Roller type kinetic energy converter

A conversion machine, drum type technology, applied in the direction of reaction engine, engine components, machine/engine, etc., can solve the problems of reduced kinetic energy loss, complex structure, low kinetic energy conversion efficiency, etc., to achieve reduced kinetic energy loss, simple equipment structure, The effect of improving kinetic energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The utility model relates to a one-way drum type kinetic energy conversion machine.

[0042] The one-way drum type kinetic energy conversion machine is suitable for the kinetic energy conversion of one-way water flow, for example, it is suitable for installation in rivers, reservoirs and sea current environments with one-way flow in the ocean. At present, the world's largest ocean current energy generator has an installed capacity of 3.4 megawatts. According to preliminary calculations, the installed capacity of a single unit of the present invention can reach more than 10 megawatts in an ocean current environment; in the environment of rivers and reservoirs, the installed capacity of a single unit can be even larger.

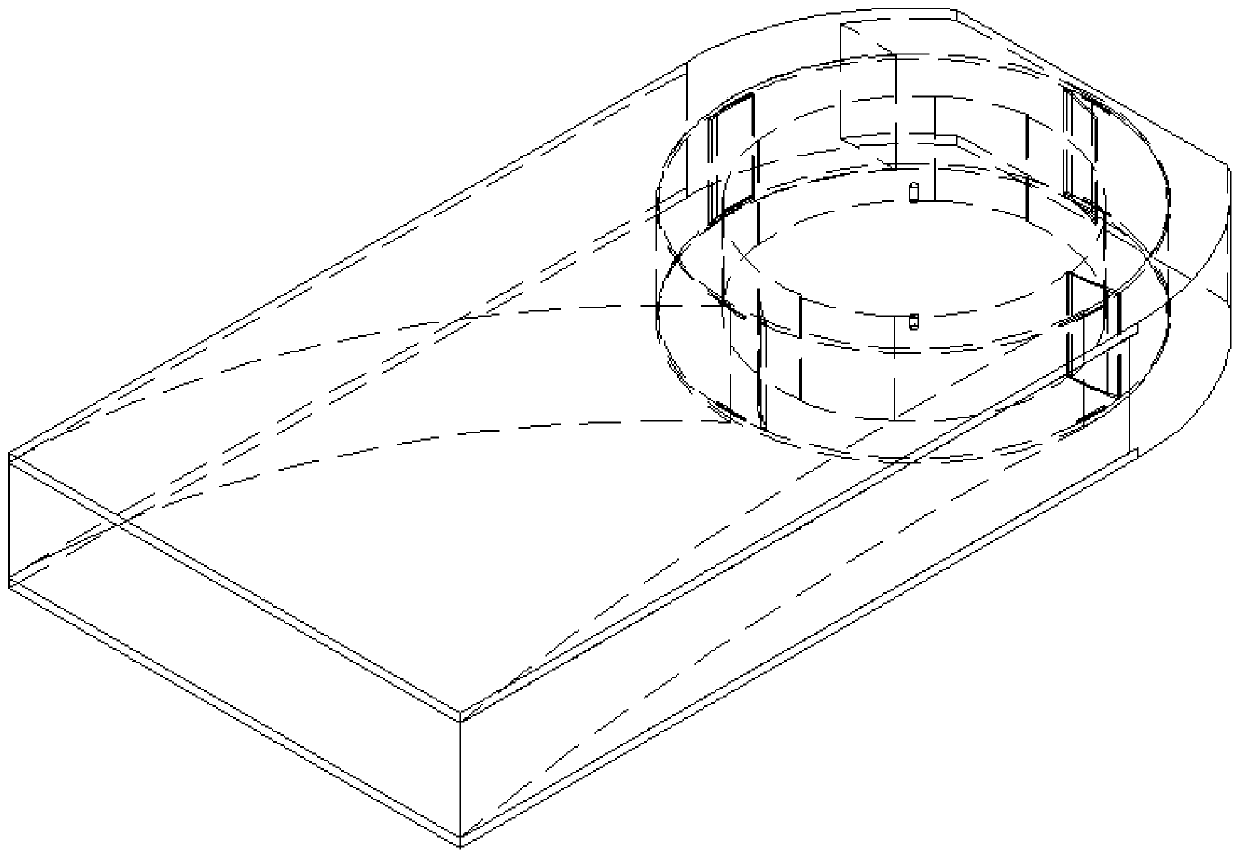

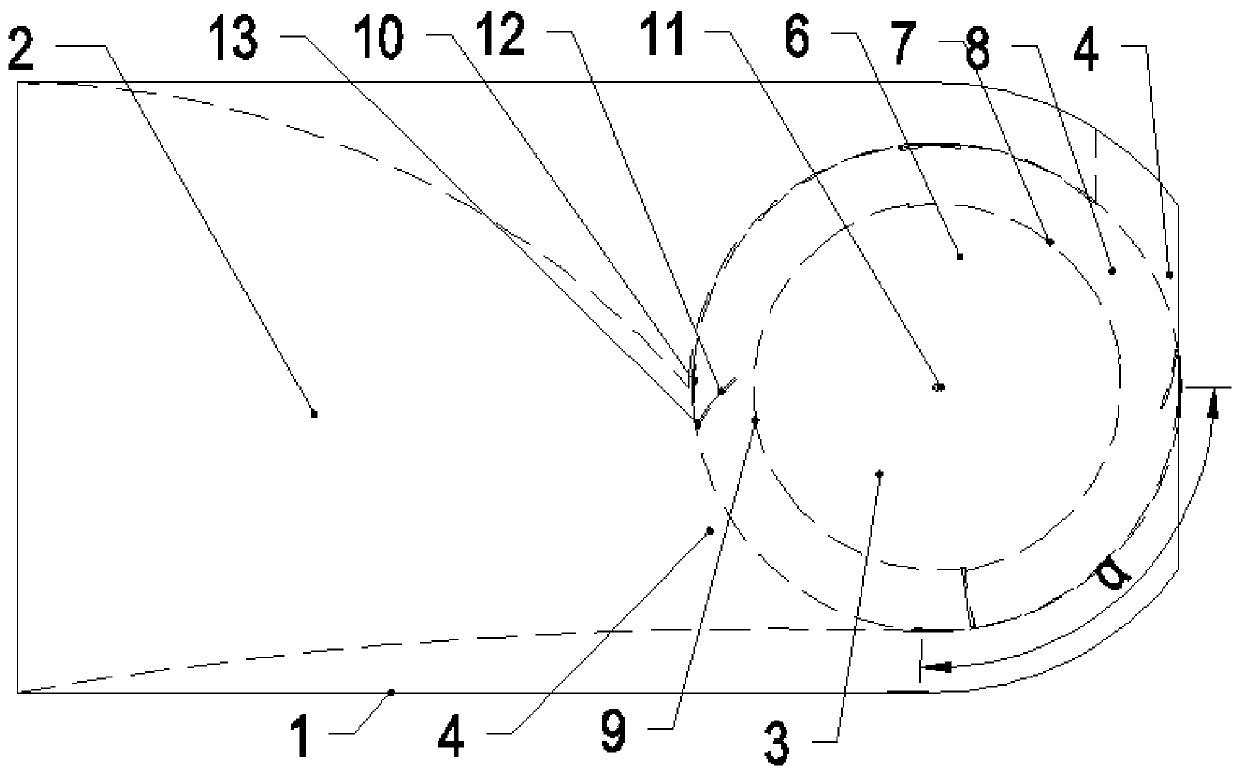

[0043] like figure 1 , figure 2 As shown, the one-way kinetic energy conversion machine includes a casing 1 and a rotor 6 . like Figure 7 , Figure 8 As shown, the internal structure of the housing 1 includes the diversion channel 2 and the rotor ...

