A small formwork support system and construction technology for fair-faced concrete decorative walls

A technology of fair-faced concrete and formwork support, applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem that the unit formwork has obvious joints and cannot be continuous. Pouring, inability to realize the fine construction of decorative concrete, etc., to achieve the effect of high construction accuracy and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

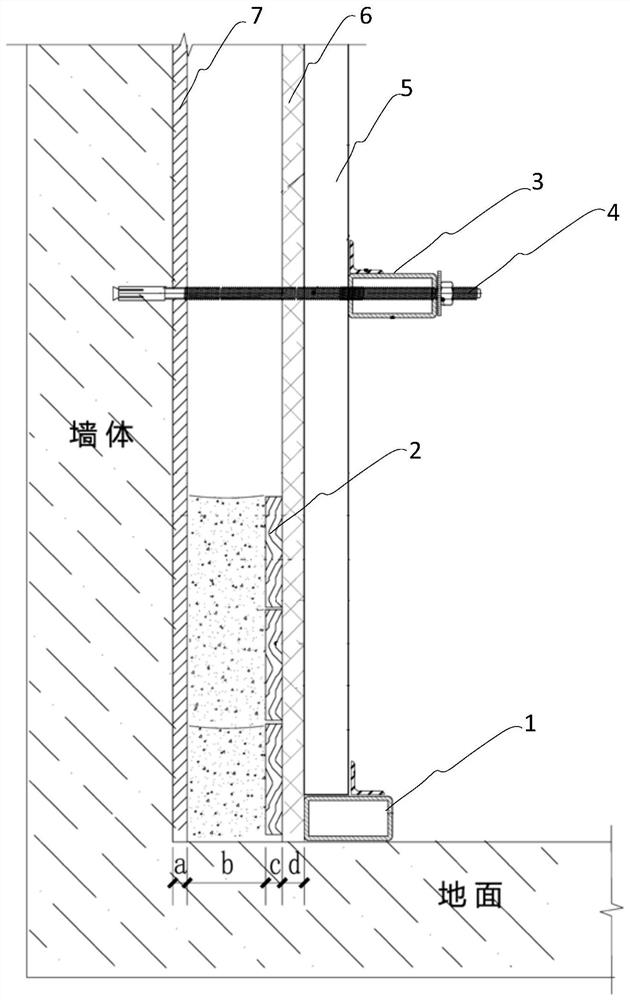

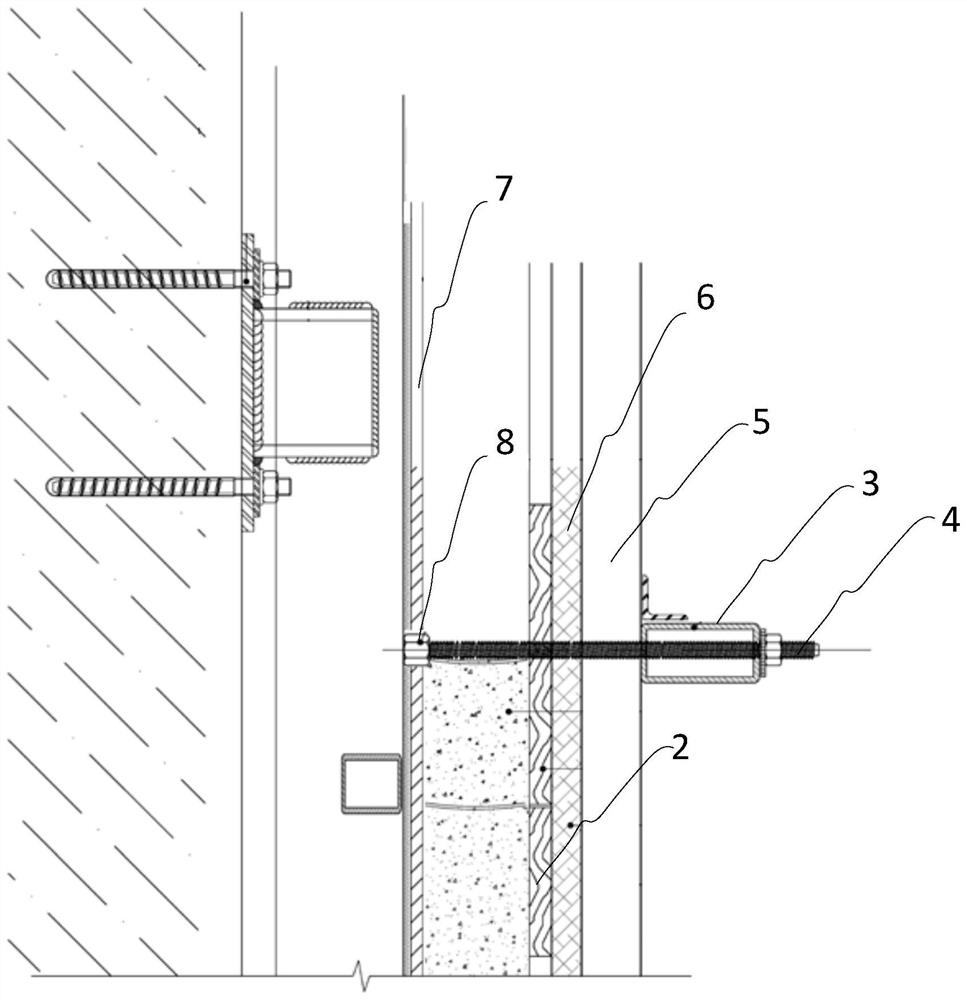

[0056] One of the cores of the present invention is to provide a small formwork support system for clear-water concrete decorative walls. The structural design of the small formwork support system for clear-water concrete decorative walls enables the fine construction of decorative concrete on any working surface, and there is no obvious difference after pouring. The purpose of seams.

[0057] Another core of the present invention is to provide a small formwork construction process for clear-water concrete decorative walls based on the above-mentioned small formwork support system for clear-faced concrete decorative walls.

[0058] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com