Reference adjusting device for aero-engine compressor drum runout measurement

An aero-engine and adjustment device technology, applied in mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problems of the drum axis not being completely coincident, the measurement error is large, etc., to facilitate management, use and maintenance, and reduce maintenance. Cost, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

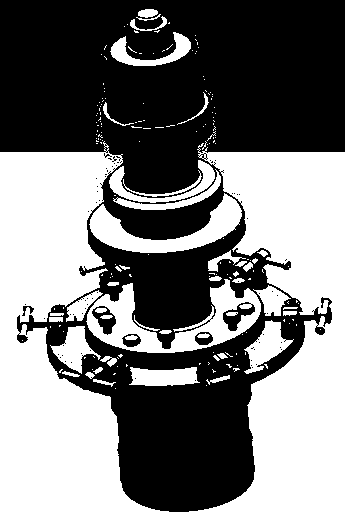

Image

Examples

Embodiment 1

[0020] Embodiment 1: a kind of reference adjustment device of aero-engine compressor drum runout measurement, it comprises the following steps when it is used:

[0021] S1, the engine compressor drum is installed on the measurement platform 4;

[0022] S2. Use a dial indicator to detect the runout value of the upper and lower end faces of the drum;

[0023] S3. If the runout of the upper end surface is large (≥0.01mm), it means that the installation of the drum is inclined, then use a wrench to adjust the adjustment screw 5 at the corresponding position, so that the runout of the upper end surface is not greater than 0.01mm.

Embodiment 2

[0024] Embodiment 2: a kind of reference adjustment device of aero-engine compressor drum runout measurement, it comprises the following steps when it is used:

[0025] S1, the engine compressor drum is installed on the measurement platform 4;

[0026] S2. Use a dial indicator to detect the runout value of the upper and lower end faces of the drum;

[0027] S3. If the runout of the lower end surface is large (≥0.03mm), it means that the installation of the drum is inclined, then use a wrench to adjust the adjustment screw 5 at the corresponding position, so that the runout of the lower end surface is not greater than 0.03mm.

Embodiment 3

[0028] Embodiment 3: a kind of reference adjustment device of aero-engine compressor drum beat measurement, it comprises the following steps when it is used:

[0029] S1, the engine compressor drum is installed on the measurement platform 4;

[0030] S2. Use a dial indicator to detect the runout value of the upper and lower end faces of the drum;

[0031] S3. If the runout of the upper and lower end surfaces is large (upper end surface ≥ 0.01mm, lower end surface ≥ 0.03mm), it means that the axis of the drum is parallel to the axis of the measuring device, but they do not overlap. Then use a wrench to adjust the adjustment screw 5 at the corresponding position, so that the axis of the drum coincides with the measuring device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com