Automatic register adjusting device of printing machine

A technology of adjusting device and printing machine, applied in printing machine, rotary printing machine, screen printing machine, etc., can solve the problems of low adjustment efficiency, time-consuming and laborious, low efficiency, etc., and achieve the effect of fast plate matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

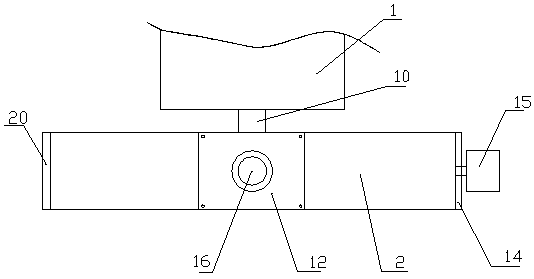

[0020] For the convenience of explanation, the following is combined with the Figure 1-5 , to explain in detail the invention of an automatic plate adjustment device for a printing machine.

[0021] The technical solution of the present invention is to provide the following automatic plate alignment adjustment device for a printing machine, including a screen frame fixing adjustment assembly for fixing the printing plate screen frame on the printing machine head 1, the screen frame fixing adjustment assembly It consists of an adjustment frame 2 for supporting and fixing the screen frame, and the inside of the adjustment frame 2 is provided with a motor, and the horizontal or / and longitudinal movement of the screen frame relative to the position of the machine head 1 can be realized by using the forward and reverse rotation of the motor; the motor Including a horizontal adjustment motor 3.1 or / and a longitudinal adjustment motor 3.2, the motor is located in the adjustment fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com