Hot bending furnace for glass

A hot bending furnace and glass technology, applied in glass production, glass molding, glass manufacturing equipment, etc., can solve the problems of difficult maintenance, difficult production, and large space occupied by hot bending furnaces, and achieve compact arrangement, installation and maintenance Simple and convenient maintenance, convenient post-maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

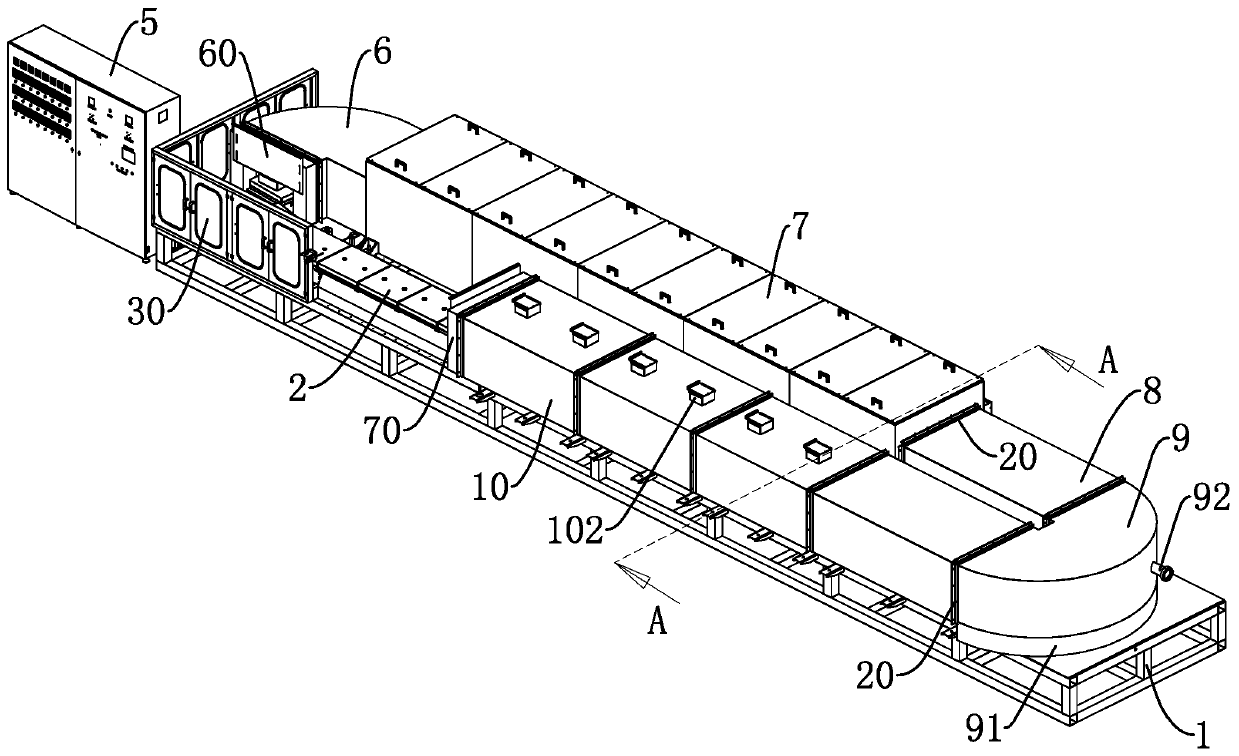

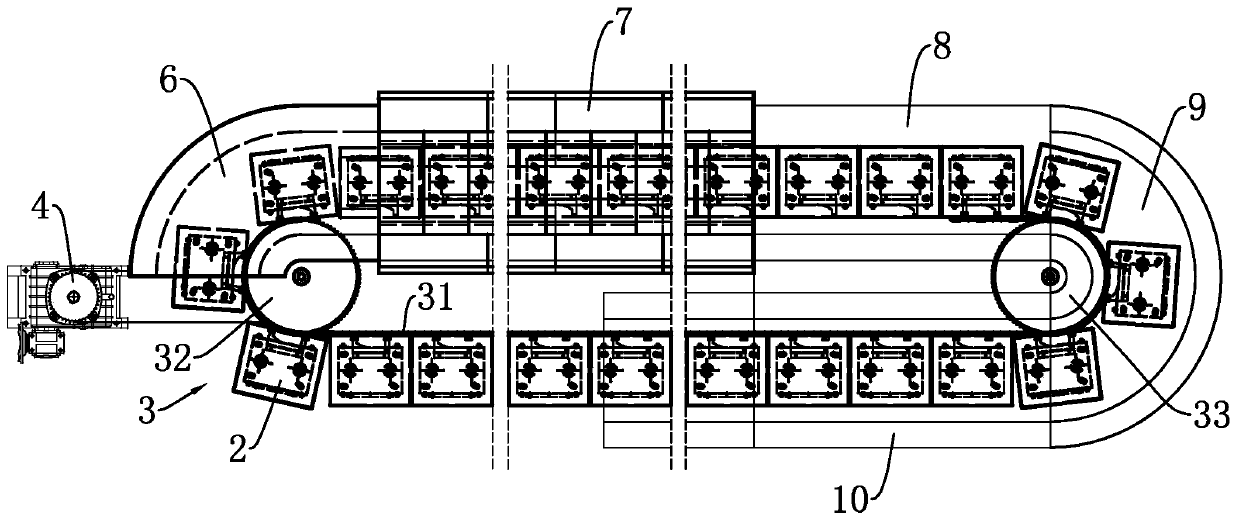

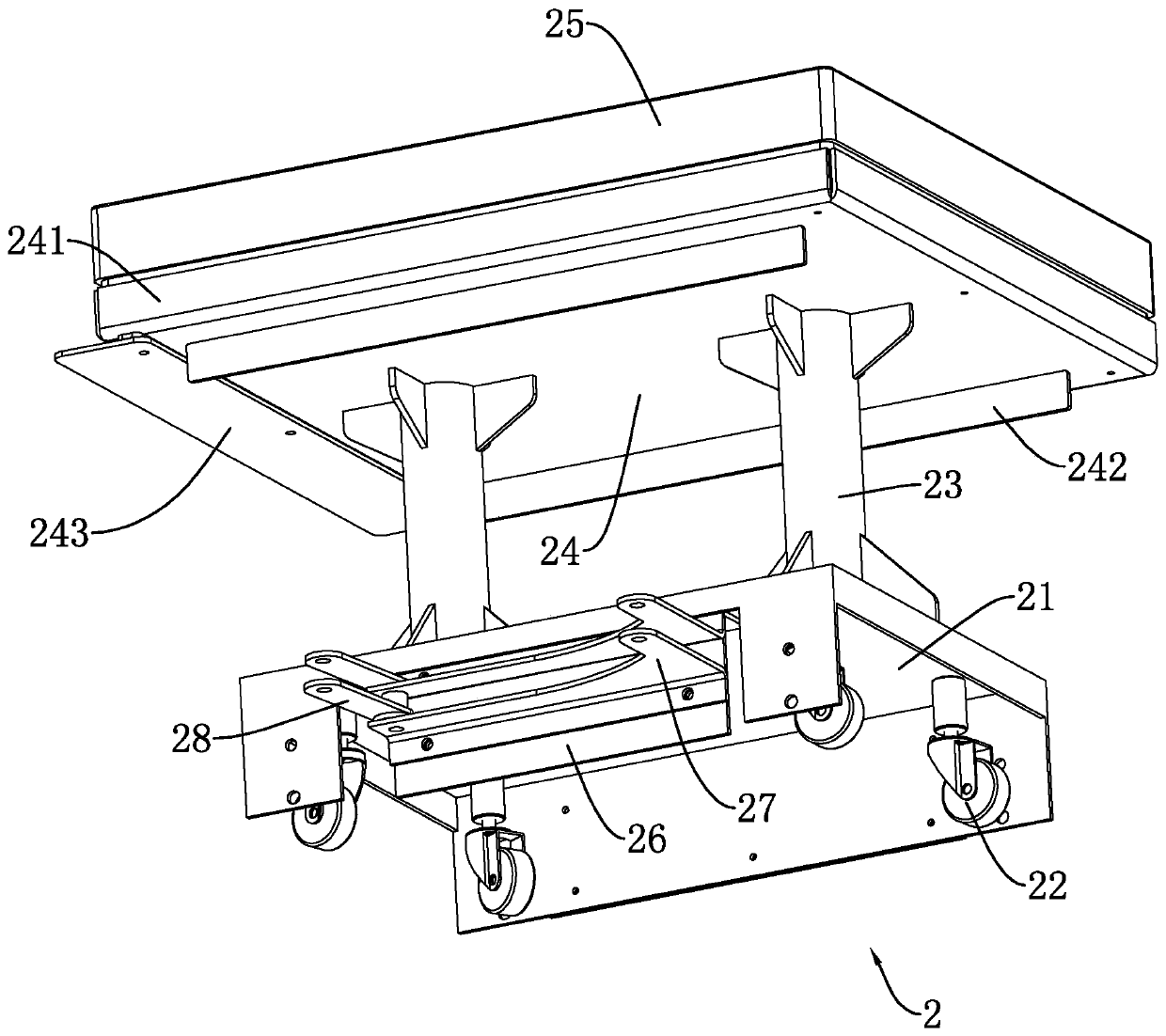

[0043] Embodiment 1: a kind of glass hot bending furnace, such as figure 1 , figure 2 As shown, it includes a rectangular frame 1 formed by welding a plurality of horizontally and vertically staggered square tubes. The upper end of the frame 1 slides and supports a material trolley 2, and the frame 1 is provided with a driving device 3 that drives the material trolley 2 to move. , the driving device 3 includes a chain guide rail 31 distributed in the shape of "back", the material trolley 2 is fixedly connected to the outer ring surface of the chain guide rail 31, and the frame 1 is provided with a power device 4 that drives the chain guide rail 31 to rotate. One side of 1 is also arranged with electric control box 5.

[0044] The upper end of the frame 1 is sequentially provided with a U-shaped feeding section 6, a thermal bending section 7, a first straight cooling section 8, a U-shaped discharging section 9 and a second straight cooling section 10 along the running directi...

Embodiment 2

[0071] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the glass bending furnace of this embodiment is provided with a vacuum device 70 that provides negative pressure. It is difficult to meet the requirements of deep curvature. At this time, it is necessary to use external force (such as negative pressure adsorption) to assist natural collapse, so that the product meets the technical requirements.

[0072] The vacuum device 70 is arranged in the frame 1, directly below the running track 12 in the thermal bending section 7, as Figure 8 As shown, the vacuum device 70 includes a linear sub-rail 701 fixed on the bottom of the frame 1, a fixed seat 702 slidably mounted on the linear sub-rail 701, and an ejector cylinder 703 fixed on the fixed seat 702 with the output end distributed vertically upward. , the connecting seat 704 fixedly connected to the output end of the ejecting cylinder 703, the suction cup 705 installed on the upper end of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com