Central actuator for a hydraulic or pneumatic clutch actuation

A technology of pneumatic clutches and actuators, applied in the direction of fluid-driven clutches, non-mechanical-driven clutches, clutches, etc., can solve the problems of not so fast cooling and hardening, long residence time, etc., and achieve small dependence on dimensional tolerances and strengthen effect and dimensional stability, avoiding harmful structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

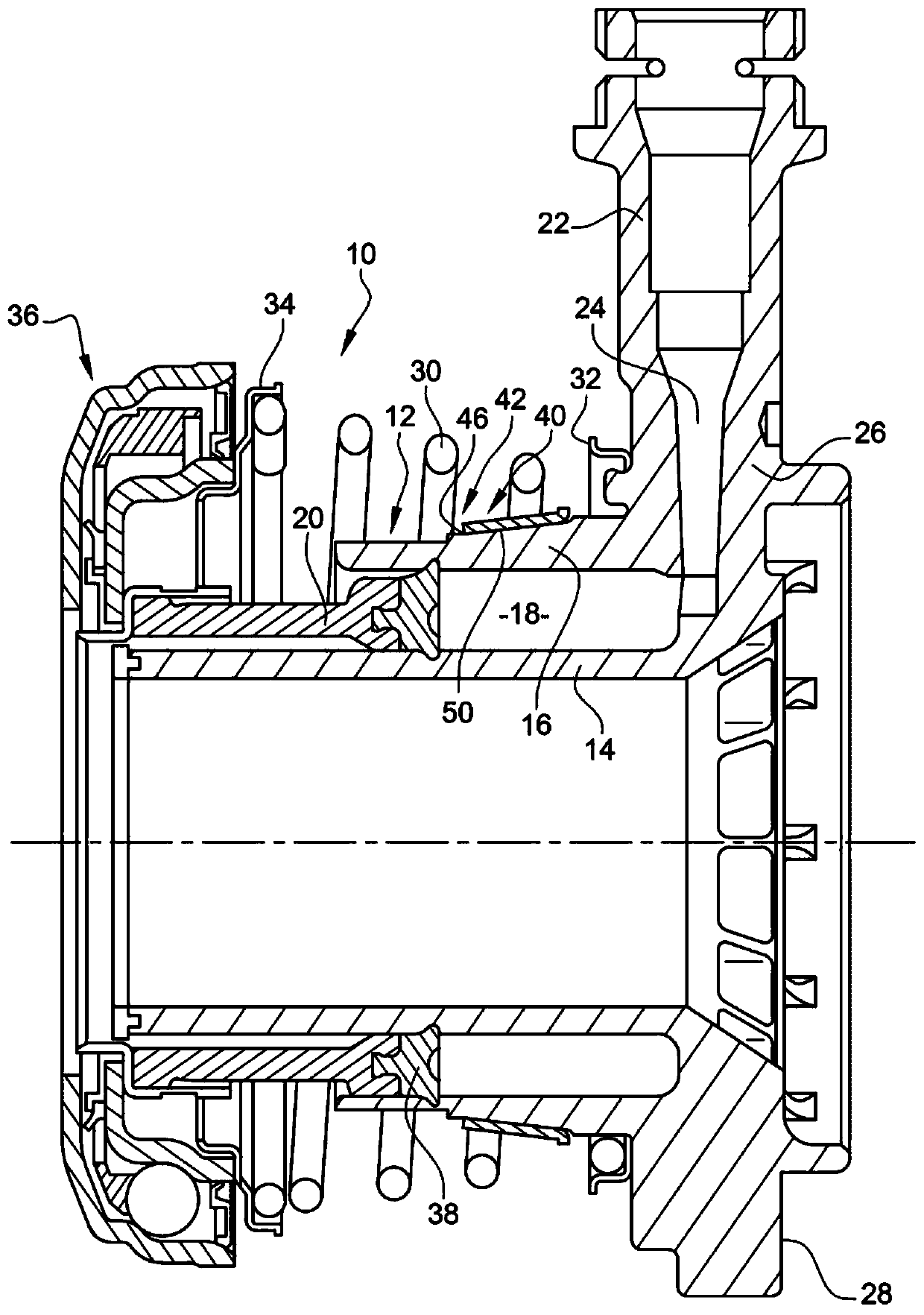

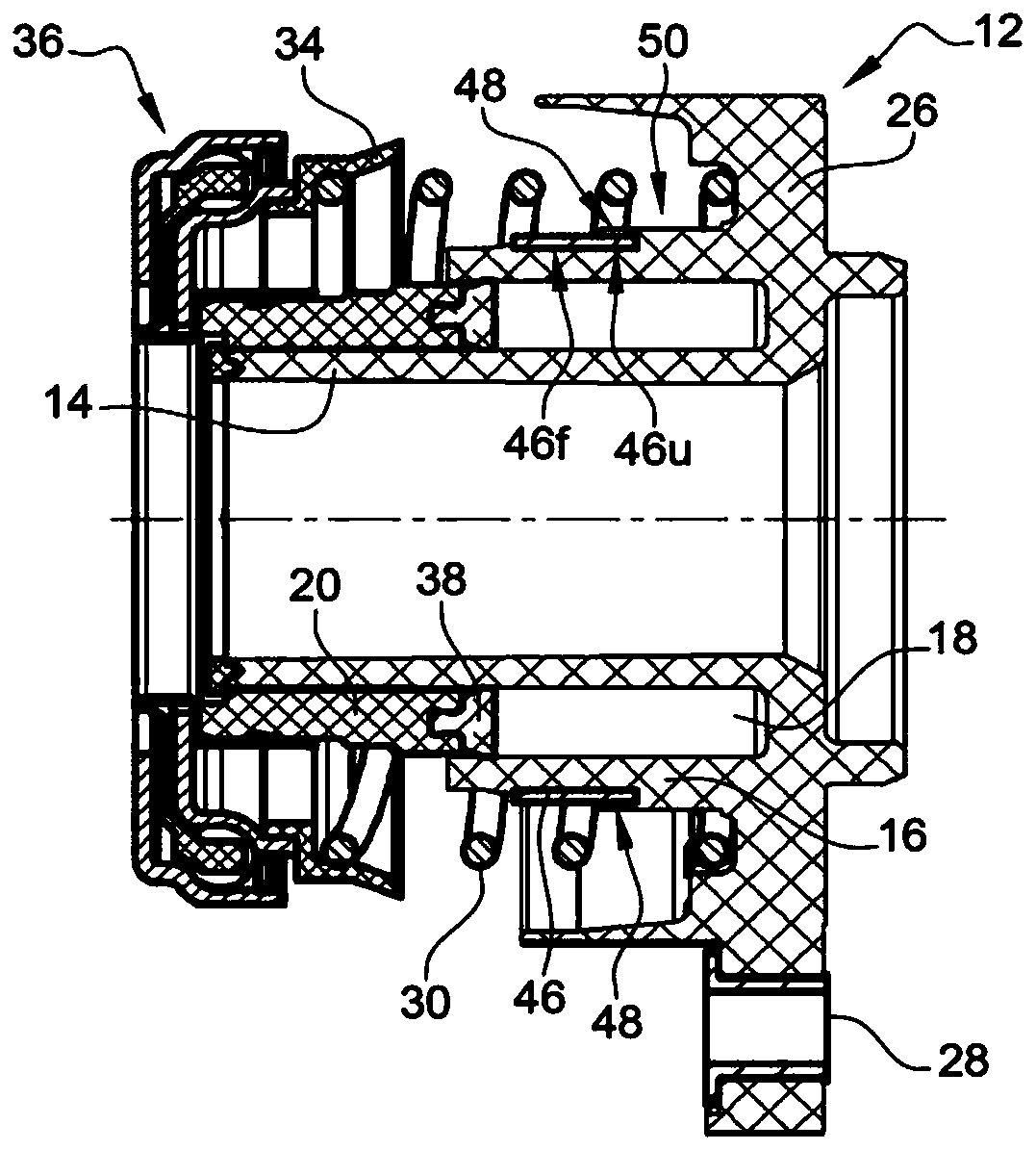

