An online soft-sensing method for power plant incoming coal quality combining mechanism and brain-inspired intelligence

A soft measurement and coal quality technology, which is applied in the field of online soft measurement of coal quality entering the furnace in power plants, can solve the problem of optimal control of fire-resistant coal thermal power units, difficulty in guiding the energy-saving power generation scheduling plan of coal-fired power plants, and inability to analyze coal quality components online in real time, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

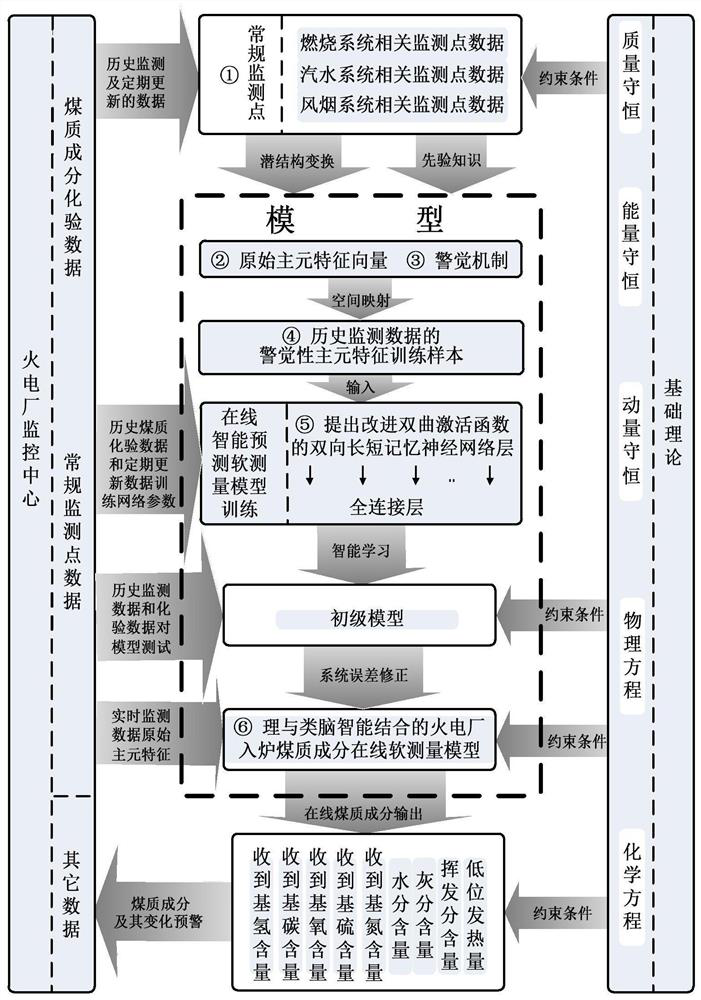

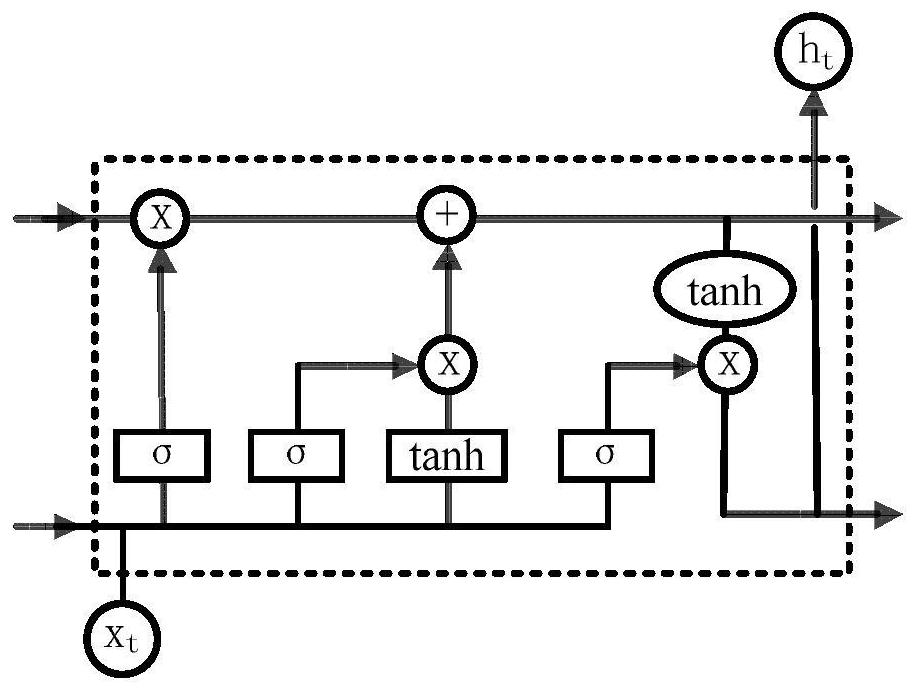

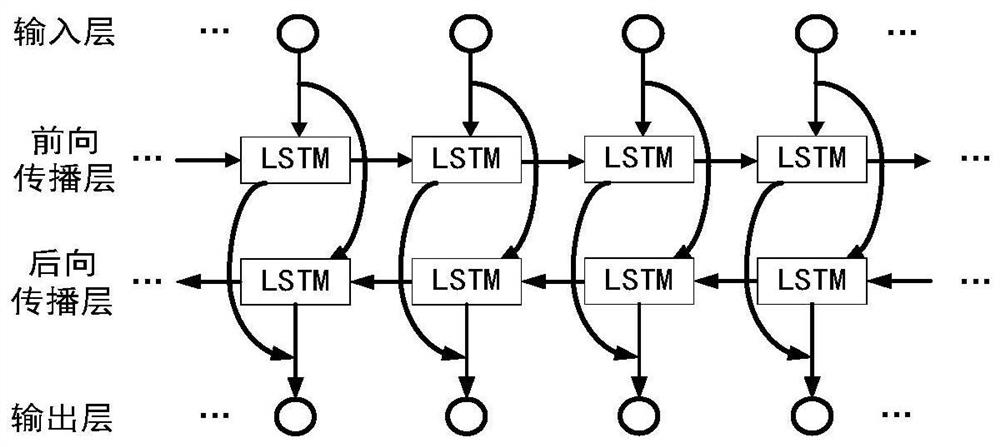

[0066] The method of the present invention is based on the basic theories of coal quality analysis such as energy conservation, mass conservation, momentum conservation and physical and chemical equations in the production process of the thermal power plant, and utilizes the historical big data of the conventional monitoring points of the thermal power plant and the historical data of the conventional coal quality test. Create an online coal quality composition soft-sensing model with an intelligent method; use real-time data from conventional monitoring points in thermal power plants to realize industrial monitoring of the carbon, hydrogen, oxygen, nitrogen element composition, moisture content, volatile matter content, ash content, and low calorific value of the incoming coal. On-line intelligent soft measurement of components, research ideas and technical routes refer to figure 1 .

[0067] (1) Propose the conventional monitoring points and soft measurement output parameter...

Embodiment 2

[0142] Embodiment 2 of the present invention proposes an online soft-measurement system for coal quality in a power plant that combines a mechanism with brain-like intelligence. The system includes:

[0143] A pre-established online soft-sensing model of coal quality in thermal power plants;

[0144] The data collection module is used to collect the monitoring data of 190 routine monitoring points in real time;

[0145] The soft measurement value calculation module is used to extract the original principal component feature of the monitoring data, input it into the online soft measurement model, and output the soft measurement value of the online element composition and industrial composition of coal quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com