Expansion bolt with clamping block

A technology of expansion bolts and clamps, which is applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems that the nuts cannot be fully tightened, and the bolt body and the outer sleeve cannot be stuck, so as to achieve low production costs, prevent mutual rotation, Ease of tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

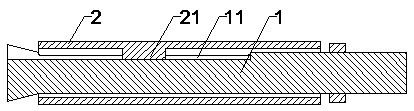

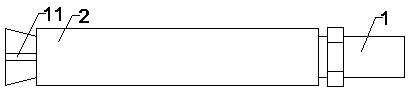

[0011] Such as figure 1 and figure 2 As shown, the expansion bolt with blocks of the present invention includes a bolt body 1 and an outer casing 2, the large end side of the bolt body 1 is provided with an axial slide groove 11, and the inner wall of the outer casing 2 is provided with an adapted sliding groove. block 21, so that the slider 11 snaps into the chute 21 and is slidably connected with the chute 21. Those skilled in the art should understand that, the device is provided with a chute 11 on the outer wall of the bolt body 1, and the chute should extend from the large end to the small end of the bolt body 1 and be arranged parallel to its axis. An adapted slider 21 is arranged on the inner wall of the middle part, and the slider 11 is snapped into the chute 21, so that when the nut on the bolt body 1 is screwed, since the slider 21 is always stuck in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com