Integrated automatic detection and material dividing device

A material dispensing device and automatic detection technology, applied in sorting and other directions, can solve the problems of material appearance, high efficiency, high precision, low quality, automation level, low weighing precision, complex structure, etc., and achieve obvious convenience and stability , simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

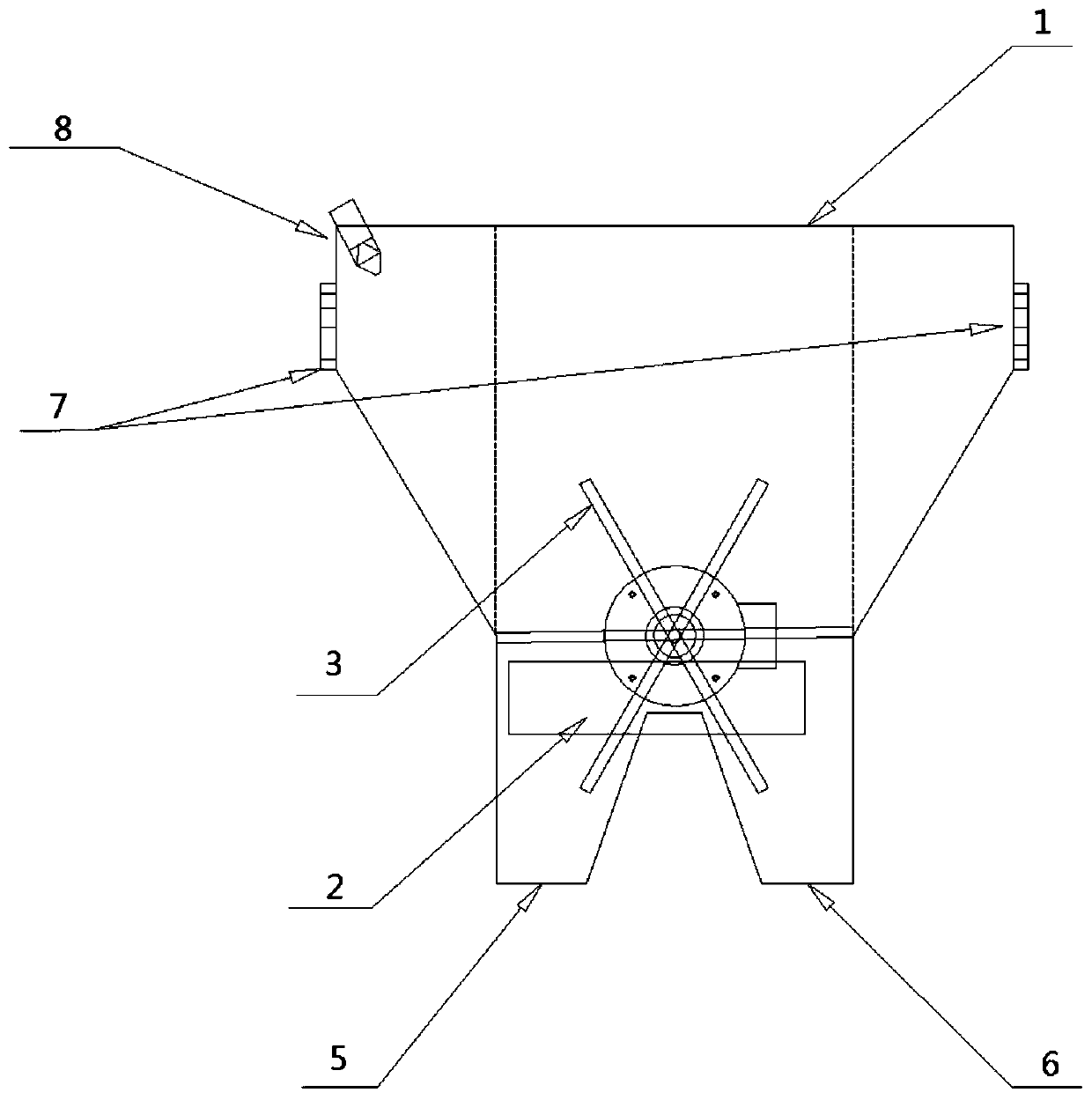

[0022] refer to figure 1 , figure 2 , an integrated automatic detection and distribution device, including a feeding mechanism 1, a feeding mechanism, a detection mechanism, a material distribution mechanism 3 and a control mechanism, the feeding mechanism 1 is built on the upper part of the feeding mechanism, which is convenient for gravity blanking .

