Spiral wound membrane rolls and modules

A technology of spiral winding and membrane roll, which is applied in the direction of membrane, membrane technology, semi-permeable membrane separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention relates to a spirally wound film roll and a film assembly including such a spirally wound film roll in a housing body, as described in further detail below and in the pending claims.

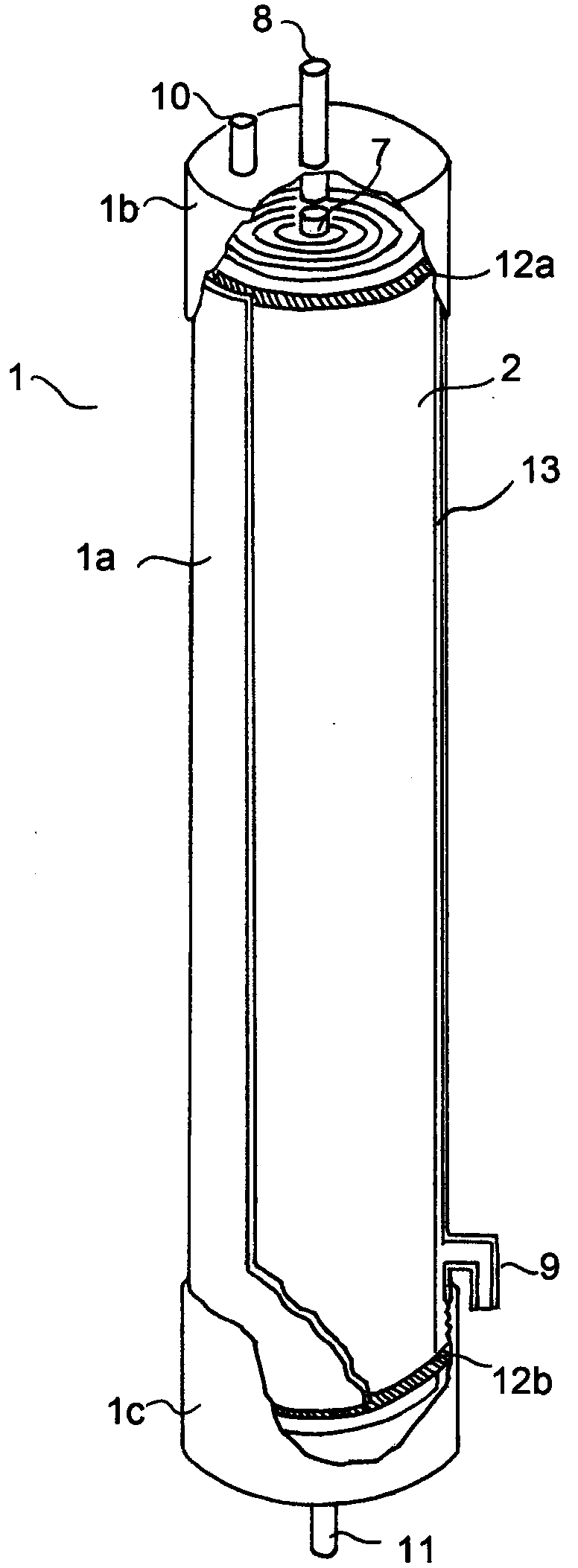

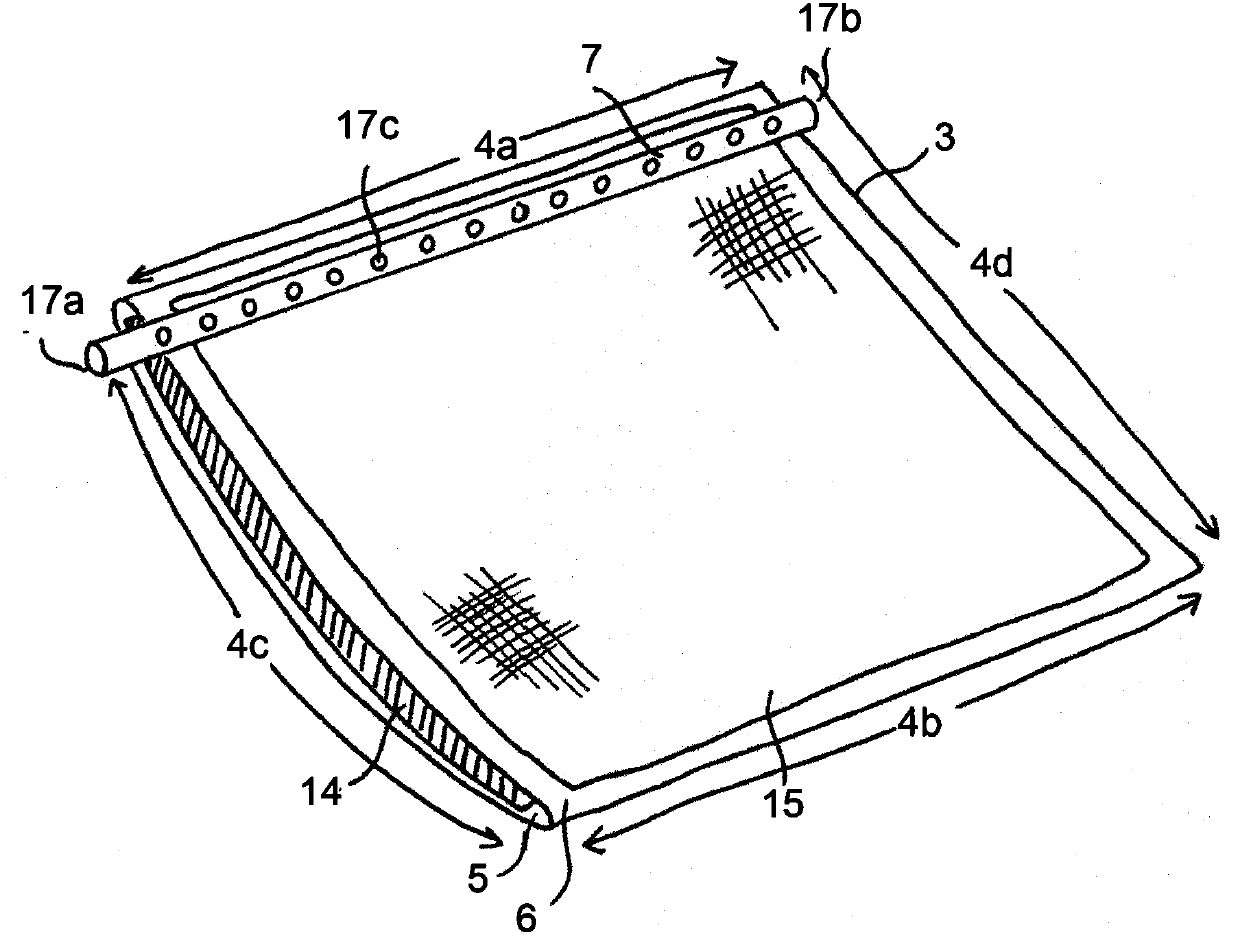

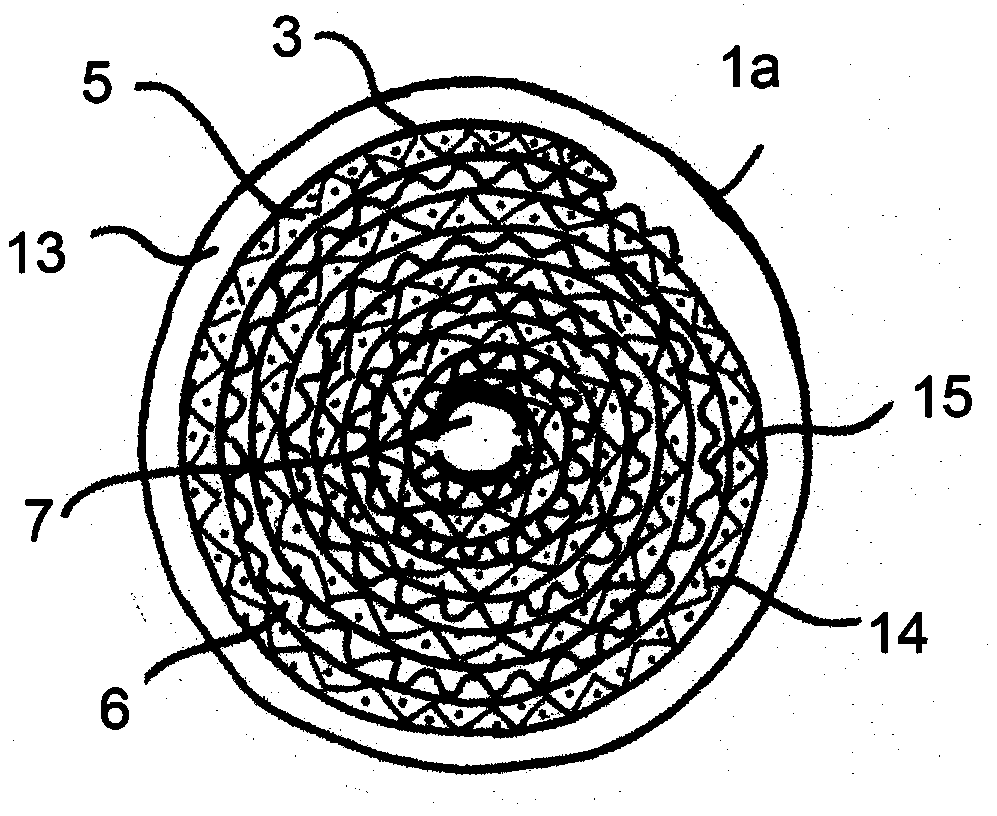

[0053] figure 1 The spiral wound membrane module according to the present invention is shown. The housing body of the spirally wound membrane module 1 includes a device for defining the housing chamber area 13. In one embodiment, the housing body includes a housing body cylinder 1a and two end caps 1b, 1c. The housing body further has a device for an inlet 8 for the second aqueous liquid, which device is in fluid communication with the central tube 7. Furthermore, the housing body has a device for an outlet 9 for the second aqueous liquid, which is in fluid communication with the housing chamber space 13. The means for the outlet of the second aqueous liquid may be in the form of a plurality of openings extending along the length of the central tube. In one embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com