Vibration damping device of inverted structure

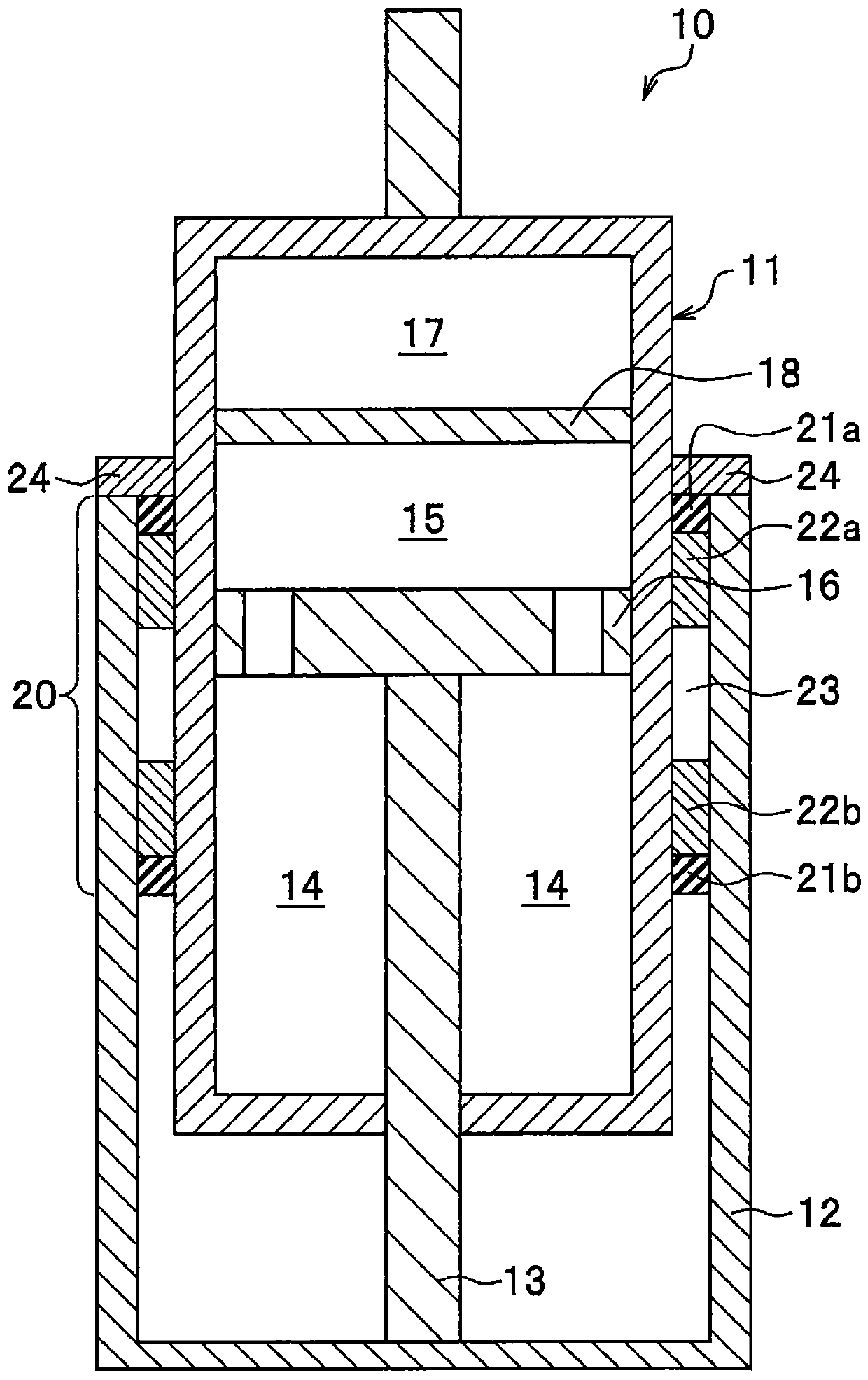

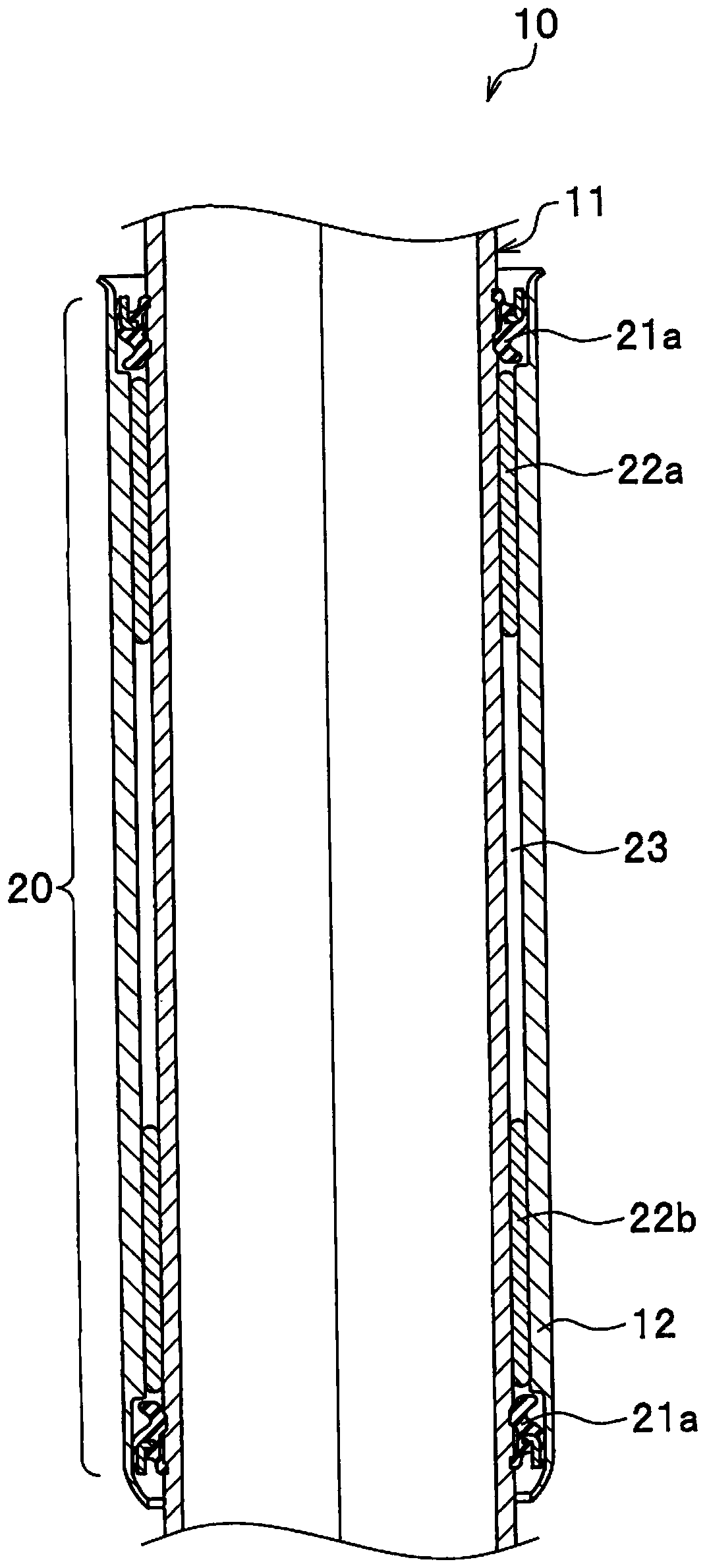

一种振动衰减、构造的技术,应用在减振器、减震器、液体减振器等方向,能够解决油易热膨胀、气体室反弹力上升、车辆高度变化等问题,达到低摩擦性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

