Device and method for installing and adjusting low-stress conductive seal of aviation light window

An adjustment method and low-stress technology, applied in gaskets/seals, installation, optics, etc., can solve the problem of large adjustment stress, difficulty in ensuring sealing performance, electromagnetic shielding performance, optical accuracy, and sealing requirements. Electromagnetic shielding requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

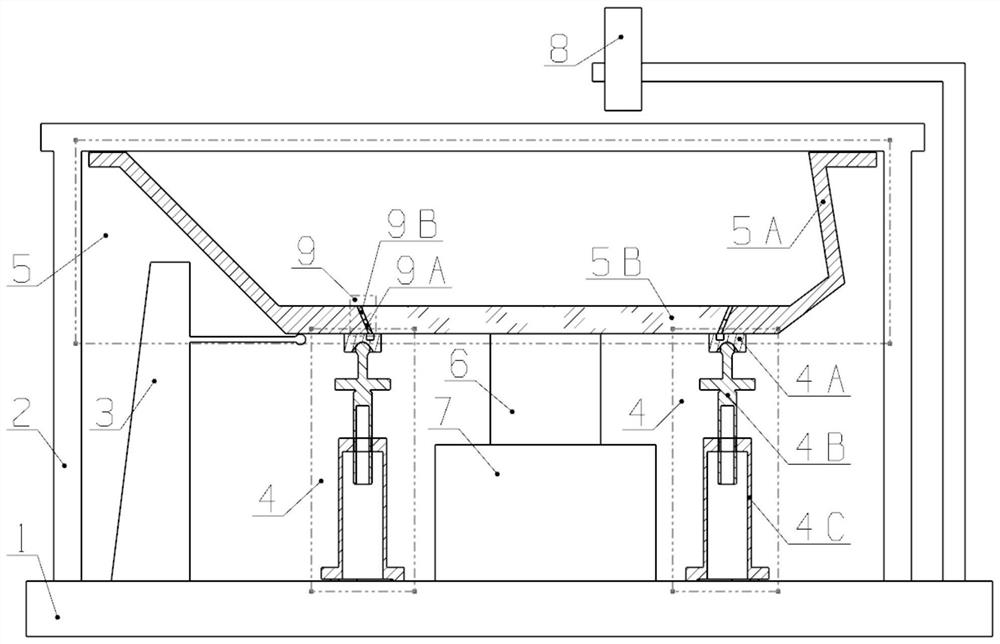

[0026] A low-stress conductive sealing installation and adjustment device for aviation light windows, the device includes an installation and adjustment platform 1, a light window frame fixing tool 2, an altimeter 3, a light window installation and adjustment reference tool 4, a light window support tool 6, a precision Electric control adjustment table 7, self-collimating light tube 8;

[0027] The assembly and adjustment platform 1 is the base during the entire assembly and adjustment process, and all the installation and adjustment testing equipment, assembly and adjustment tooling, and the aviation light window 5 to be installed and adjusted are installed on the assembly and adjustment platform 1;

[0028] The light window frame fixing tool 2 is used to support the light window frame 5A, and can adjust the angle of the surface to be assembled of the light wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com