Speed increasing telescopic mechanism of boom

A technology of telescopic mechanism and jib, applied in cranes and other directions, can solve problems such as affecting the weight of tree grabbing and lifting, affecting the efficiency of grabbing forest trees, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

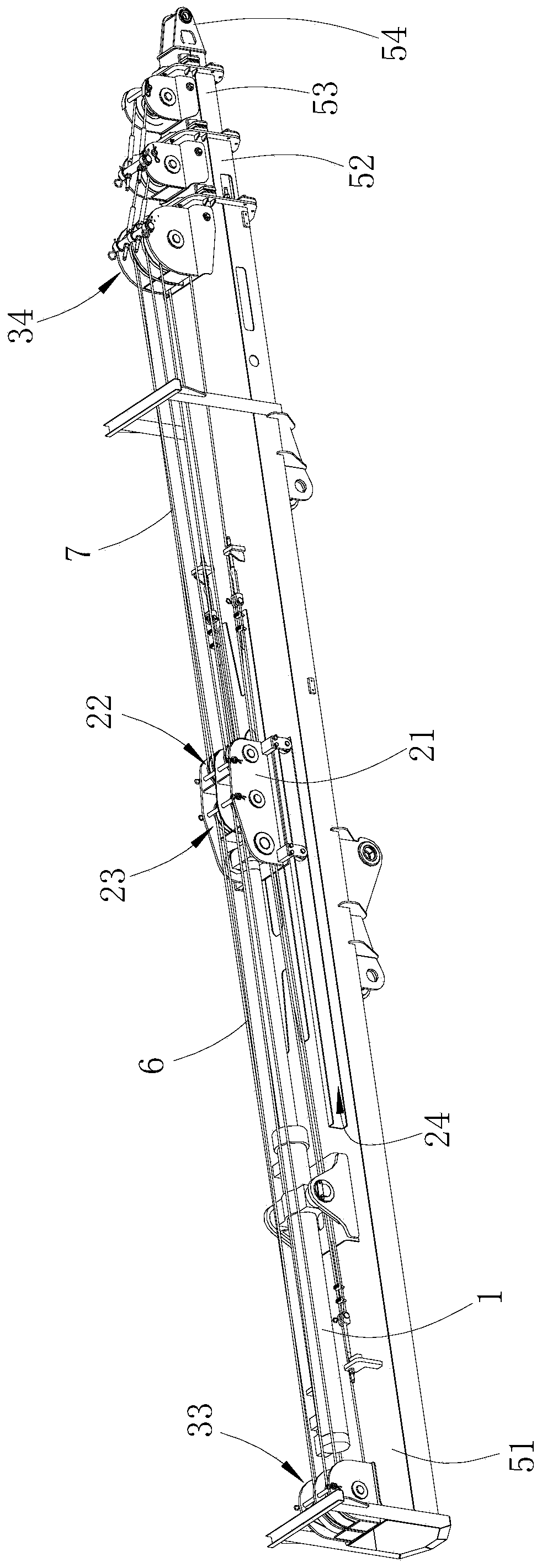

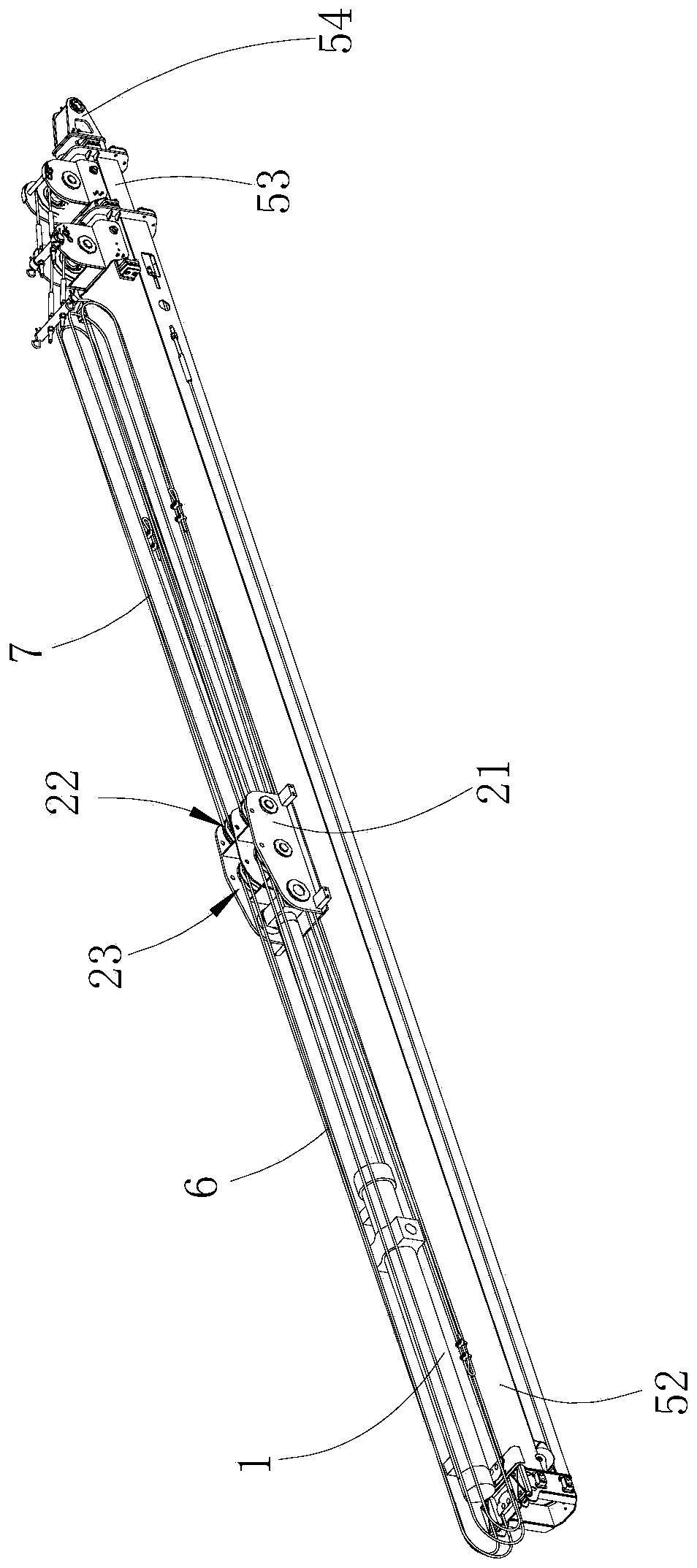

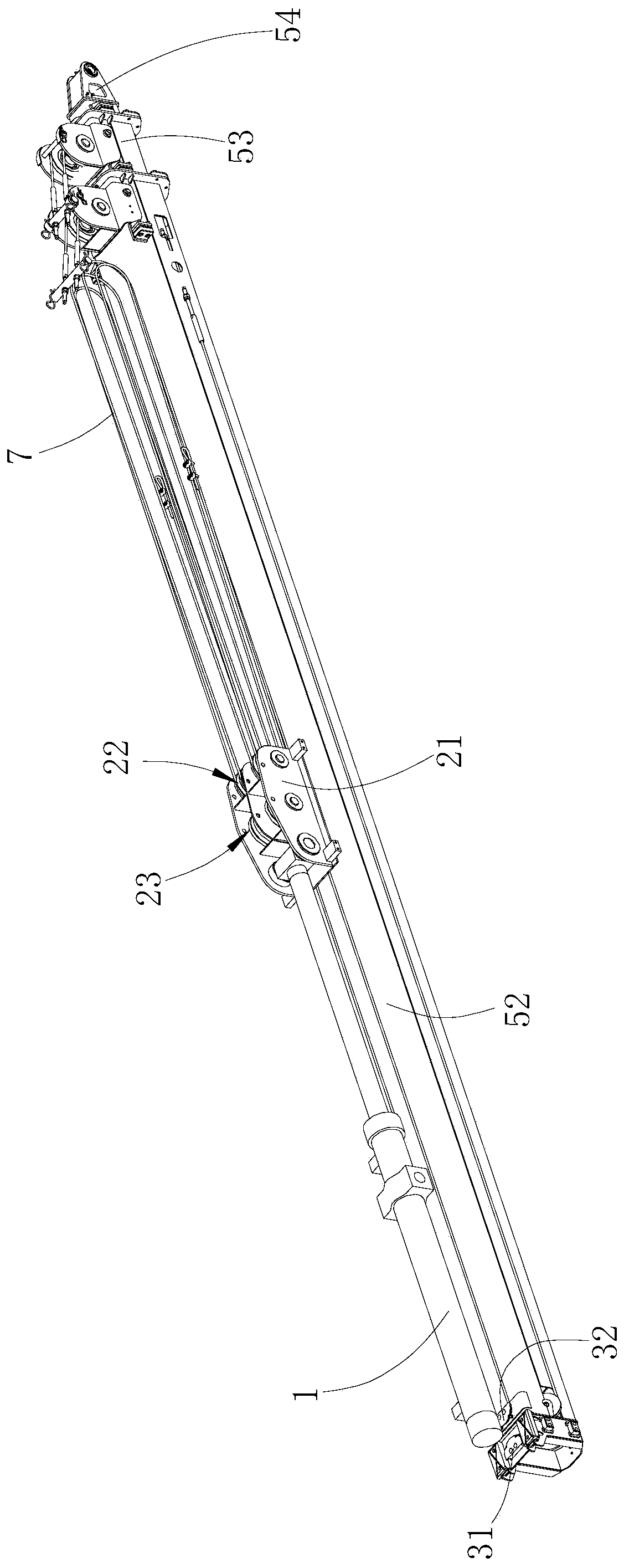

[0025] Such as Figures 1 to 5 Shown (in order to clearly understand the internal structure of the speed-up telescopic mechanism of the boom, figure 2 The master section arm 51 is omitted in image 3 In the main section arm 51 and the retraction wire rope 6 are omitted, Figure 4 The main section arm 51 and the extended steel wire rope 7 are omitted in the Figure 5 Omit the main section arm 51, the second section arm 52, the telescopic oil cylinder 1, the pulley assembly, the winding assembly, stretch out the wire rope 7 and retract the wire rope 6).

[0026] The jib of the crane in this embodiment includes a main section arm 51, a second section arm 52 and two secondary section arms. Inside, the two sub-section arms are three-section arms 53 and four-section arms 54 respectively.

[0027] The speed-up telescopic mechanism of the boom comprises a telescopic oil cylinder 1, a pulley assembly, a winding assembly, a steel wire rope 7 stretched out, a retraction steel wire r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com