Spring external type perfume pump structure

An external type, perfume technology, applied in the types of packaging items, applications, special packaging items, etc., can solve the problems of complex installation process, slow air pump speed, poor spray effect, etc., to achieve stable product quality, fast pumping speed, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

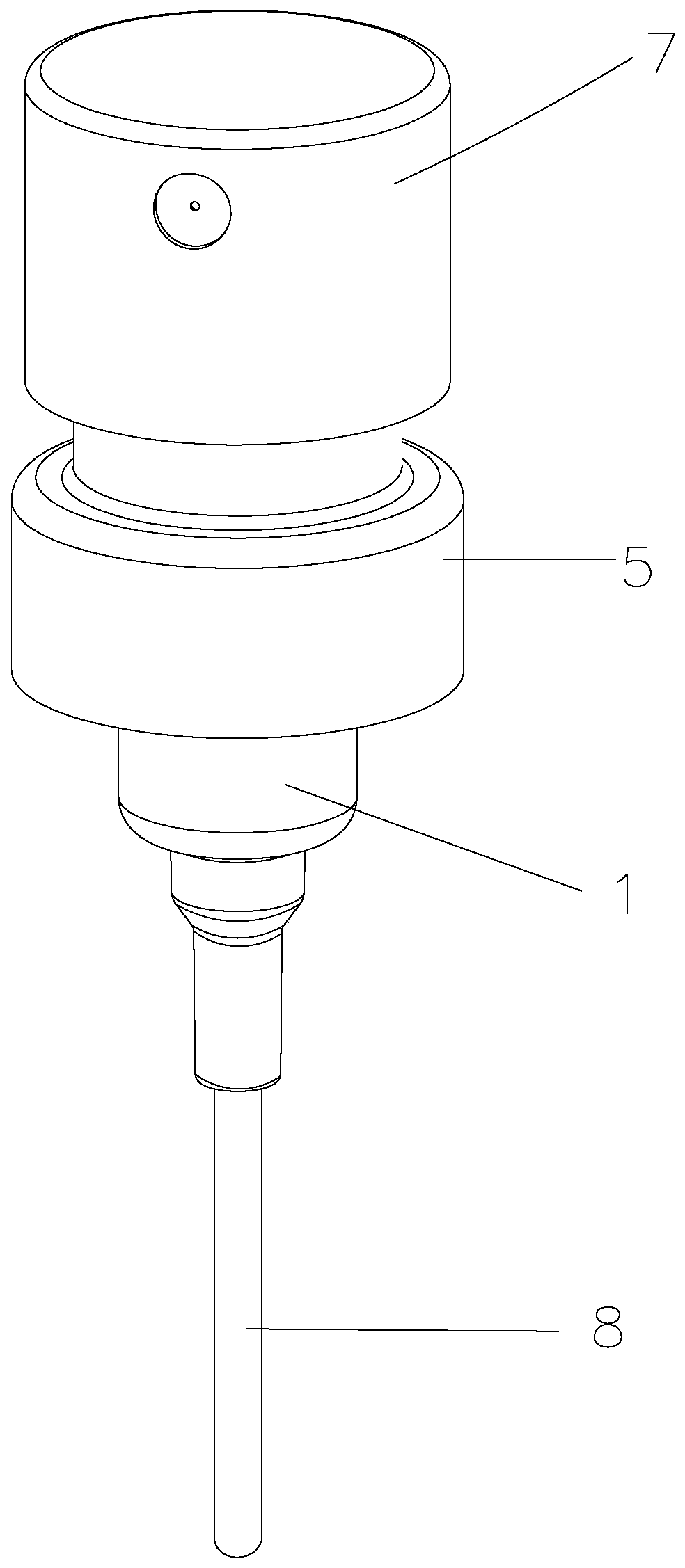

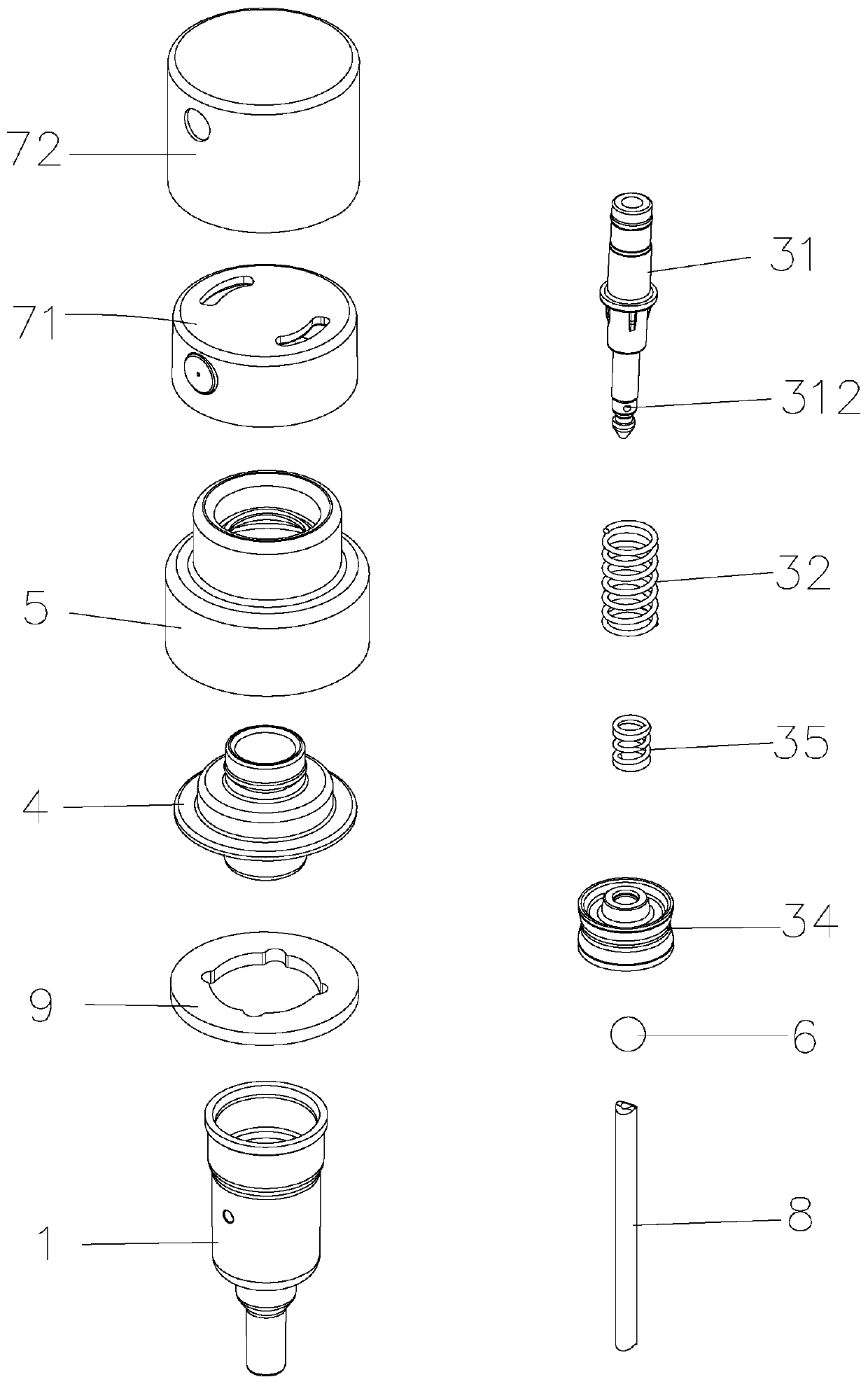

