Rock slope TBS support method

A slope and rock technology, applied in the field of ecological slope protection, can solve problems such as low plant survival rate and unreasonable substrate soil layer, and achieve the effects of reducing project cost, resisting rain erosion, and preventing substrate loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

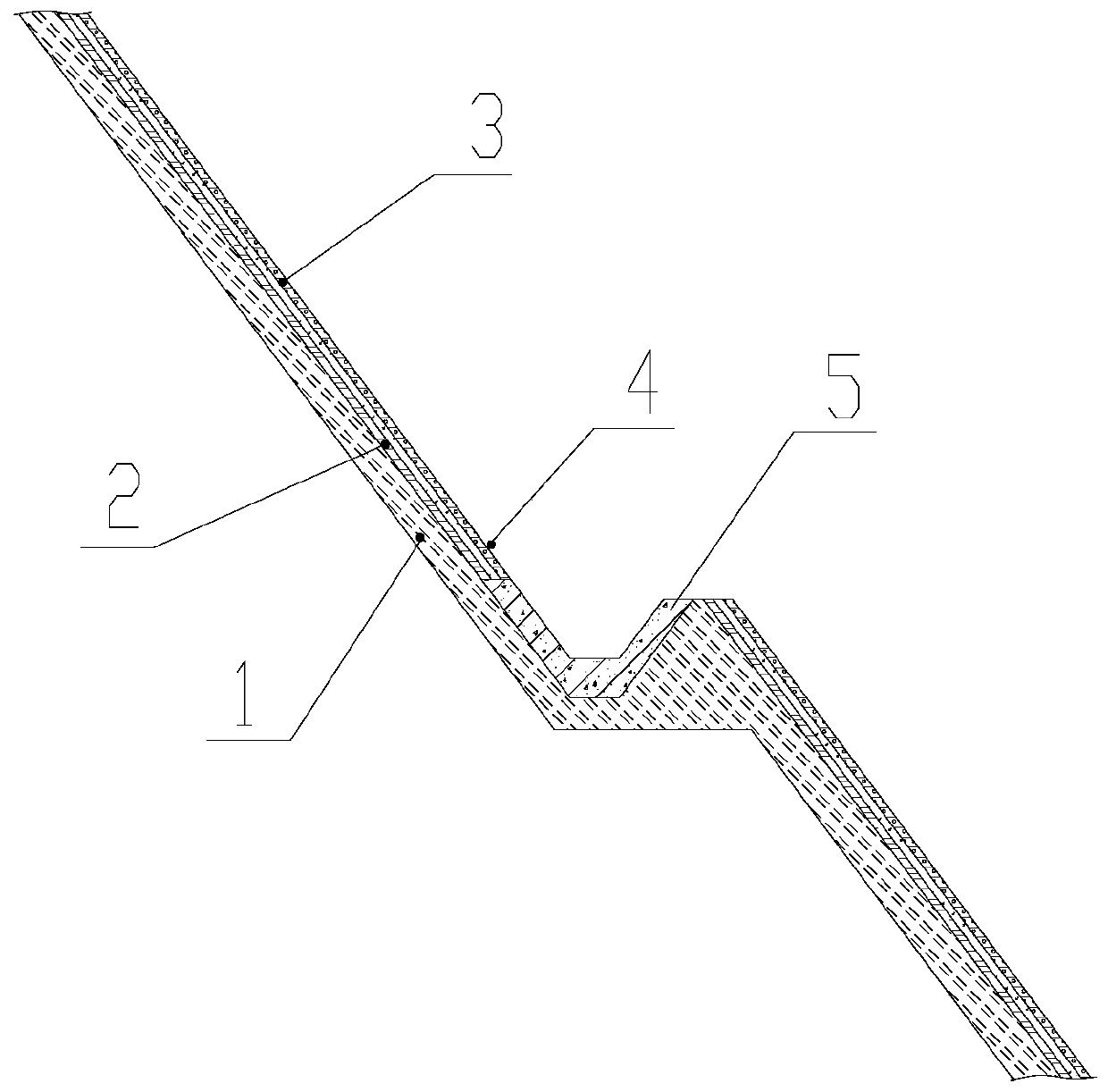

[0055] Example 1: At the beginning of April 2017, the following operations were carried out on the rock slope of the K7+365-K7+727.6 section of the road connecting the upper and lower reservoirs of the Jinzhai Pumped Storage Power Station in Anhui.

