System and method for adjusting flexibility of coal-fired unit using water supplementing tanks

A technology for coal-fired units and adjustment systems, applied in mechanical equipment, steam engine installations, machines/engines, etc., can solve problems such as cavitation, water pump cavitation, working fluid and heat loss, and achieve simple equipment structure and reduce factory use. Electricity, the effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

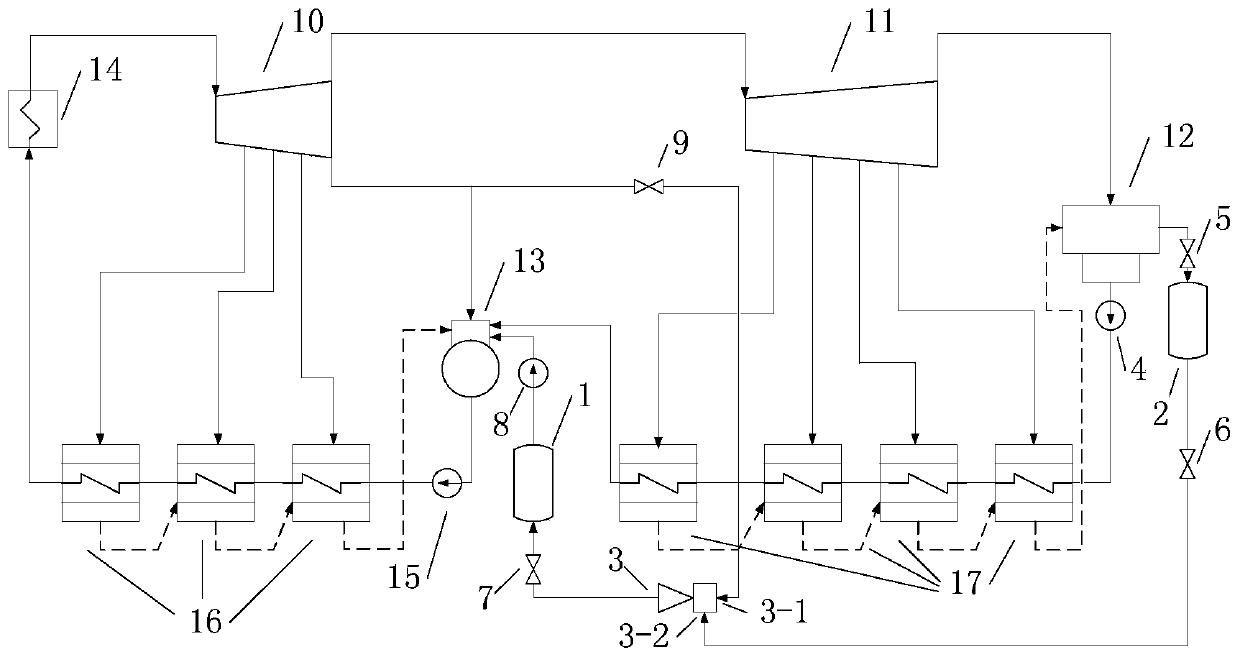

[0018] The invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, the present invention is a flexible adjustment system for coal-fired units using a water supply tank. The boiler 14 is connected to the inlet of the high-pressure cylinder 10, and the steam extraction ports of the high-pressure cylinder 10 are connected to the corresponding steam extraction inlets of the high-pressure heat exchanger 16. , the exhaust port of the high-pressure cylinder 10 is connected to the inlet of the low-pressure cylinder 11, the steam extraction ports of the various levels of the low-pressure cylinder 11 are respectively connected to the corresponding extraction steam inlets of the low-pressure heat exchanger 17, and the exhaust port of the low-pressure cylinder 11 is connected to the inlet of the condenser 12 , the water supply outlet of the condenser 12 is connected with the water supply inlet of the low-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com