Lens defect detection method based on stripe deflection

A defect detection and lens technology, applied in measurement devices, phase influence characteristic measurement, material analysis by optical means, etc., can solve the problems of easy introduction of human error, increase labor cost, slow manual detection speed, etc., and achieve high-precision detection. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described below with reference to the drawings and examples.

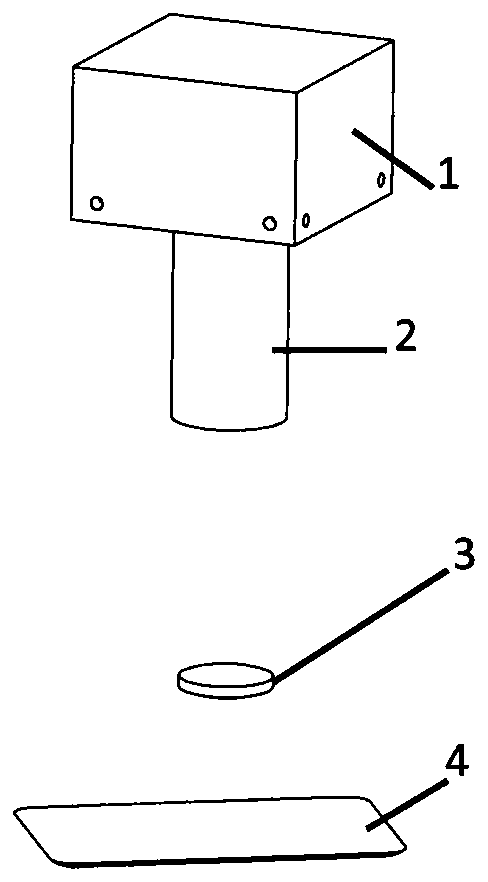

[0025] Such as figure 1 As shown, the main structures required by the lens defect detection method provided by the present invention include an industrial camera 1, a telecentric lens 2, and an LCD screen 4. The LCD screen is used to project sinusoidal fringes, the lens 3 is placed above the LCD screen, and the camera 1 shoots above the lens. The detection principle is as figure 2 As shown, when the lens 3 has a defect 5, it will inevitably affect the light refraction of the lens and cause the light to be deflected, as shown by the dotted line in the figure, which will cause the fringe image captured by the camera to change, and the specific fringe changes Such as image 3 Shown. Under normal circumstances, when the screen displays sinusoidal fringes, the camera will also capture uniform sinusoidal fringes 6 through the lens. When the lens is defective, it is reflected in the cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com