An automatic system for aircraft rudder ray detection

An automated system and radiographic detection technology, applied in the direction of using radiation to analyze materials, analyze materials, instruments, etc., can solve problems such as low efficiency in the detection process, and achieve the effects of avoiding radiation safety risks, improving work efficiency, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

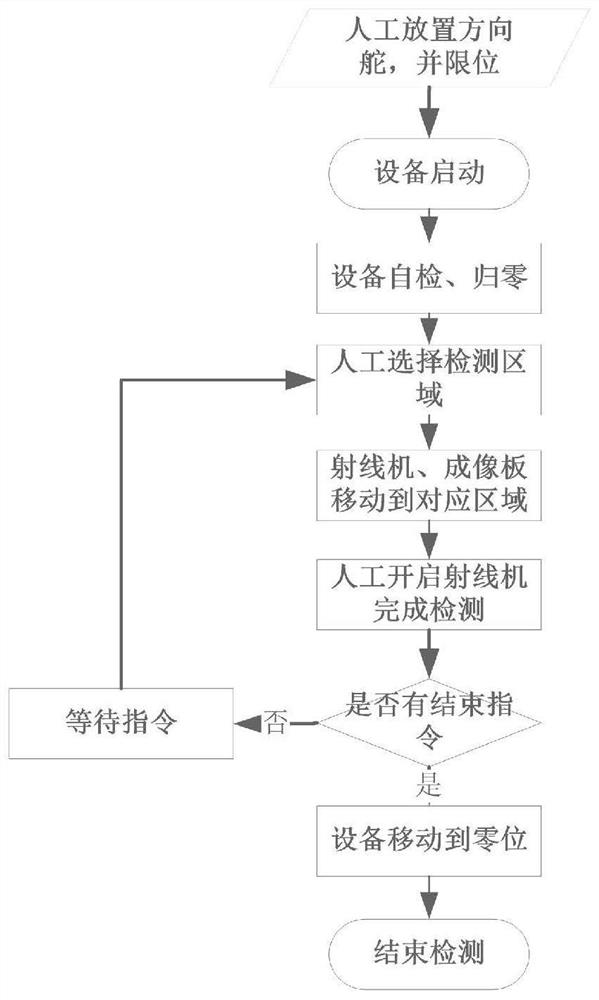

[0026] In order to make the technical means, creation features, achievement goals and effects of the present invention easy to understand and understand, the present invention is further described below with reference to the accompanying drawings and embodiments.

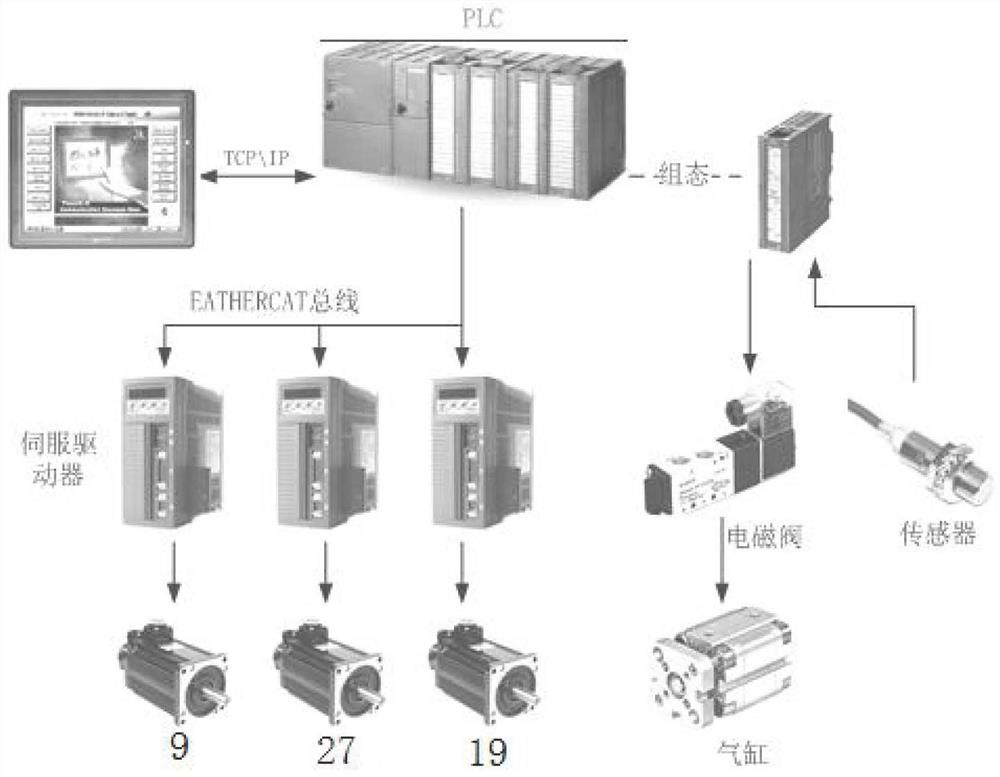

[0027] like figure 2 and Figure 4 As shown, an aircraft rudder ray detection automation system is mainly composed of three parts: the main control system, the equipment body and the monitoring system.

[0028] The main control system is used to control the entire action process of the equipment body, including a remote console with a PLC control system; the equipment body is used for workpiece support and detection components, and the equipment body includes equipment brackets 1. A support device, a ray machine device and an imaging plate device arranged on the equipment support 1; the monitoring system includes a monitoring camera and an operating room observation screen.

[0029] Specifically, since there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com