[0023] The following, for the design of the detection mechanism and the material distribution mechanism, includes but is not limited to:

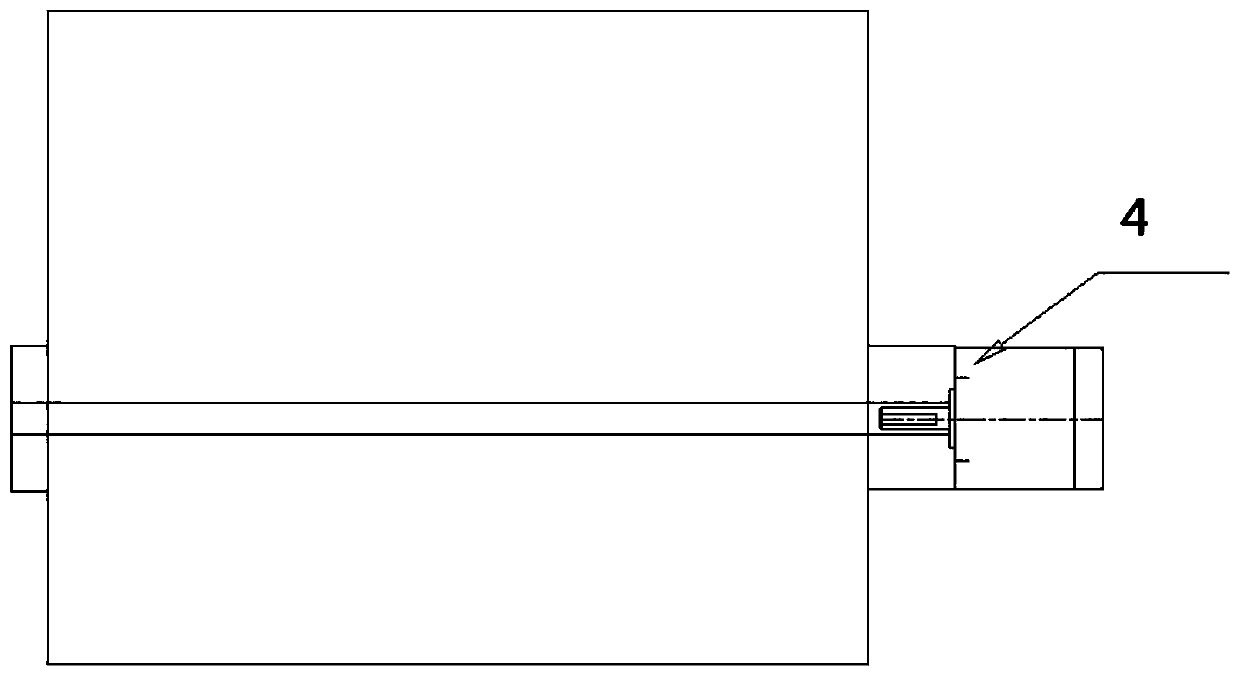

[0024] The detection mechanism is a weighing mechanism (2), the weighing mechanism (2) includes a weighing pan, the weighing pan is also provided with a load cell, the material distribution mechanism (3) includes a turning plate, The turning plate is connected with the motor (4) through a coupling, the turning plate is fixedly mounted on the weighing pan, and the weighing mechanism (2) and the material distribution mechanism (3) are integrated , and are jointly installed at the feeding ...

Embodiment 2

[0032] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that the detection mechanism is a visual sensor 8, and the visual sensor 8 is installed on the feeding mechanism 1, and the visual sensor 8 is connected with the control The electrical connection of the device is aimed at the situation that the weight is not used as the deviation value. The visual sensor 8 of the present embodiment 2 can be selected to accurately distinguish the feed.

Embodiment 3

[0034] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that the detection mechanism is a photoelectric fiber sensor 7, and the photoelectric fiber sensor 7 is installed in the feeding mechanism 1, and the photoelectric fiber sensor 7 and The electrical connection of the controller is designed to face complex materials, and it is a new detection method that can be selected when the weighing mechanism 2 or the visual sensor cannot achieve accurate results, and aims to provide more accurate material detection and distribution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com