Method and device for measuring concentration of tobacco sheet pulp

A technology of tobacco sheet and measuring device, which is applied to the measuring device, and can solve the problems of lack of fast, accurate and efficient tobacco sheet slurry concentration measuring device and measuring method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

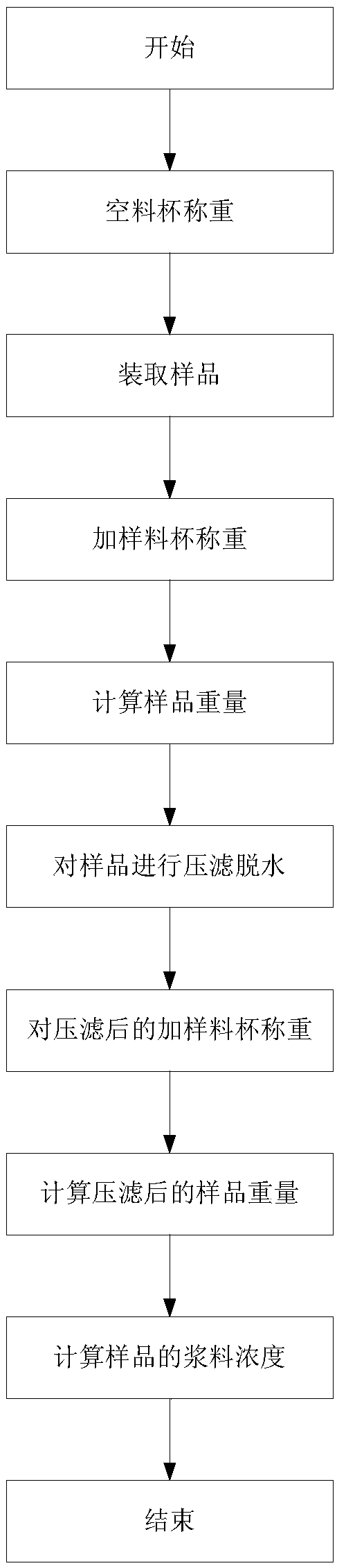

Method used

Image

Examples

Embodiment 1

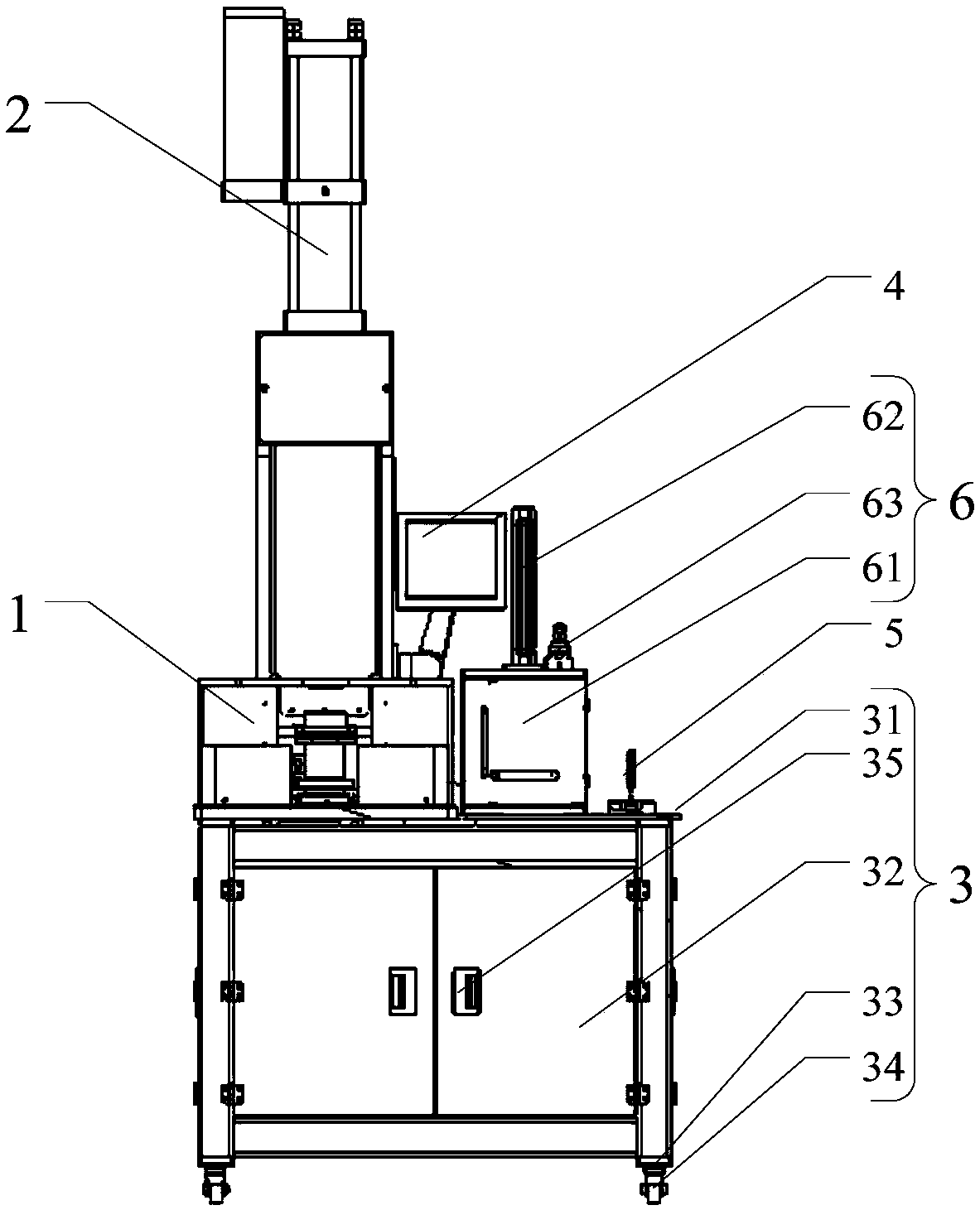

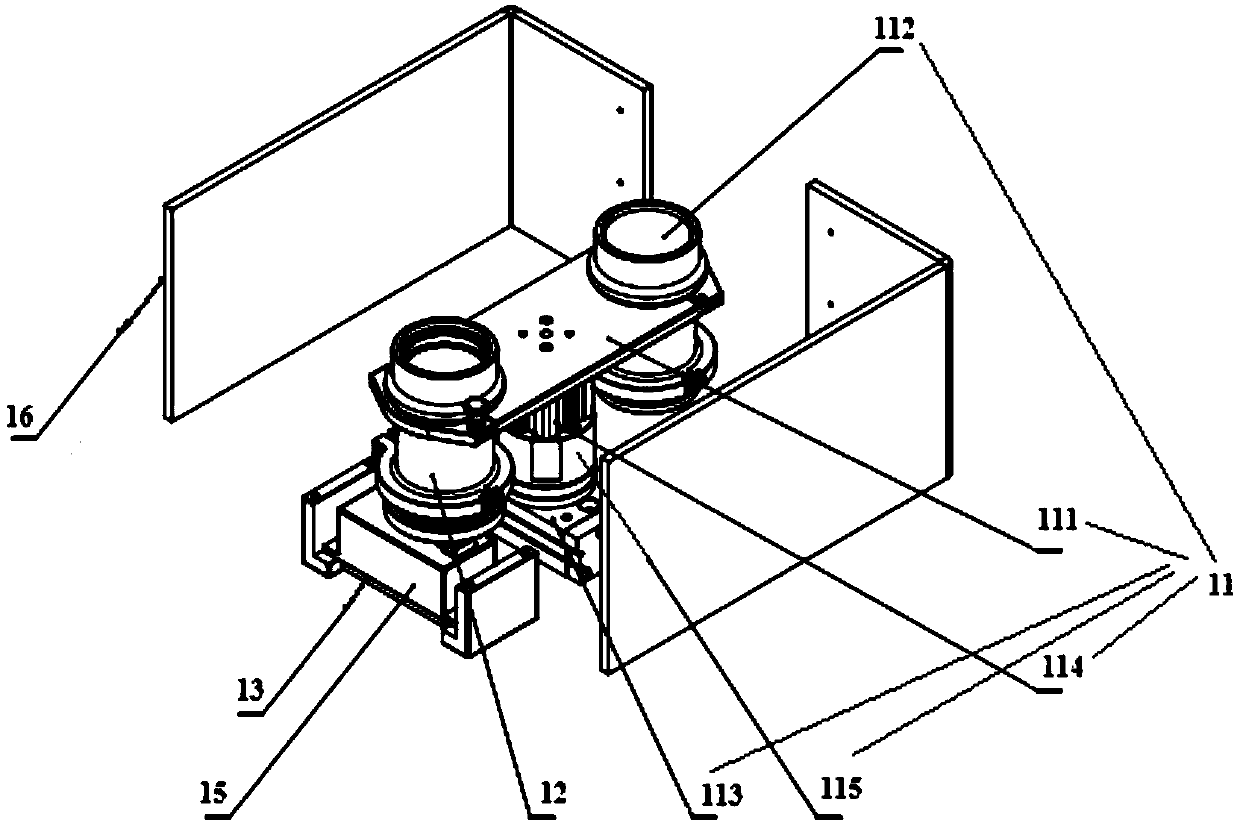

[0151] Initialize the measuring device for the concentration of tobacco sheet slurry, check whether the test components and filter press components are reset normally, whether there is a material cup left inside the movable platform, whether the waste liquid level in the waste liquid component exceeds the limit, and the pressure sensor and power switch. Whether the output is normal, whether the weighing balance is cleared, and whether the active platform is in the weighing station. After the measuring device is reset, everything is normal, and the measuring device will prompt "ready, ready to inject and measure" on the touch screen through the control part.

[0152] Open the safety cover, place an empty material cup on a rotating station of the movable plate of the movable platform, install a 600-mesh filter in the empty material cup, and cover the sealing piston pressure head, and send command signals to the control through the touch screen The control part sends a rotation s...

Embodiment 2

[0158] Take a certain amount of samples and divide them into 8 sub-samples, the weight of each sub-sample is M 0 , when the process value of the slurry concentration is 3.0%, the weight M after pressure filtration and dehydration is measured by this method. 1 , then these sub-samples are dried with an oven method to obtain the weight M after drying 2 , the correction coefficient A obtained by calculation is 0.471, and the specific data results are shown in Table 1.

[0159] Table 1

[0160]

[0161] Then, the oven method is used to obtain the weight M after drying 2 , and the slurry weight of the sub-sample is M 0 , through the slurry concentration W=M 2 / M 0 ×100%, the slurry concentration of the oven method was obtained by calculation. At the same time, the calculation formula of the correction coefficient A in the present invention is used to obtain the results of the slurry concentration. The specific results are shown in Table 2. It can be seen from Table 2 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com