Special-shaped steel belt and steel aluminum composite conductor rail

A special-shaped steel belt and steel belt technology, which is applied in the direction of power rails, power lines, transportation and packaging, etc., can solve the problem of inconsistent width of stainless steel belts, and achieve the goal of increasing the effective contact surface width, increasing the proportion, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

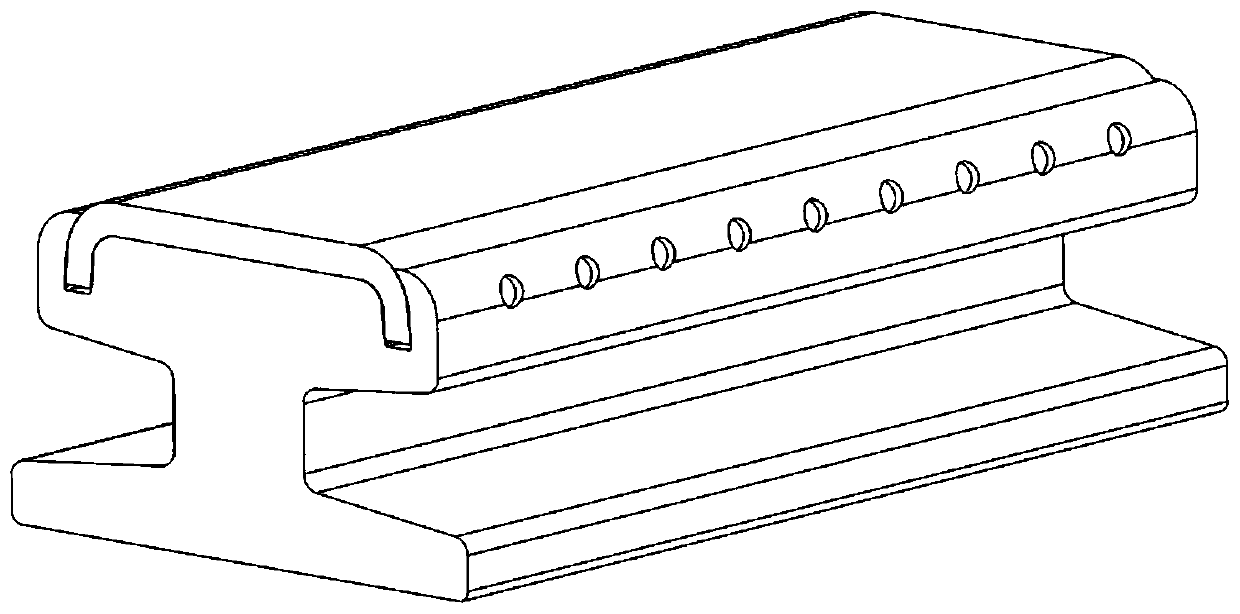

[0030] See image 3 , the embodiment of the present invention provides a special-shaped steel strip, the steel strip has a π-shaped cross section, and mainly includes a steel strip body 1 and two supporting legs 2, and the two supporting legs 2 are symmetrically located below the steel strip body 1, And the outer sides of the two supporting legs 2 are provided with circular arc grooves 3 along the length direction of the steel strip.

[0031] Further, the first tooth grooves 4 are evenly distributed on the outside of the lower end of the support leg 2 along the length direction of the steel strip, and the first tooth grooves 4 communicate with the circular arc grooves 3 .

[0032] Further, the first alveolar 4 is any one of triangle, rectangle and trapezoid.

[0033] The steel strip is integrally formed by hot rolling, which improves production efficiency.

