Adhesive storage tank with heat exchange device

A technology of heat exchange devices and adhesives, applied in the direction of tank cars, packaging, transportation and packaging, etc., can solve the problems of limited effect, unable to assist in improving cooling time and efficiency, so as to improve cooling efficiency and effect, and speed up subsequent processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

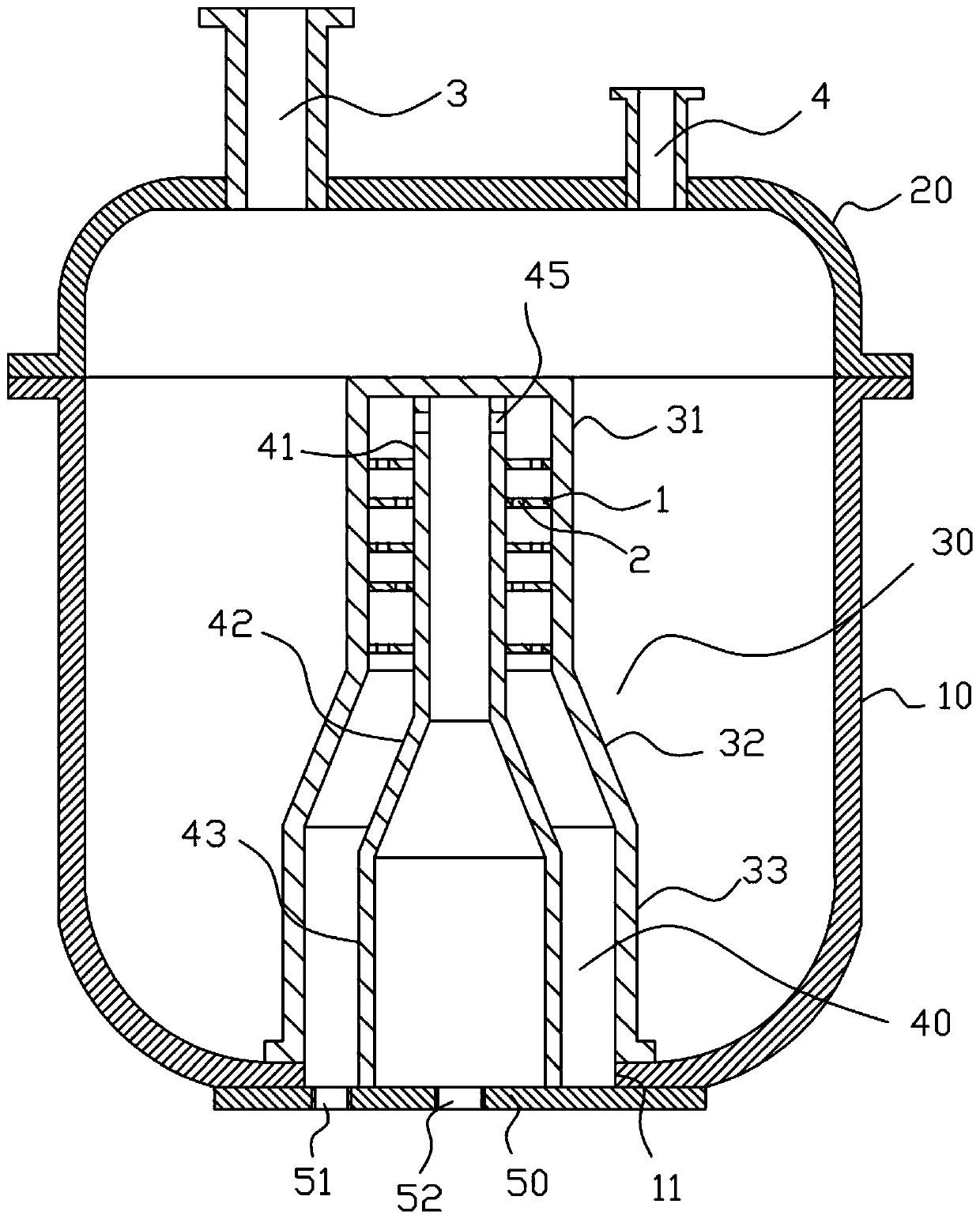

[0018] Example: see Figure 1 to Figure 2 As shown, an adhesive storage tank with a heat exchange device includes a main tank body 10 and a tank cover 20, and the tank cover 20 is closed on the top surface of the main tank body 10;

