Support method for releasing hard level surrounding rock high ground stress through buffering layer

A high ground stress and buffer layer technology, applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve problems such as support cracking and deformation, achieve low construction cost, simple operation, and ensure safety and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

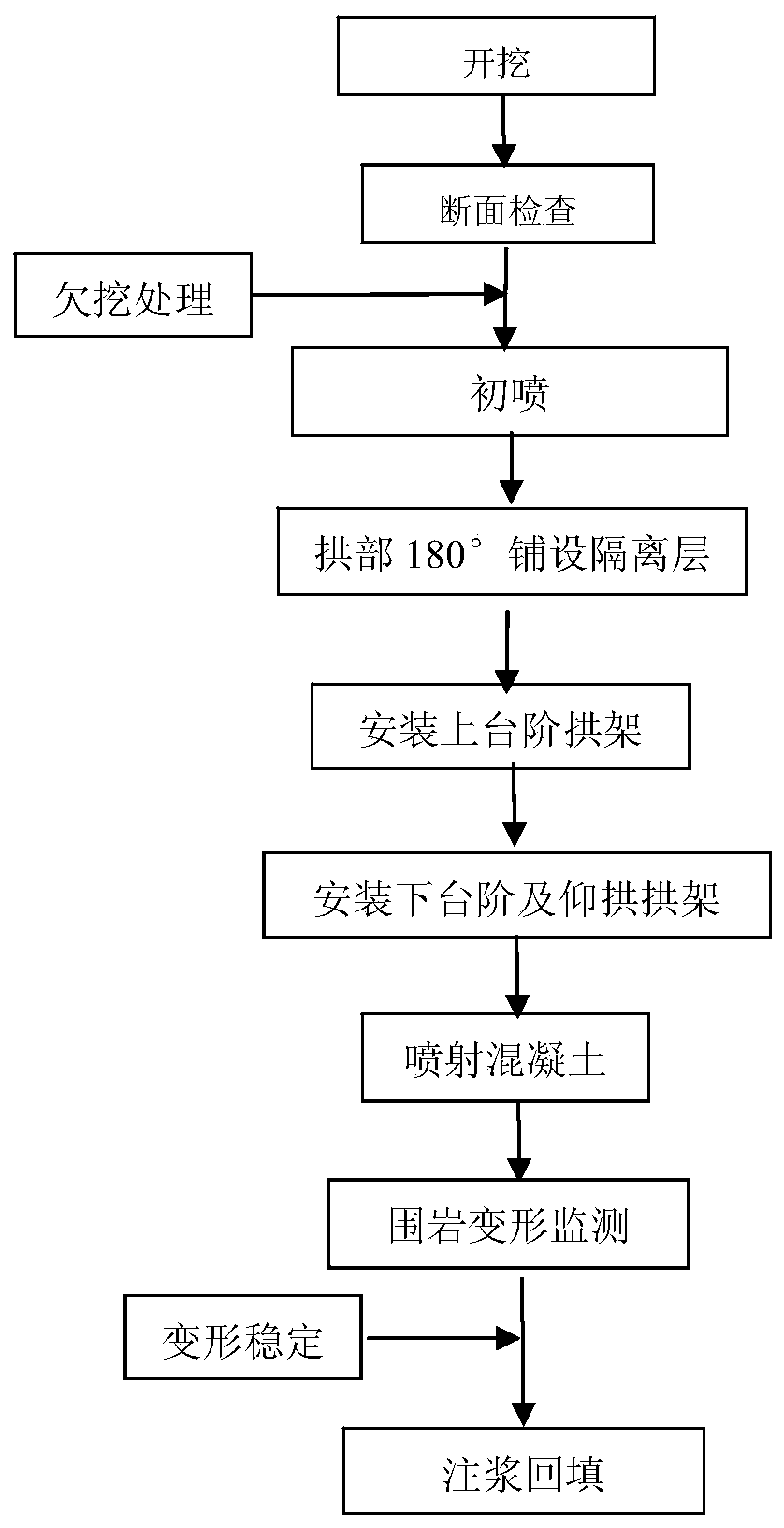

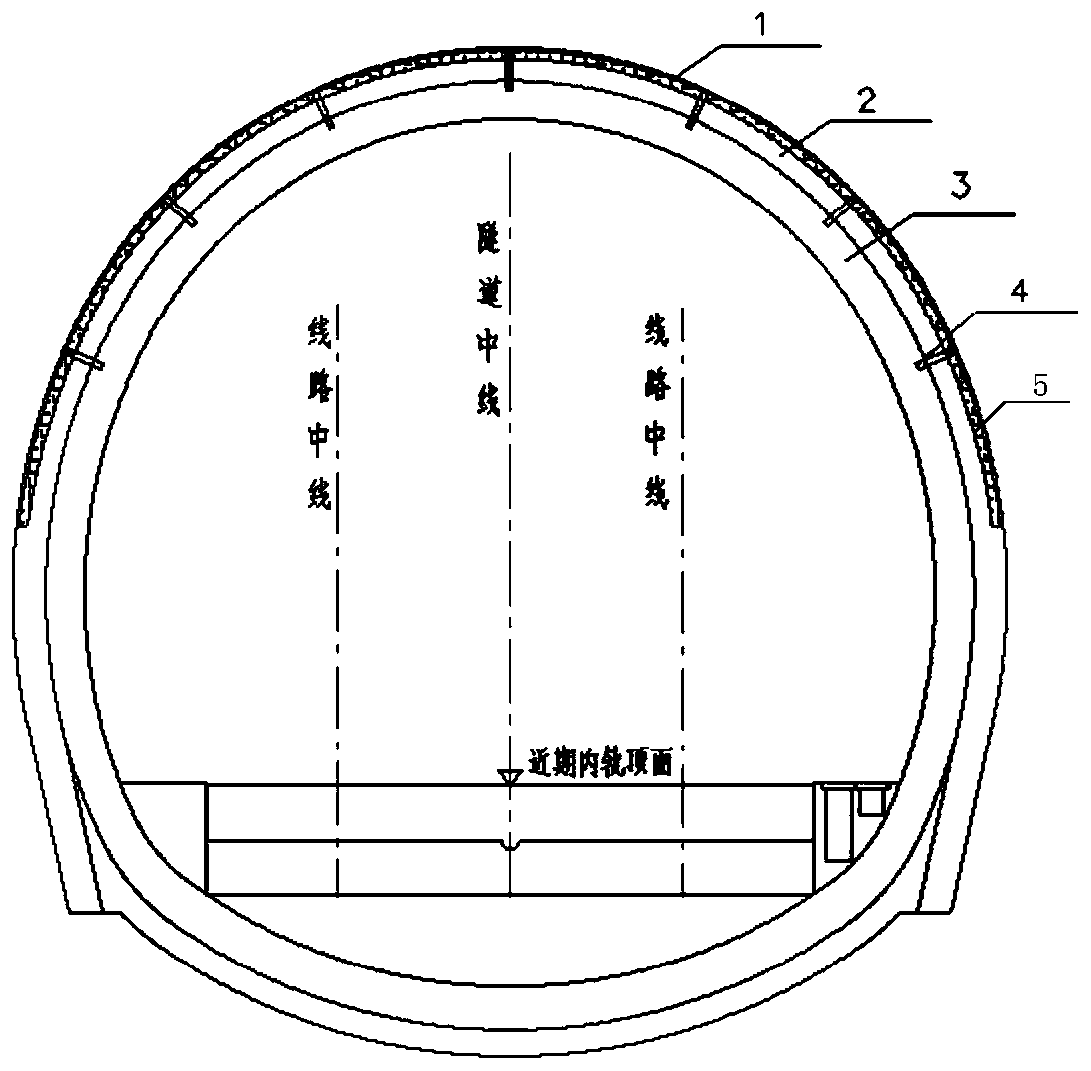

[0066] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 , 2 Shown, the support method of the present invention comprises the following steps:

[0067] Step 1. Construction preparation. Use the step method to excavate the tunnel. Divide the tunnel into two parts: the upper step and the lower step for excavation construction. The length of the upper step and the lower step are the same. The length of the upper and lower steps is 10-50m. When the surrounding rock grade is III and II, the length of the upper and lower steps is 3-10m, and the height of the upper step is 0.5m greater than that of the lower step.

[0068] Step 2. Use the drill and blast method for excavation construction:

[0069] Step 2.1, obtain blasthole parameters, blasthole parameters include blasthole type, blasthole position, blasthole quantity, blasthole depth and single-hole charge:

[0070] Step 2.11. Determine the die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com