Ratchet feeding mechanism of cable tie tool

A feeding mechanism and ratchet technology, which is applied in the field of ratchet feeding mechanism, can solve problems such as error-prone, low efficiency, and deformation of bulk cable ties, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

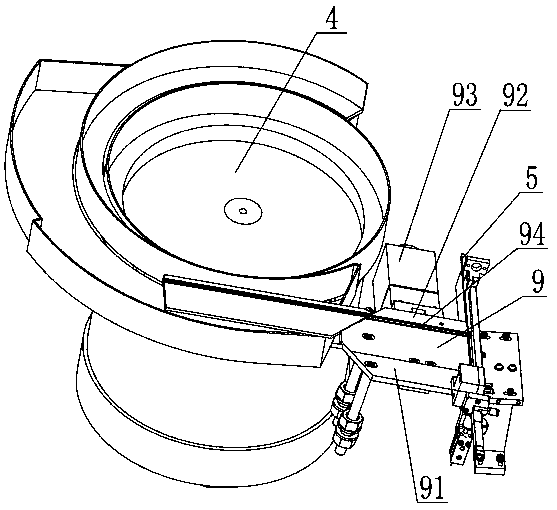

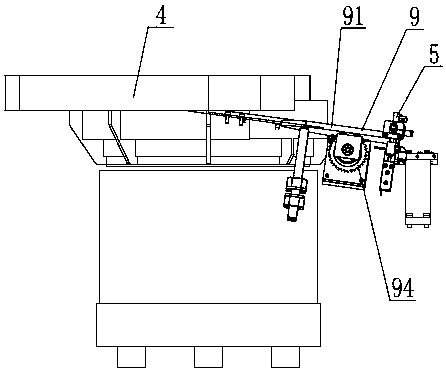

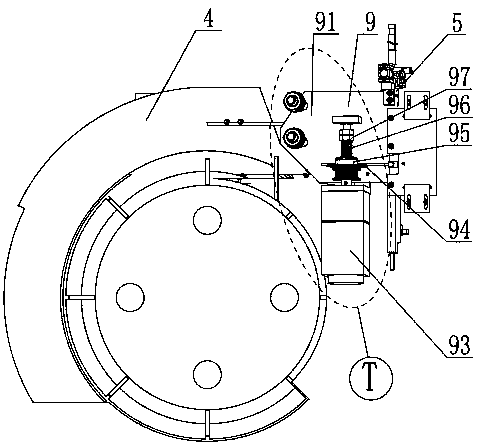

[0018] Such as figure 1 , figure 2 ,and image 3 As shown, the circular vibrating plate 4 can organize, screen, sort, orientate the messy and disorderly bulk cable ties and output the cable ties in a unique orientation. The output port of the circular vibrating plate 4 is a linear guide rail, so The linear output guide rail of the circular vibrating plate 4 is mainly used to limit the head of the cable tie, that is, the output guide rail of the circular vibrating plate 4 is to guide the head of the cable tie. In order to avoid the linear output guide rail of the circular vibrating plate 4 being too long, a ratchet drive system 9 is added between the circular vibrating plate 4 and the material distribution mechanism 5 so as to improve the stability of cable tie conveying. The ratchet drive system 9 is the subject of the present invention: a ratchet feeding mechanism for a cable tie tool.

Embodiment 2

[0020] Such as figure 1 , figure 2 ,and image 3 As shown, a ratchet feeding mechanism of a cable tie tool includes: a cable tie conveying plate 91, a pressure plate 92, a motor 93, a clutch spring 96, a torque adjustment nut 97, a friction clutch 95, a ratchet wheel 94, the motor 93, clutch Spring 96, torque adjusting nut 97, friction clutch 95 and ratchet 94 are coaxially installed and fixed below the cable tie conveying plate 91. The cable tie conveying plate 91 has a groove according to the size of the cable tie head. In the groove of the strap conveying plate 91, the binder plate 92 is fixed above the groove of the strap conveying plate 91, the ratchet 94 is located at the bottom of the groove of the strap conveying plate 91 and the ratchet of the ratchet 94 The bottom surface of the groove of the cable tie conveying plate 91 is exposed, the torque of the motor 93 is transmitted to the ratchet 94 through the friction clutch 95, and the ratchet 94 rotates to push the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com