A self-cleaning outdoor artificial stone slab and its preparation method

An artificial slate and cleaning technology, applied in the field of artificial stone, can solve the problems of difficult cleaning, low shrinkage, low water absorption, etc., and achieve the effects of less mold consumption, low shrinkage, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

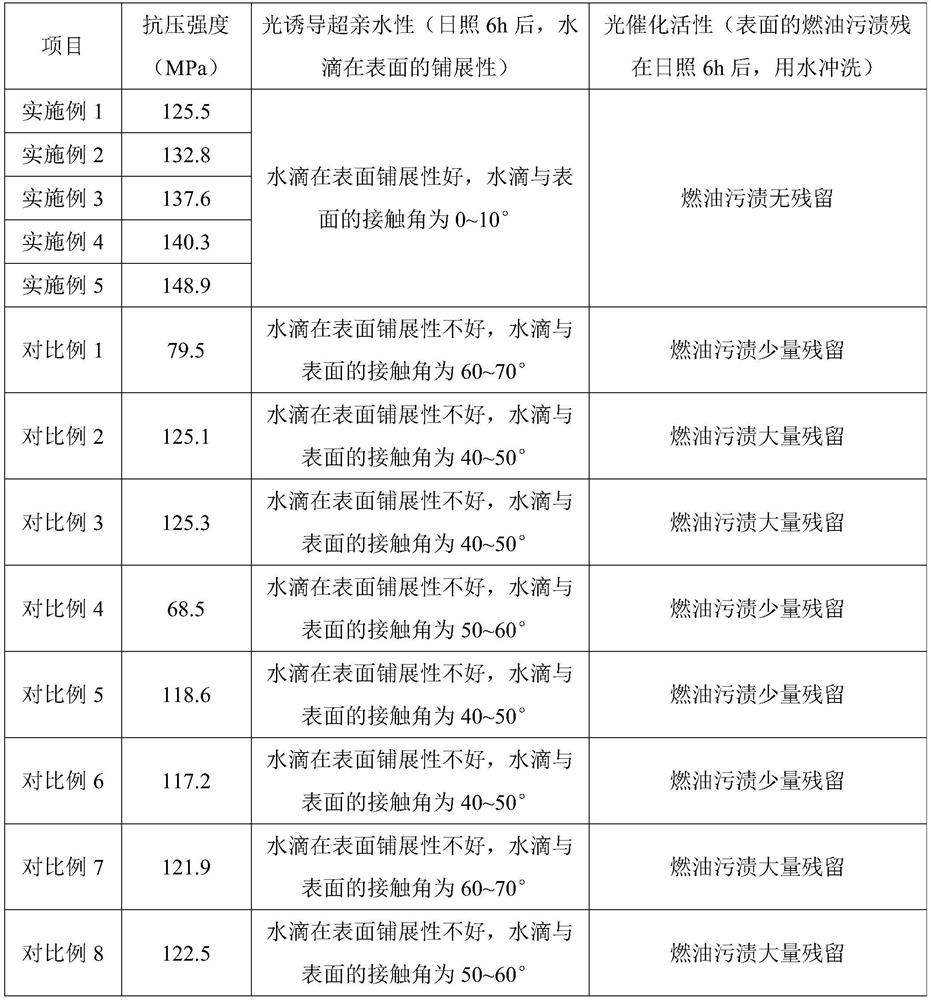

Examples

Embodiment 1

[0034]A self-cleaning outdoor use of artificial slate, prefabricated by ultra-high performance mineral powder of compressive strength 100 to 150 MPa, including a raw material component of the following weight fraction: mineral active powder 80 parts of the body, a titanium dioxide, 150 parts of the cleaning bone, 4 parts of nanosoxide, 0.5 hydrophobic agents, 10 water, 2 water reducer, 4 parts of the pigment.

[0035]The mineral active powder is blended with silica ash, ore powder, glass microbead, zeolite powder, mineral active powder zeolite, zeolite, mineral active powder, zeolite, silicon ash: mineral powder: glass microbeam: zeolite powder It is 1: 0.125: 0.75: 0.15: 0.1.

[0036]The titanium dioxide is atrial titanium dioxide having a particle size of 10 to 1000 nm. On the one hand, the photocatalytic function is utilized, and most of the organic contaminants is completely oxidized and degraded into an inorganic small molecule such as water and carbon dioxide. On the other hand Its ...

Embodiment 2

[0049]In addition to the formulations of the ultra-high performance mineral powder, other conditions are in Example 1.

[0050]The ultra-high performance mineral powder includes a raw material component of the following weight parts: 100 parts of mineral active powder, 13 parts of titanium dioxide, 220 parts of the cleaning bone, 8 parts of nanosoxide, 2 hydrophilic agents, 15 parts of water, 4 water reduction agents, 10 pigments.

Embodiment 3

[0052]In addition to the formulations of the ultra-high performance mineral powder, other conditions are in Example 1.

[0053]The ultra-high performance mineral powder includes a raw material component of the following weight parts: 85 mineral active powder, 9.5 parts of titanium dioxide, from 170 of the cleaning bone, 5 parts of nanosoxide, and 0.9 hydrophobic agents. 11 parts of water, 2.5 parts of water reducer, 5.5 copies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com