Embodiment 2

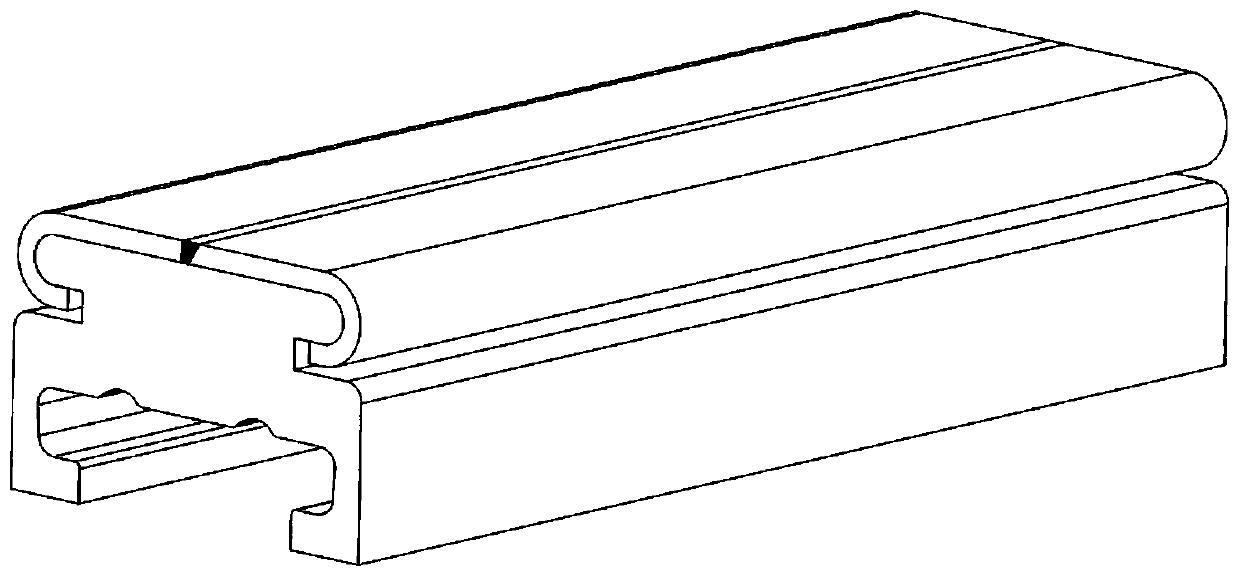

[0035] See Figure 4 , the embodiment of the present invention provides a special-shaped steel strip, the steel strip has a π-shaped cross section, and mainly includes a steel strip body 1 and two supporting legs 2, and the two supporting legs 2 are symmetrically located below the steel strip body 1, And the outer sides of the two supporting legs 2 are provided with circular arc grooves 3 along the length direction of the steel strip.

[0036] Further, second tooth grooves 5 are evenly distributed on the lower surfaces of both sides of the steel strip body 1 along the length direction of the steel strip.

[0037] Further, the second tooth groove 5 is any one of triangle, rectangle and trapezoid.

[0038] It should be noted that the steel strip can not only be integrally formed by hot rolling to improve production efficiency; of course, it can also be formed by other forming methods.

Embodiment 3

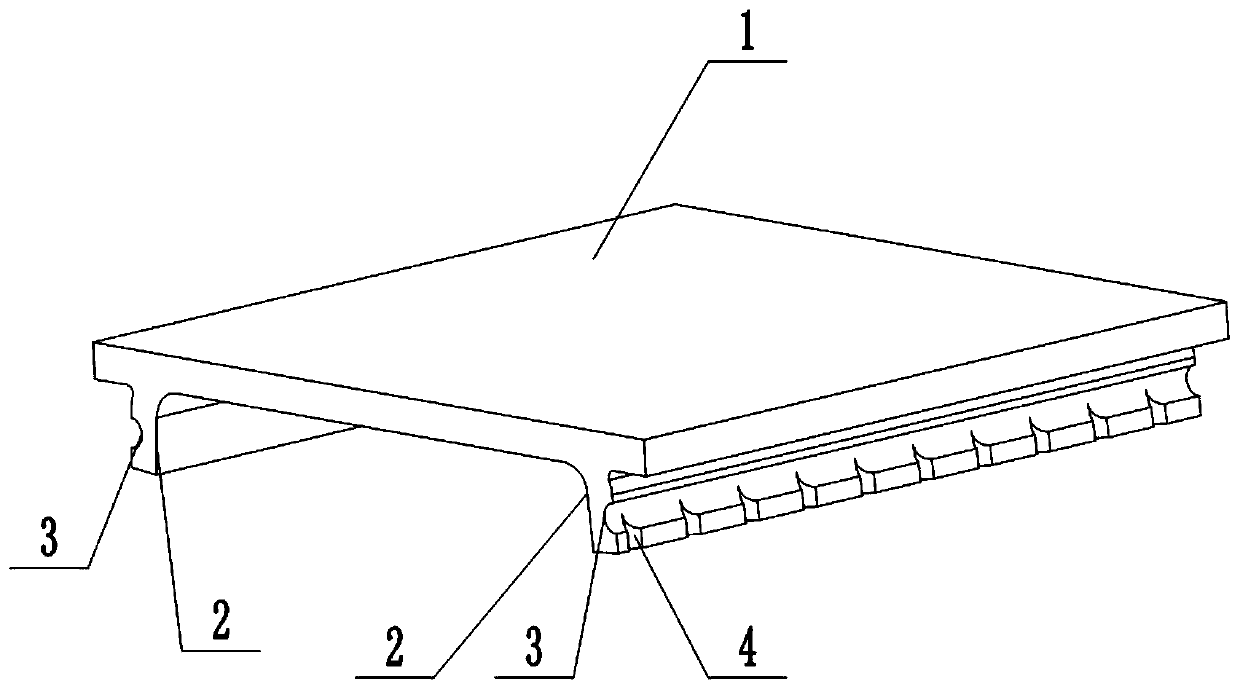

[0040] See also image 3 and Figure 5 , the embodiment of the present invention provides an "I"-shaped steel-aluminum composite conductive rail, including an "I"-shaped aluminum rail 6 and a steel belt 7, which is characterized in that the two sides of the rail top of the aluminum rail 6 are symmetrically made There are two grooves 8, and the outer walls of the two grooves 8 have circular arc protrusions 9 symmetrically along the length direction; the cross section of the steel strip 7 is π-shaped, including the steel strip body 1 and two supporting legs 2; The two supporting legs 2 are symmetrically located below the steel belt body 1, and the outer sides of the two supporting legs 2 have arc grooves 3 along the length direction of the steel belt 7; the steel belt 7 is buckled on the rail top of the aluminum rail 6, and the two The two supporting legs 2 are respectively inserted into two grooves 8, and the arc protrusions 9 are embedded in the arc grooves 3 by extruding the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com