Cotton and linen textile cloth anti-wrinkle conveying device

A technology for textile fabrics and conveying devices, which is applied in the directions of thin material handling, transportation and packaging, and winding strips, etc., can solve the problem of easy wrinkling of fabrics, and achieve the effect of strong practicability and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

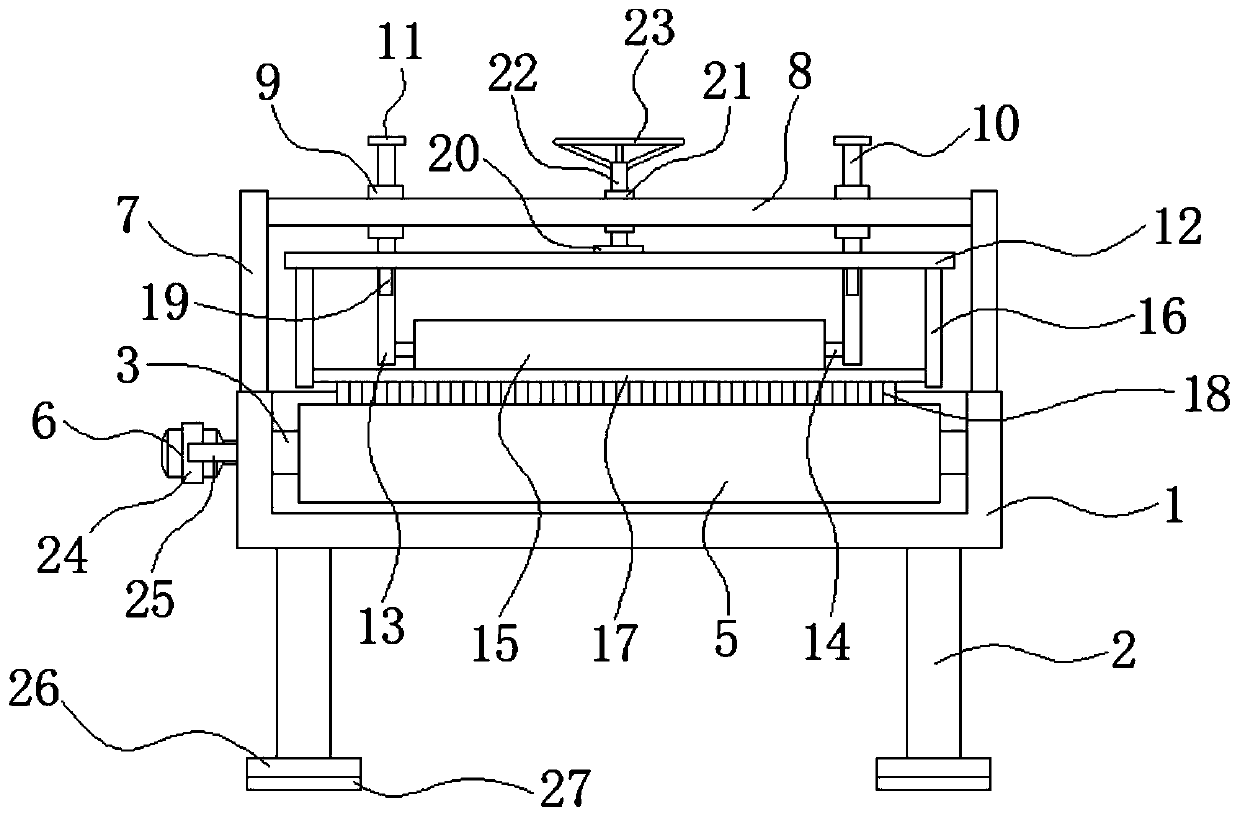

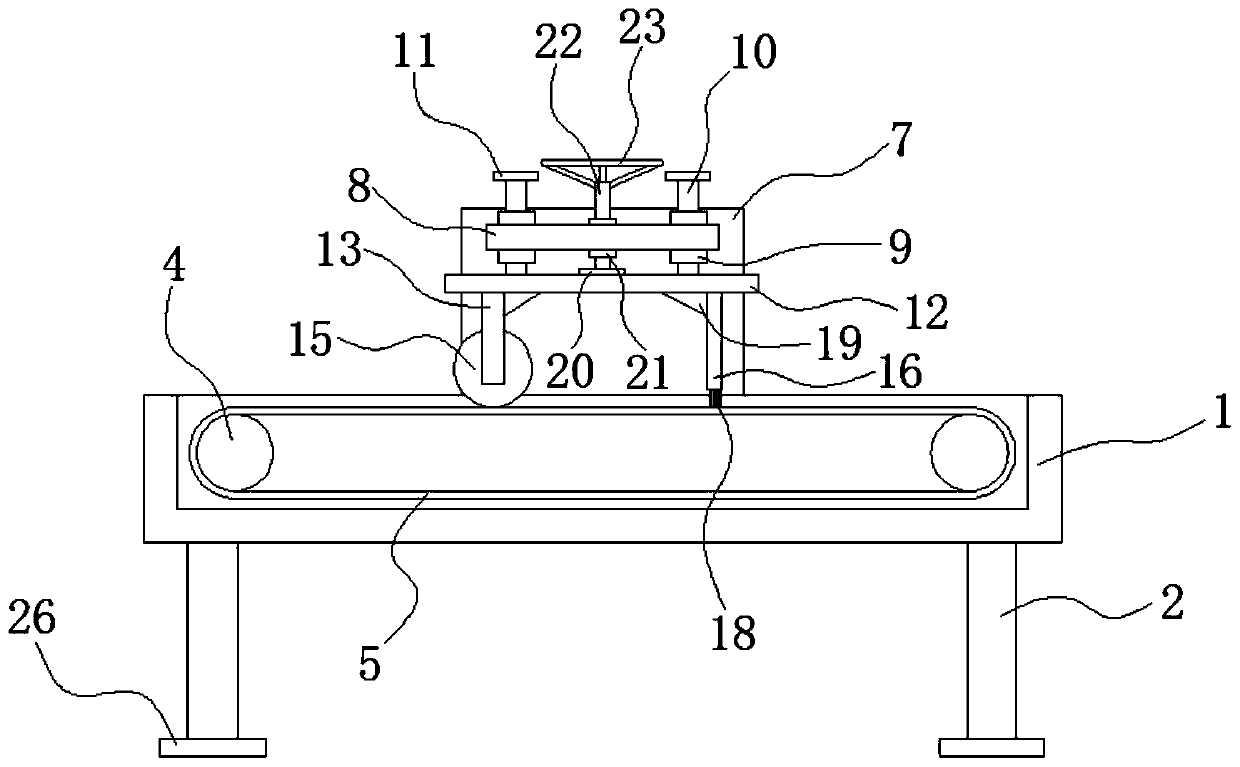

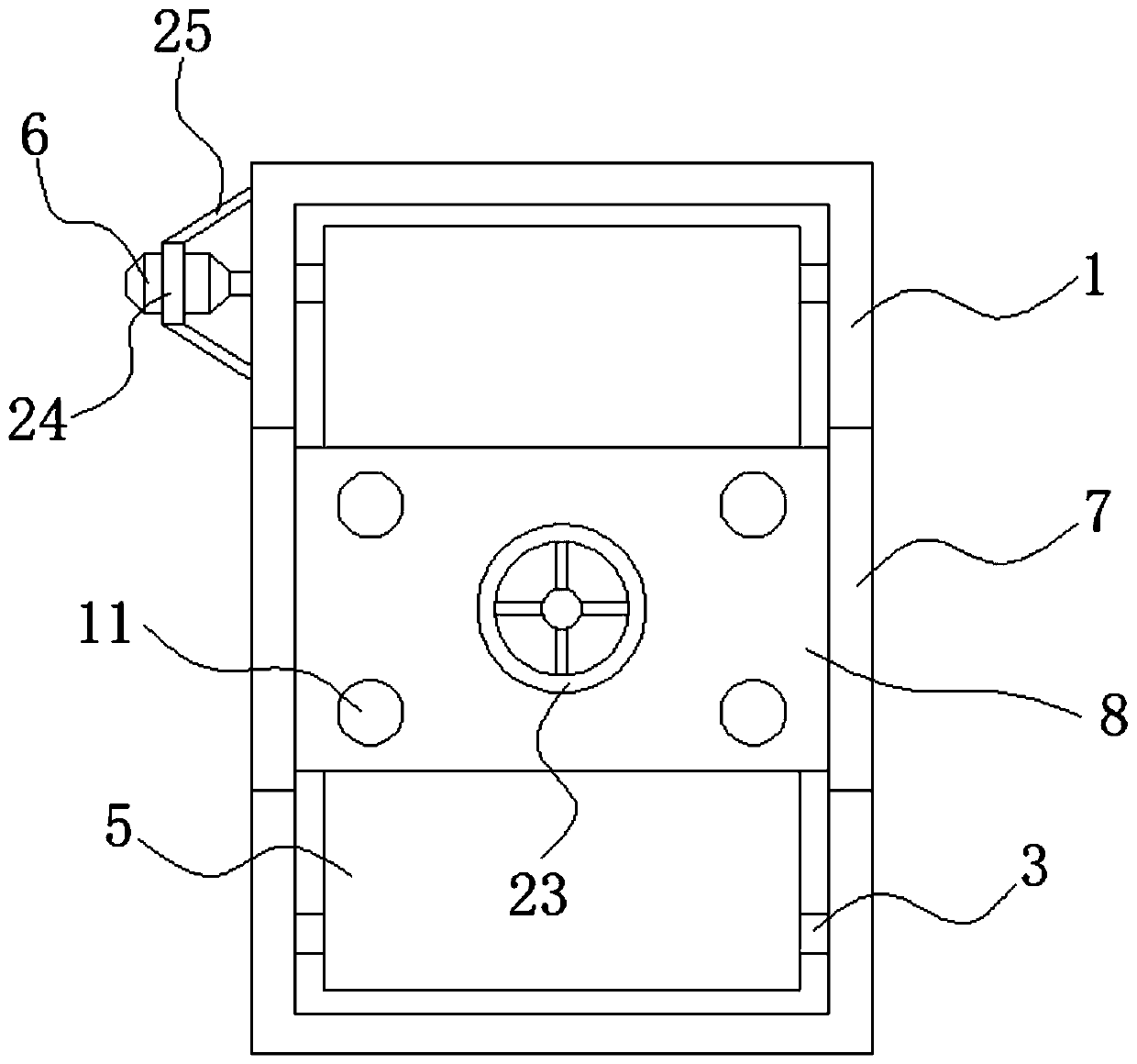

[0017] refer to Figure 1-3 , a wrinkle-proof conveying device for cotton and linen textile fabrics, comprising a conveying trough 1, four corners of the bottom surface of the conveying trough 1 are fixedly welded with support columns 2, the bottom of the support columns 