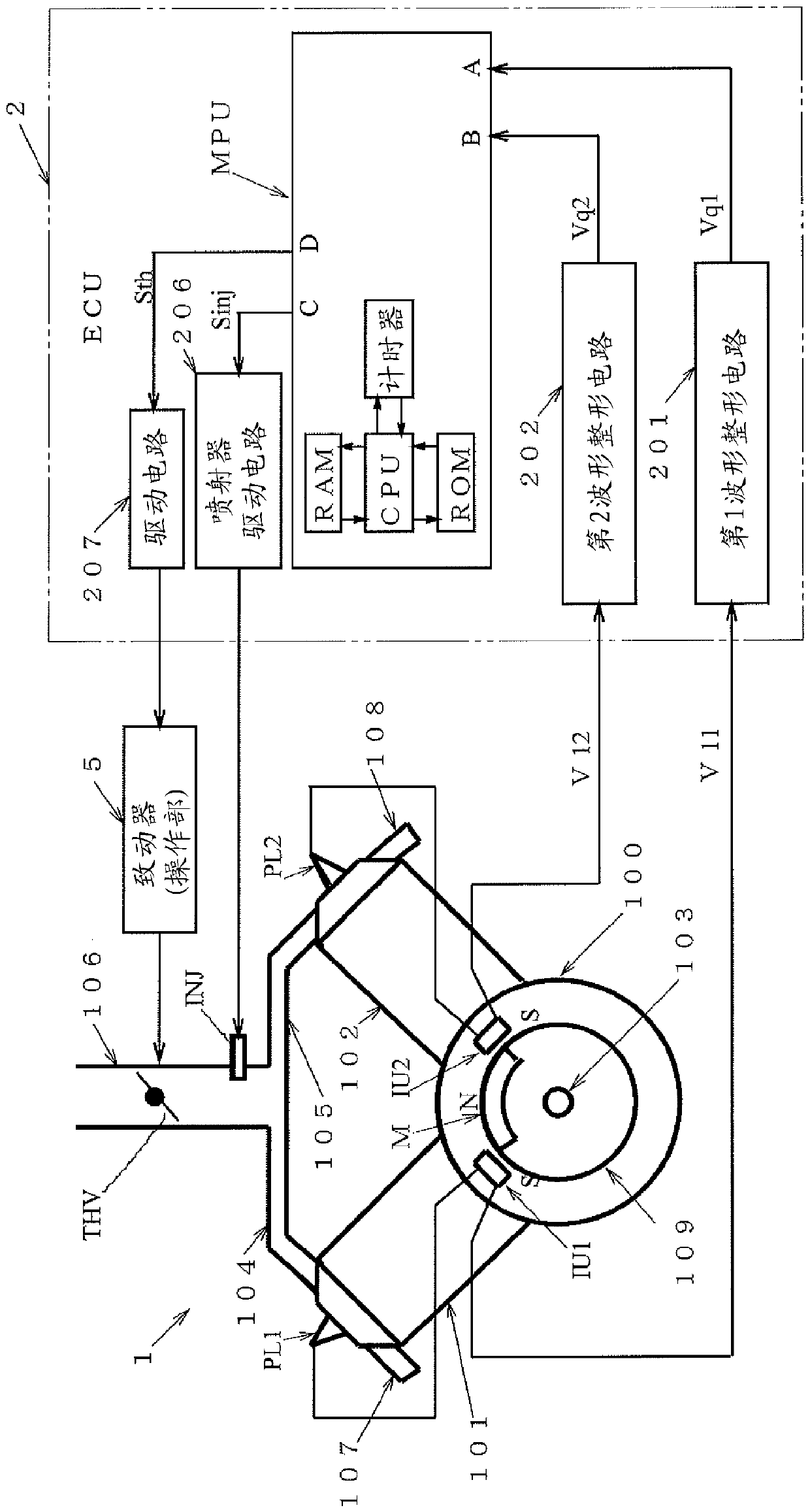

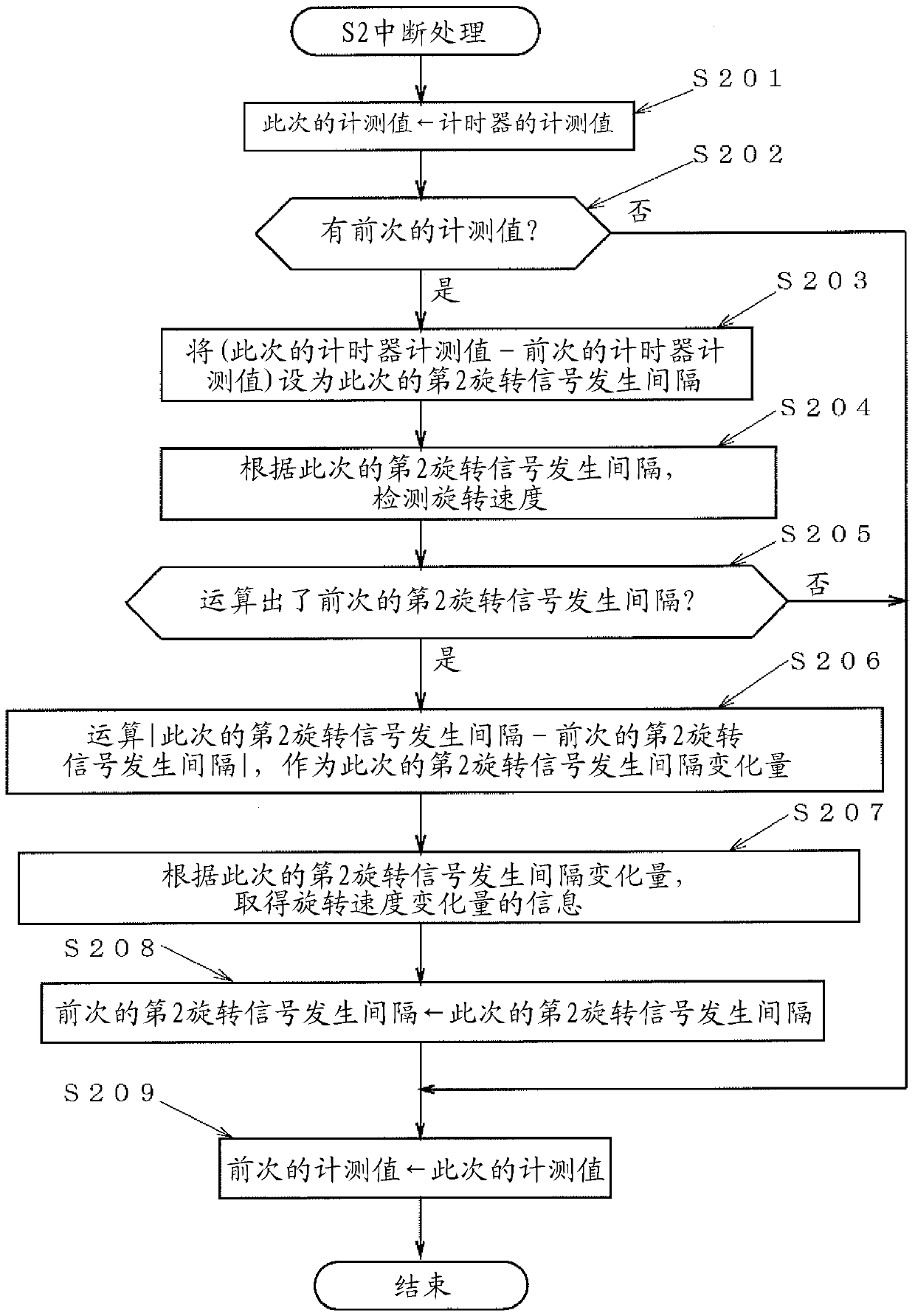

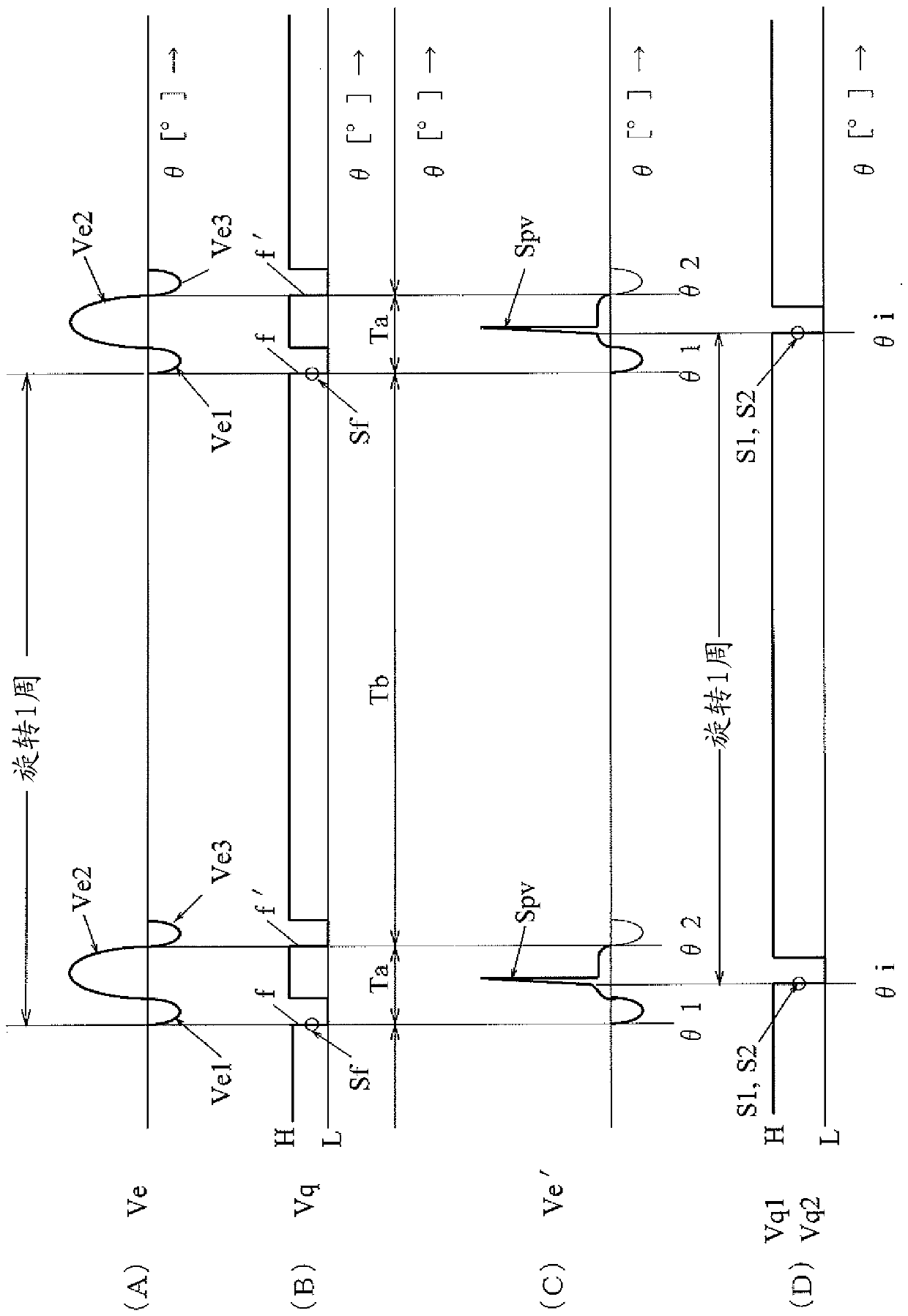

[0042] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0043] The present invention can be applied to a multi-cylinder four-cycle engine having n cylinders (n is an integer equal to or greater than 2). In the embodiments shown below, it is assumed that the engine is a V-type 2-cylinder 4-cycle engine.

[0044] In a 4-cycle engine, at the normal ignition position set near the crank angle position (rotation angle position of the crankshaft) when the piston reaches the top dead center in the compression stroke, spark discharge is generated by the spark plug attached to the cylinder of the engine, Since the fuel in the cylinder is combusted, the fuel in the cylinder is combusted only once during two revolutions of the crankshaft. Therefore, in order to rotate the engine, it is sufficient to ignite the ignition device only once during two revolutions of the crankshaft. To determine whether the stroke that ends at top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com