A device for conveying and sorting packaging bags after they are cut

A technology for sorting devices and packaging bags, which is applied in the directions of packaging, transportation and packaging, bag making operations, etc., can solve the problems of high labor intensity, easy scratching of the packaging bags, and potential safety hazards, and achieves reasonable structural design and reduced The process of manual participation, the effect of convenient collection and sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

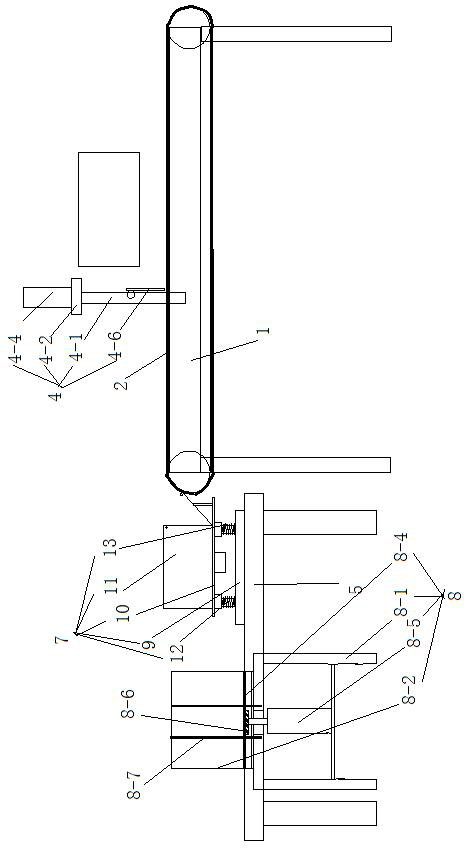

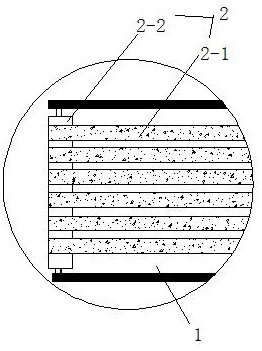

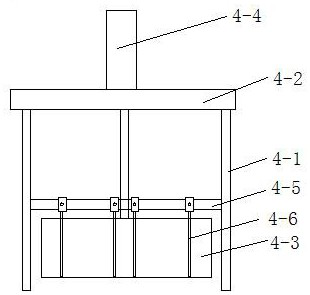

[0022] See attached picture.

[0023] A conveying and sorting device after packaging bags are cut, including a material receiving platform 1 erected under the cutting machine, characterized in that: the material receiving platform 1 is distributed with a circular conveyor belt arranged along the length direction of the material receiving platform 2. The upper end surface of the circulating conveyor belt 2 is close to the material receiving platform 1, and the position above the material receiving platform 1 close to the cutting machine is provided with a packaging bag blanking limit mechanism 4. The discharge end frame is provided with a finishing platform 5, and the discharge end frame of the circular conveyor belt 2 on the said finishing platform 5 is provided with a vibrating type material receiving and finishing mechanism 7, and one side of the said finishing platform 5 is provided with a material receiving frame discharging mechanism 8 , the material receiving frame disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com