[0019] The middle part of the bottom plate of the main tank body 10 is formed with a middle through hole 11, and the middle top surface of the bottom plate of the main tank body 10 is fixed with a main heat exchange sleeve 30, and the bottom of the main heat exchange sleeve 30 communicates with the middle through hole 11. ;

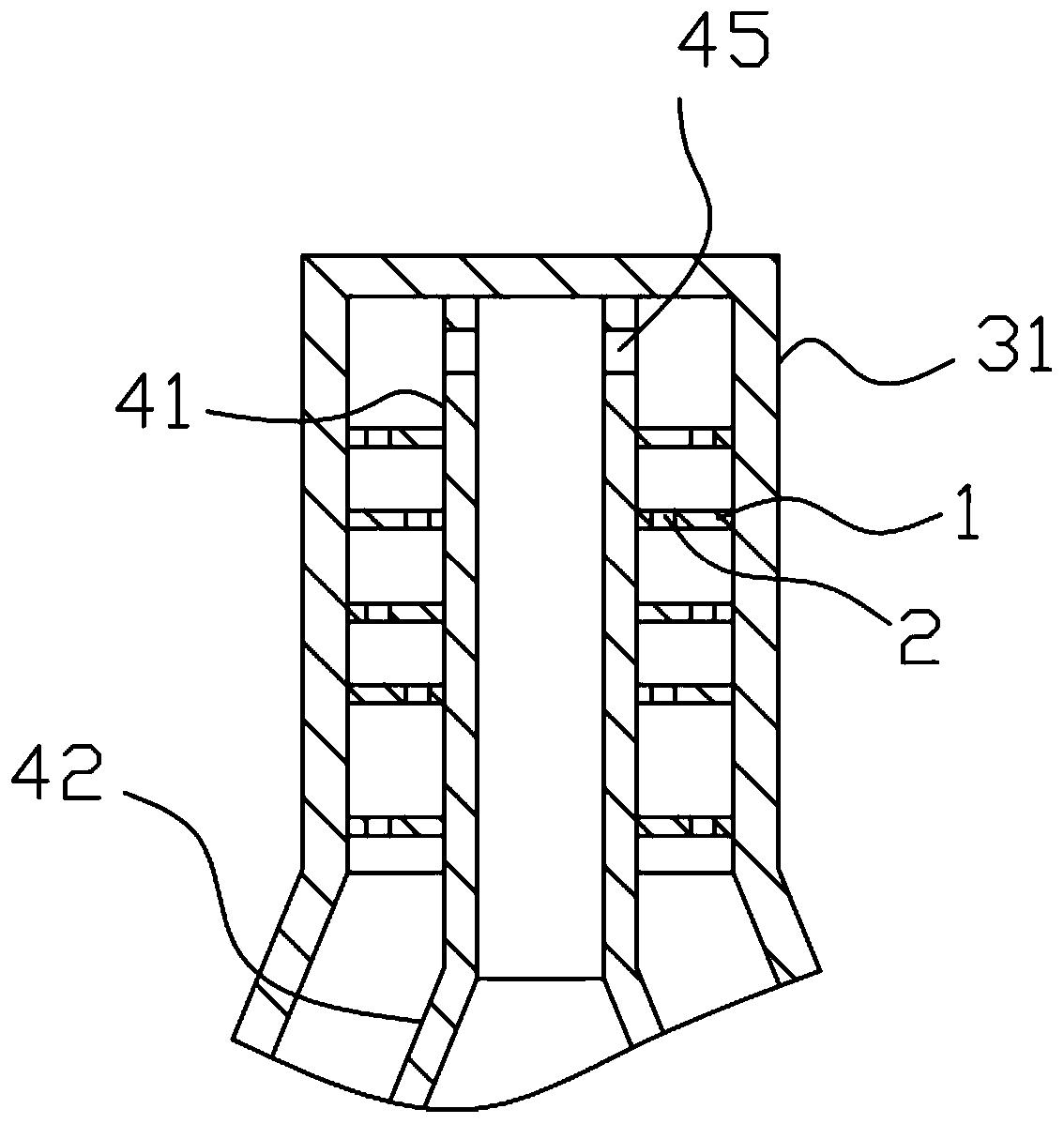

[0020] The inner sleeve 40 is fixed on the middle bottom surface of the top plate of the main heat exchange sleeve 30, the inner sleeve 40 is located in the main heat exchange sleeve 30, and the upper side wall of the inner sleeve 40 is formed with a radial through hole 45;

[0021] A bottom limiting plate 50 is fixed on the bottom surface of the bottom plate of the main tank body 10, the bottom limiting plate 50 covers the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com