A telescopic shaft positioning and pressing device pin bilateral cutting device

A technology of cutting device and telescopic shaft is applied in the field of double-sided cutting device for positioning and pressing device pins of telescopic shaft, which can solve the problems of low efficiency and poor consistency, and achieve the effects of high positioning, low manufacturing cost and good centrality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

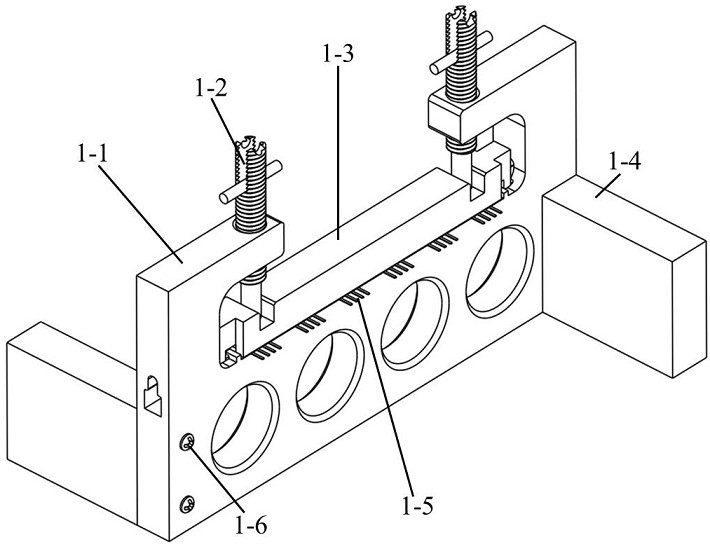

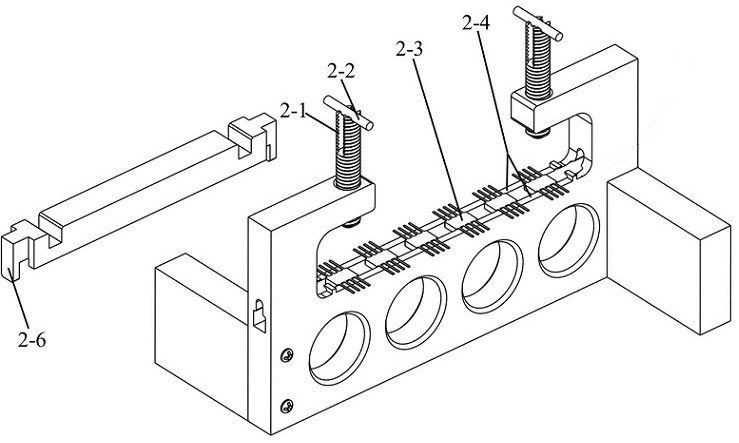

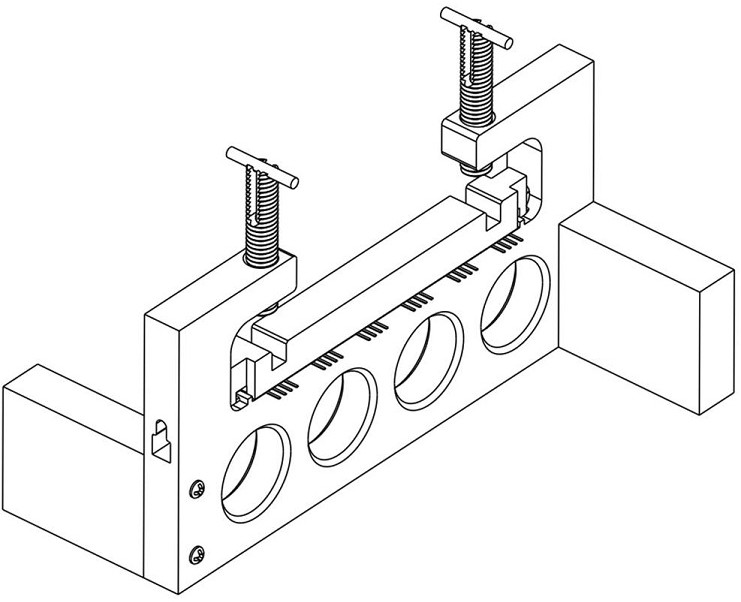

[0040] The pins of a ceramic small outline package device need to be trimmed, and the metal pins protrude from the bottom of the device and are symmetrically distributed on both sides. The device body is made of ceramics, and the place where the ceramic body contacts the metal pins is brazed and welded, and the strength is weak. Such as figure 2 , place the device in the pin cutting device, first pull up the 2-2 telescopic shaft pull rod, rotate it 90° and place it in the groove on the top of the 2-1 telescopic shaft body, at this time the telescopic shaft final shaft retracts upward threaded telescoping shaft body. Then several devices 2-3 are placed in the groove with the body facing down, and the size of the body matches the width of the groove.

[0041] With the telescopic shaft kept pulled up, place the limit pressure block under the telescopic shaft and above the notch. Insert the pressing block boss 2-6 into the groove, and then put down the pressing block as a whol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com