Embodiment 2

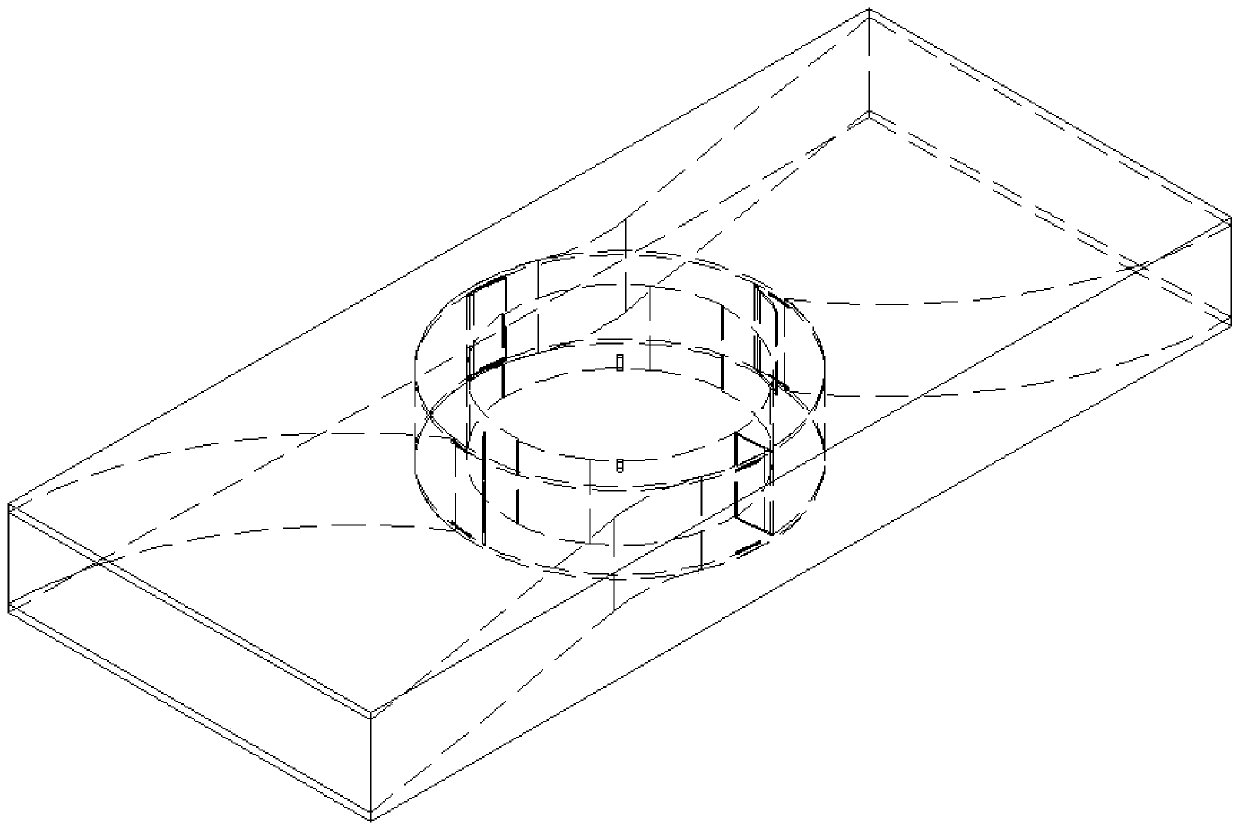

[0053] A two-way drum type kinetic energy conversion machine.

[0054] In the ocean, the existing sea (water) flow energy conversion equipment that utilizes ocean current energy to generate electricity, in addition to large energy loss, low kinetic energy conversion efficiency, and complex equipment structure, also has defects such as difficult installation and small installed capacity of a single machine. For this reason, the present invention has also designed a kind of two-way drum type kinetic energy conversion machine. In the environment of ocean tidal flow, according to the characteristic that the direction of tidal flow changes regularly in opposite directions, the bidirectional drum type kinetic energy conversion machine can receive the kinetic energy of sea (water) flow from two opposite directions for conversion. At present, the installed capacity of the world's largest ocean current energy generator is 3.4 MW. According to preliminary calculations, in the current e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com