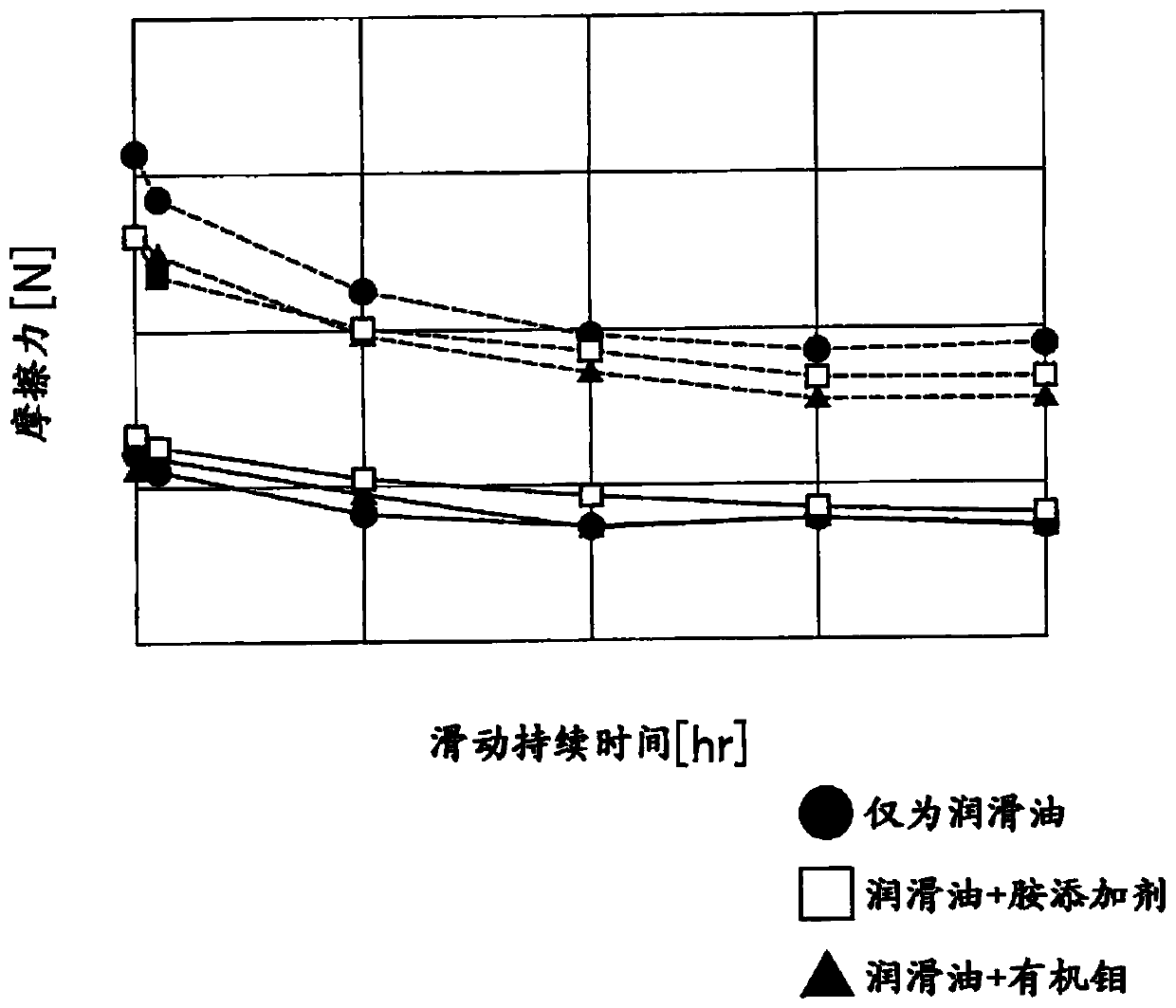

[0104] For the vibration attenuation device of the inverted structure of Example 1, a sleeve containing 85% by mass of polytetrafluoroethylene and 15% by mass of perfluoroalkoxyalkane (PFA) was used as a sleeve, and it was used as a lubricating oil in an existing damper. 1000ppm molybdenum dithiocarbamate (MoDTC) is added to the shock oil.

[0105] The sleeve is formed in a substantially cylindrical shape with an inner diameter of 40 mm, an outer diameter of 44 mm, and a height of 20 mm. In addition, the distance between the sleeves of the vibration damping device was 115 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com