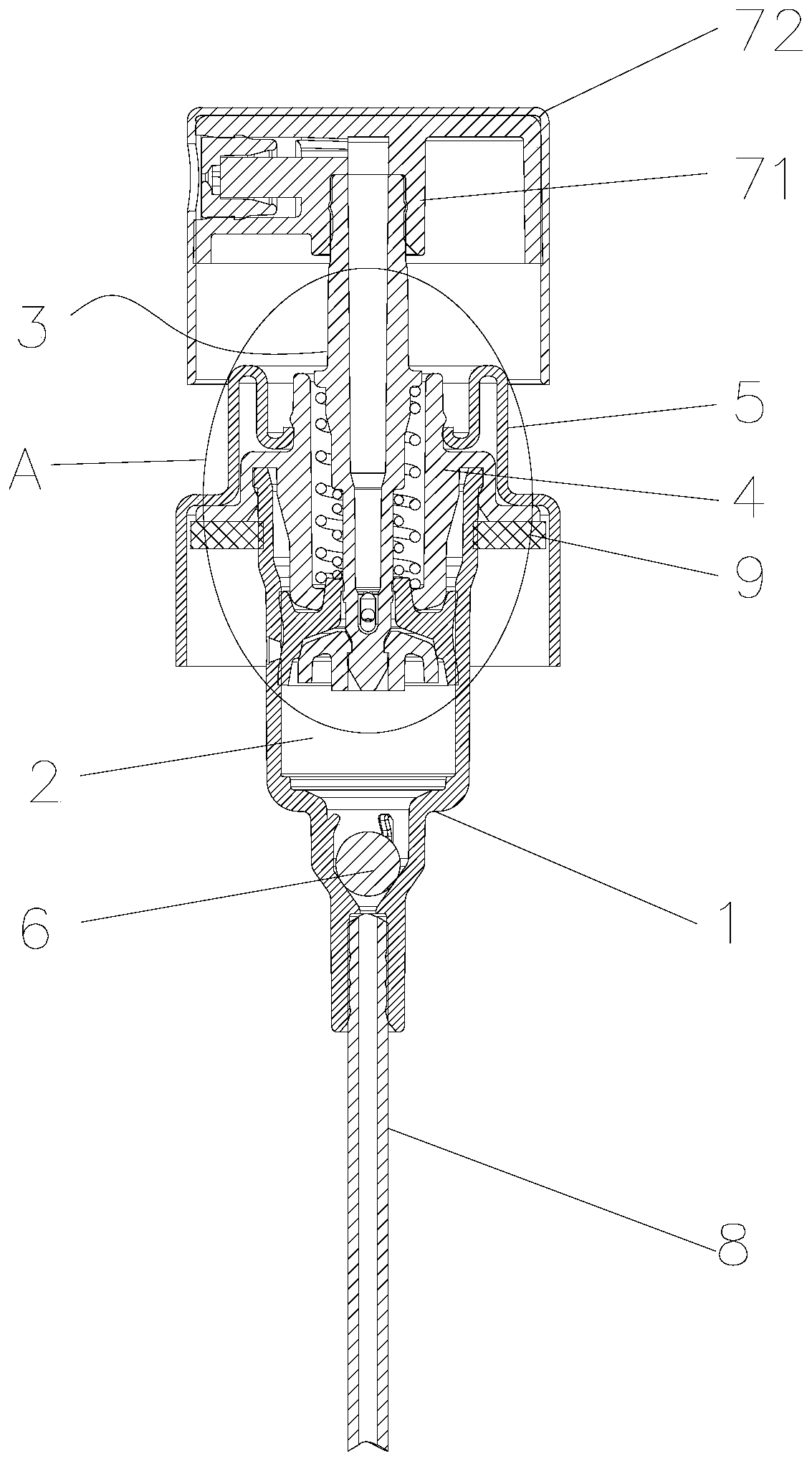

[0026] Such as Figure 1 to Figure 5 As shown, a spring external type perfume pump structure includes a pump body 1 that extends into the bottle body. The pump body 1 is provided with a pump chamber 2, and the pump chamber 2 is provided with a device that can move up and down in the pump chamber. The liquid in the bottle is pumped upwards by a suction assembly 3. The pump body 1 and the upper end of the pump chamber 2 are connected with a locking cover 4 that can prevent the suction assembly 3 from coming out of the pump chamber 2. The lock The tight cap 4 is connected with an aluminum oxide bayonet 5 that can be fixed to the bottle; the lower end of the pump chamber 2 is provided with a one-way valve 6 that only allows the liquid in the bottle to discharge upward when the suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com