Conveying and cover mounting device applying high-dimensional data detection

A high-dimensional data and capping technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problem of inability to take into account the interaction of different components, measurement data correlation, inaccurate transportation, and inability to ensure products. Problems such as precise coordination with the capping station

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

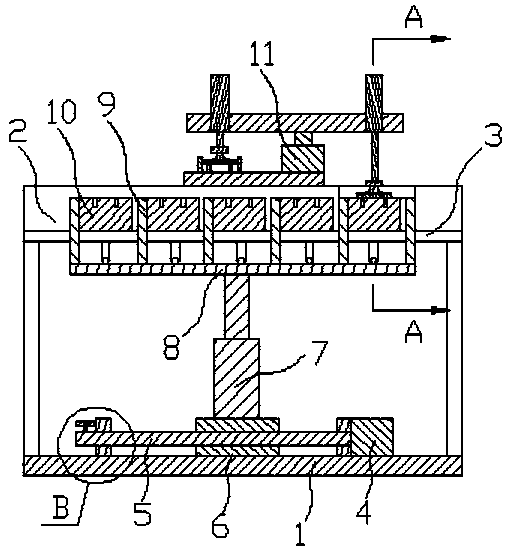

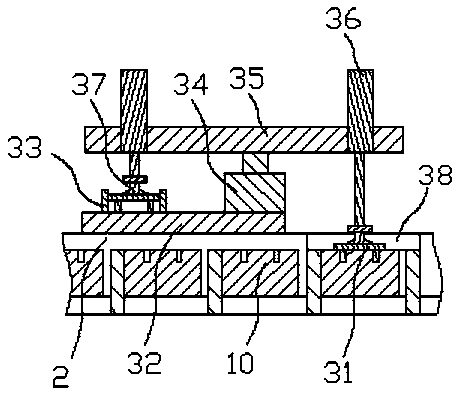

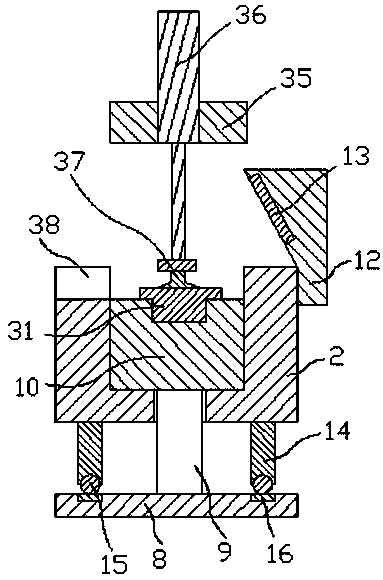

[0017] like Figure 1-3 As shown, the specific structure of the present invention is: a conveying and capping equipment using high-dimensional data detection, including a frame 1 and a conveying trough 2, and the middle of the bottom of the conveying trough 2 is provided with an inlet 3 consistent with its direction. , the feeding inlet 3 is equipped with a feeding device for feeding the products 10 in the conveying tank 2 at a fixed distance, and a capping device 11 is arranged above the conveying tank 2, and the capping device 11 includes a The cover mounting seat 32 above the groove 2, the cover mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com