2 is fixedly welded with a support plate 26, and the support plate 26 A layer of anti-slip mat 27 is fixedly adhered to the bottom surface, and the setting of anti-slip mat 27 can increase the stability of the entire conveying device.

[0018] In the present invention, two symmetrical support round rods 3 are rotated at both ends of the transfer trough 1, and the outer fixed sleeve of the support round rod 3 is provided with a first roller 4, and the two first rollers 4 are sleeved with a The belt 5, one end of the support round rod 3 extends through the transmission trough 1 to the outside of the transmission trough 1, the outside of the transmission trough 1 is equipped with a drive motor 6 through a fixing ...

Embodiment 2

[0022] refer to Figure 1-2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the lifting mechanism includes a turntable 20 fixedly installed in the middle of the connecting plate 12 and a threaded sleeve 21 fixedly arranged in the middle of the support horizontal plate 8, the threaded sleeve 21 internal threads are connected with a threaded rod 22, the bottom of the threaded rod 22 is fixedly connected with the turntable 20, the top of the threaded rod 22 is fixedly welded with a roulette 23, and the rotation of the roulette 23 makes the threaded rod 22 start to rotate. The threaded sleeves 21 are threadedly connected, so that the threaded rod 22 can move up and down in the threaded sleeve 21 , so that the connecting plate 12 moves up and down together with the threaded rod 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com