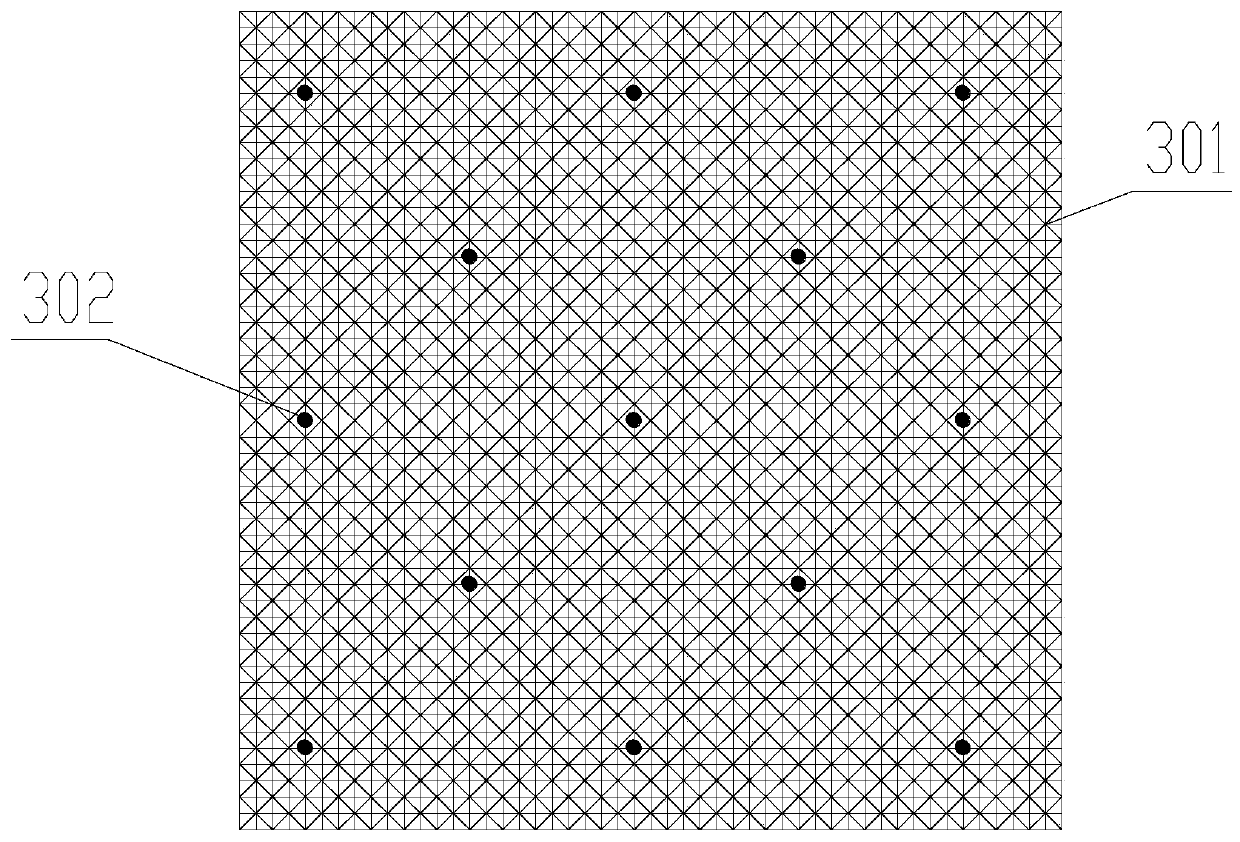

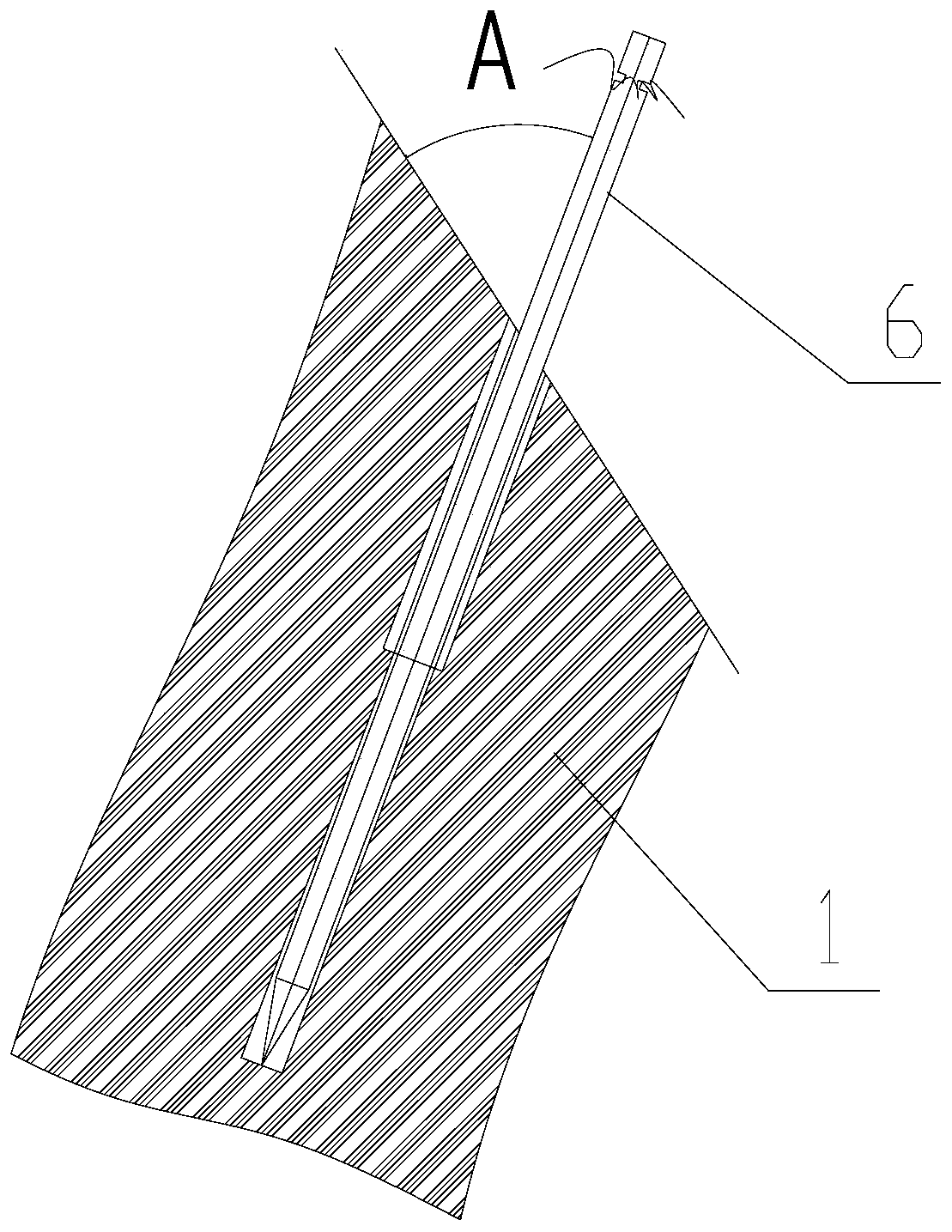

[0056] First, prepare multiple grids 301 made of degradable materials, the grid aperture (maximum size) is 50mm, and each grid has an area of (5*2)m 2 , a batch of 6 pile needles. Carry out operations on sunny days for more than 3 consecutive days in April, clean up the rock face, and divide the rock face up and down into three parts, with a height of 6 meters as a part. One side above the rock face leaves a height greater than the thickness of the solidified layer 2. Then drive the pile eye 302 by the prismatic apex position of 1 meter side length, the pile eye and the base surface just above the rock surface form an angle of about 60 degrees, and the pile eye diameter is 30mm.

[0057] Then the grid is fixed along the rock f...

Embodiment 2

[0065] Embodiment 2: In March 2018, the following operations were carried out on the rock slope of the upper and lower reservoirs of the Jinzhai Pumped Storage Power Station in Anhui Province.

[0066] (1) Prepare a grid 301 made of degradable materials, with a mesh size of 80*80 (mm), and each sheet has an area of (6*1.8)m 2 , a batch of pile needles 6, the tails of the pile needles all have groove fixing parts for binding the grid 301 ropes.

[0067] (2) Choose a sunny day in March to clean up the rock face and piling hole 302. The pile holes 302 are opened on a substantially flat rock surface, and the points of the pile holes 302 are arranged in a rib shape. When driving the pile holes, keep the pile holes and the base surface directly above the rock surface at an angle of 60 degrees. The diameter of the pile holes is 50mm, and the depth is 100mm.

[0068] (3) The grid is fixed along the rock surface by pile needles.

[0069] (4) 100% base soil by mass percentage is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com