set8 lysine methyltransferase inhibitor and its intermediate, preparation method and use

A lysine methyltransferase technology, applied in the field of SET8 lysine methyltransferase inhibitors and intermediates thereof, in the field of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

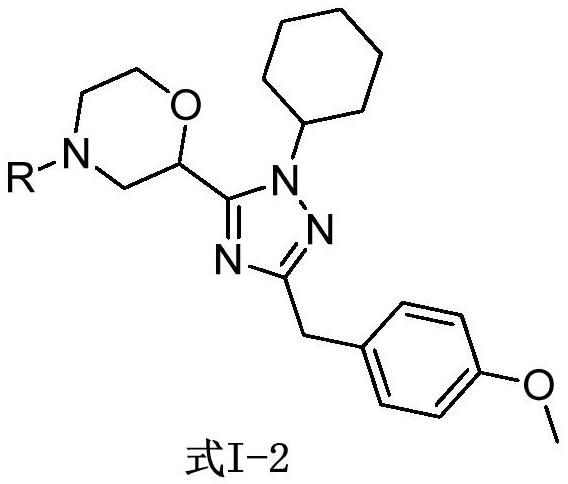

AI Technical Summary

Problems solved by technology

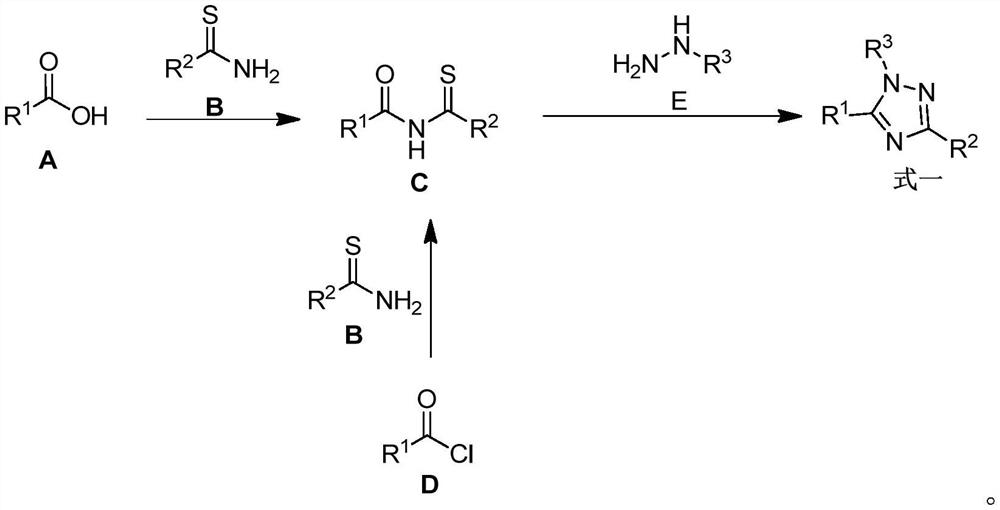

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Preparation of tert-butyl 2-((2-(4-methoxyphenyl)thioacetyl)carbamoyl)morpholine-4-carboxylate (Formula II)

[0046]

[0047] The raw materials 4-(tert-butoxycarbonyl)morpholine-2-carboxylic acid (1.0 mmol, 231 mg), 2-(7-oxybenzotriazole)-N,N,N',N'-tetramethyl urea hexafluorophosphate (HATU, 1.1 mmol, 418 mg) was dissolved in 4 mL of dry dichloromethane, under nitrogen protection, and stirred at room temperature for 20 minutes, then the raw material 2-(4-methoxyphenyl) was added to the above system. ) thioacetamide (1.1 mmol, 199 mg), after continuing to stir for 1 hour, N,N-diisopropylethylamine (DIEA, 1.1 mmol, 142 mg) was added dropwise to the above reaction system, and continued under nitrogen protection at room temperature The reaction was stirred for 2 days. After the reaction solution was diluted with 50 mL of ethyl acetate, washed with 20 mL of water and saturated sodium chloride solution in turn, dried over anhydrous sodium sulfate, the reaction ...

Embodiment 2

[0048] Example 2 Preparation of tert-butyl 2-(1-cyclohexyl-3-(4-methoxybenzyl)-1H-1,2,4-triazol-5-yl)morpholine-4-carboxylate ( formula III)

[0049]

[0050] Formula II (0.16 mmol, 63 mg), cyclohexylhydrazine hydrochloride (0.2 mmol, 30 mg), and sodium acetate (0.36 mmol, 30 mg) were sequentially dissolved in a mixed solvent of 1 mL of acetic acid and 1 mL of 1,4-dioxane After that, it was sealed and then heated at 80°C until the II reaction was completed. After the reaction solution was diluted with 30 mL of ethyl acetate, washed with 20 mL of saturated sodium carbonate solution and saturated sodium chloride solution in turn, dried over anhydrous sodium sulfate, the reaction solution was concentrated, and separated by column chromatography [V (petroleum ether): V ( ethyl acetate) = 3:1-1:1] to obtain 40 mg of pale yellow oil III in a yield of 55%.

Embodiment 3

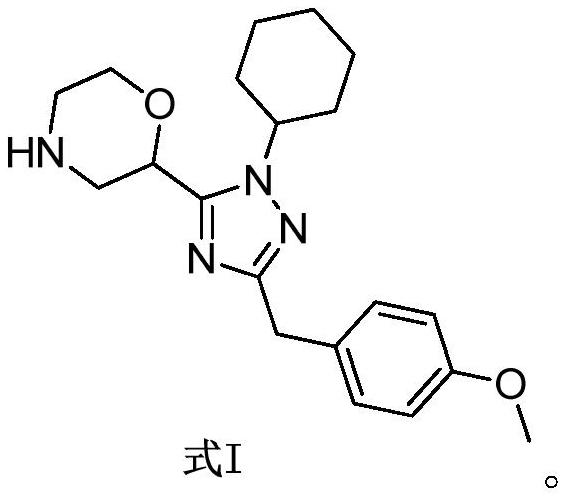

[0051] Example 3 Preparation of 2-(1-cyclohexyl-3-(4-methoxybenzyl)-1H-1,2,4-triazol-5-yl)morpholine (Formula I)

[0052] Formula III (0.09 mmol, 41 mg), anisole (0.1 mmol, 11 mg), and 0.5 mL of hydrogen chloride in 1,4-dioxane solution (4M) were dissolved in 3 mL of dichloromethane in turn, and the reaction was sealed for 3 days. , until the III reaction is complete. The reaction solution was evaporated to dryness to obtain a yellow oil, which was diluted with 30 mL of ethyl acetate, washed with 20 mL of saturated sodium carbonate solution, and dried over anhydrous sodium sulfate. Chloromethane solution):V(methanol)=25:1-20:1], 26 mg of yellow oil I was obtained, the yield was 81%.

[0053] 1 H NMR (400MHz, CDCl 3 ):δ7.25-7.23(m,2H),6.82-6.80(m,2H),4.67-4.64(m,2H),4.28-4.21(m,2H),3.98(s,2H),3.85-3.79 (m,1H),3.77(s,3H),3.73-3.67(m,1H),3.31-3.25(m,1H),3.19-3.15(m,1H),3.01-2.87(m,2H),1.98 -2.85(m,6H),1.73-1.70(m,1H),1.40-1.26(m,4H). 13 C NMR (400MHz, CDCl3): δ161.8, 158.1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com