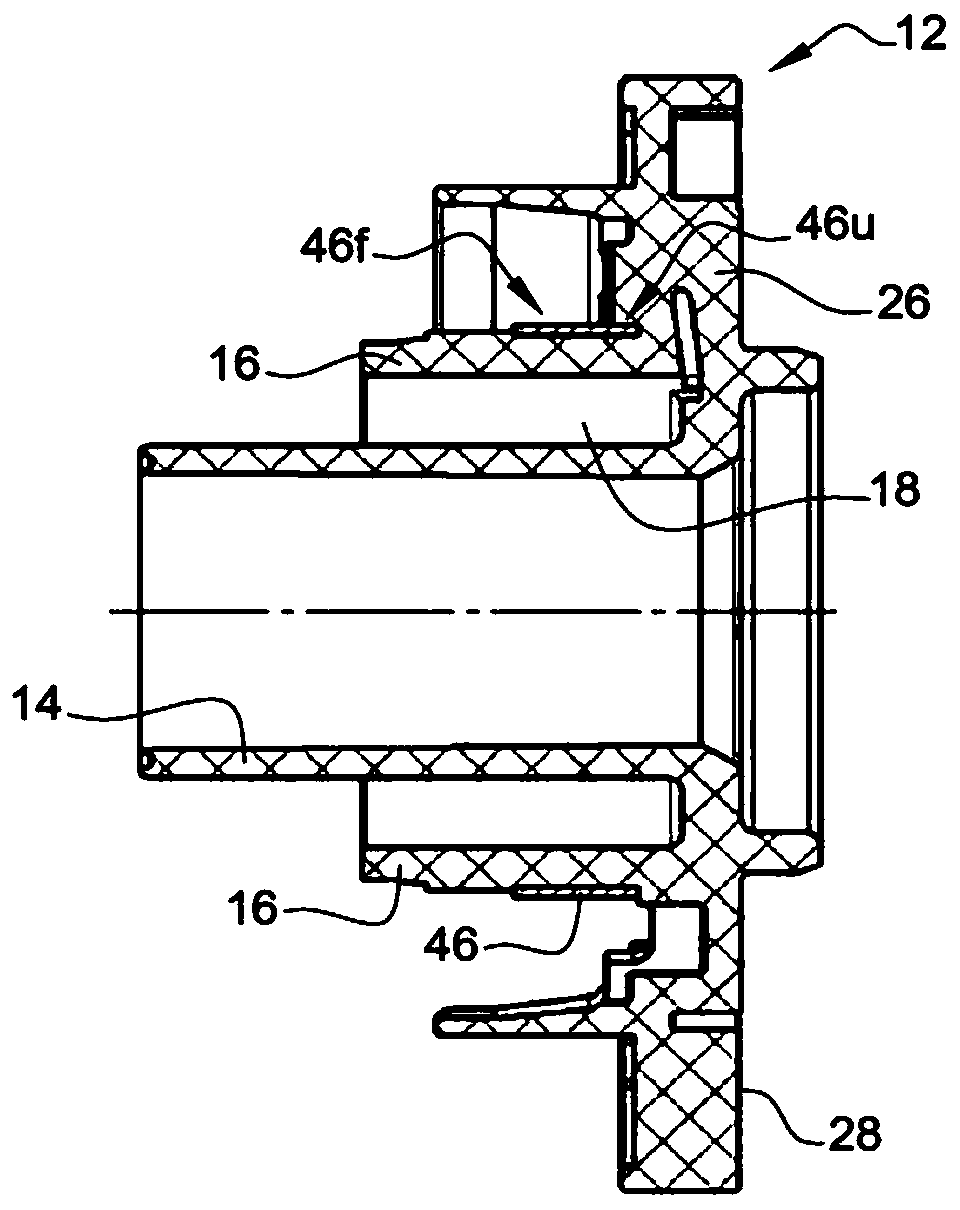

[0037] figure 1 The central release mechanism 10 for hydraulic clutch actuation of a dry friction clutch is shown in a dismounted state in a basic position. The central release mechanism 10 has an injection molded cylinder housing 12 made of plastic, such as GF-filled polyphthalamide, which has two concentrically arranged cylinder walls, an inner cylinder wall 14 and an outer cylinder wall 16, which An annular pressure chamber 18 is defined. An annular piston 20 , which can be operably connected to a clutch (not shown), is movably received in the pressure chamber 18 in the axial direction, which annular piston is optionally exposed to pressure via a pressure connection fitting 22 of the cylinder housing 12 . Medium, so that the friction clutch is disengaged by the movement of the annular piston 20. To this end, the pressure connection fitting 22 is connected to the pressure chamber 18 via a channel 24 formed in the cylinder housing 12 , so that the pressure medium, ie hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com